Kverneland 3400 S

Plough | Reversible plough

High output for in-furrow/on-land operations and low maintenance costs

On-land & In-furrow New Generation of mounted reversible ploughs. 5 - 7 furrows

The advantages of this Reversible plough

- Efficient parallel linkage system for smooth turnover

- Ideal for tractors having dual wheels or rubber track

- Aero-profile high legs for best soil flow performance

- Quick central adjustments of skimmers

- Vary-Width® or easy mechanical width adjustment

Description

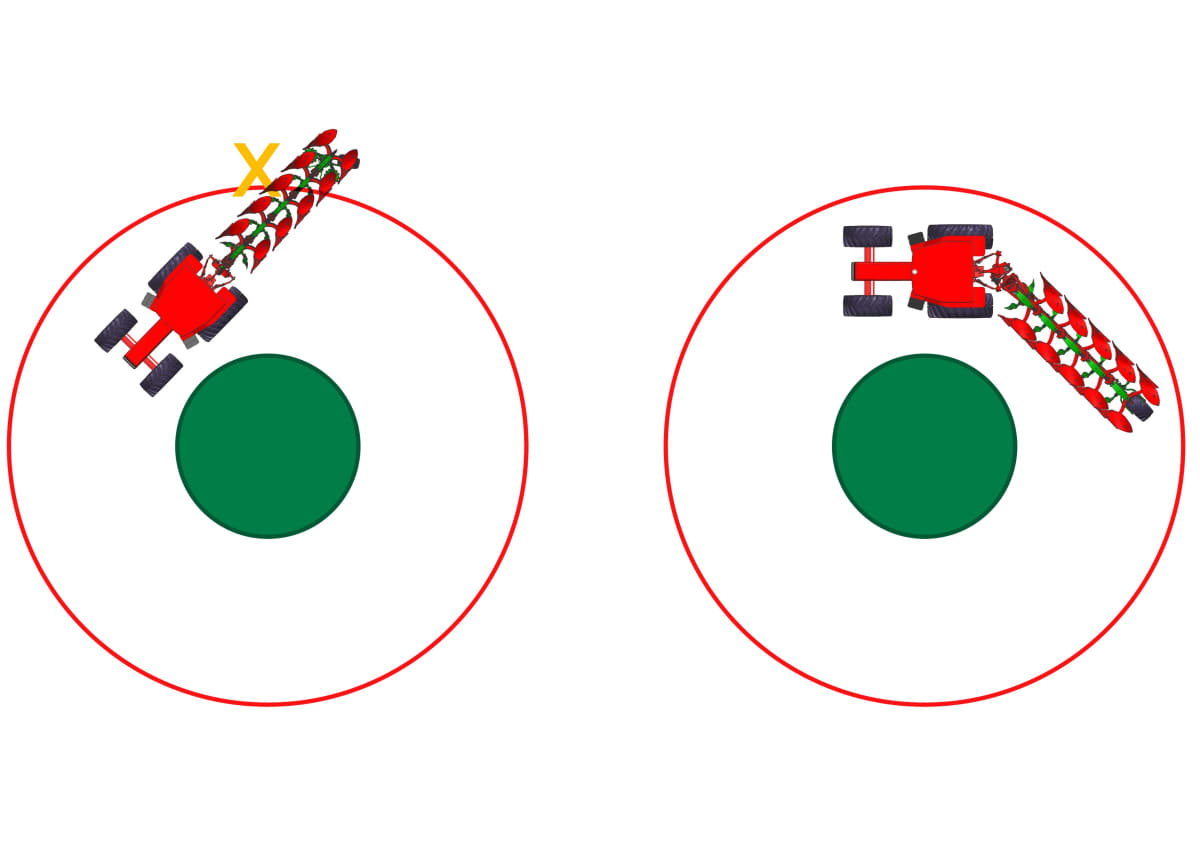

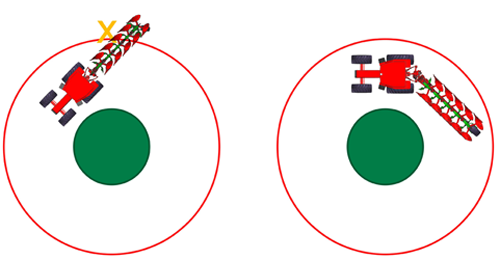

Designed for In-Furrow and On-Land operations. Easy swap from one another: the driver has fingertip control. The Kverneland 3400 S stepwise offers comfort with lower lift requirements than other brands. Easy manual working width adjustments in steps of 5cm (2") The headstock No 300 provides the necessary strength for a smooth reversing. Robust frame 120 x 200 mm. In its on-land configuration the plough’s massive offset (up to 3,85 m) allows the tractor to be positioned exactly to the drivers’ requirements.

Highlights

- Smooth turnover action thanks to an efficient parallel linkage system which hydraulically moves the plough into a balanced position

- Ideal for tractors having dual wheels or rubber track

- Aero-profile high legs for best soil flow performance

- Quick central adjustments of skimmers for the perfect ploughing

- Optional automatic front furrow adjustment. Mechanical front furrow adjustment is standard

- Unique wheel memory system that maintain desired working depth settings after the reversing cycle

- Safe transport: Kverneland Trailer Transport Solution (optional)

- Efficient re-consolidation in one pass. Kverneland Packers and packer arm compatible

Features

Features

Stepless Vari-width® system for infinite adjustments of working width. Kverneland’s world patented system is available either with hydraulic or mechanical furrow adjustments.

Benefits:

- Easy variation of ploughing capacity

- Perfect match at all time between tractor capacity, implement and soil conditions

- Time saving: up to 30% more capacity

- Cost saving: up to 18% reduction in fuel consumption in relation with increased ploughing capacity

- Better work: plough up to the hedges, fences, trees and ditches

- Minimum wear: unique non-wearing linkage joint between the beams and the mainframe section

- Perfect line of pull at all time. Kverneland’s Vari-width offers the correct parallel linkage along the whole plough. Therefore, lower draft requirement, minimum wear and tear.

Excellent Ploughing Quality

They are renowned all over the world for their:

- excellent ploughing quality

- outstanding wear resistance

- low draft requirements

Bodies of a unique steel.

Kverneland Technology: 12 hours carburising heat treatment process for:

- optimum wear resistance (sharp as a diamond)

- the necessary flexibility to absorb impacts

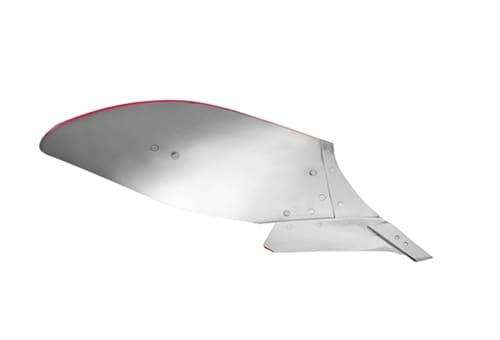

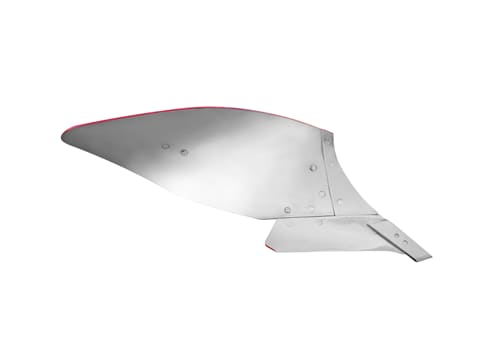

Body No. 8 – “Universal body”

for light to heavy soils

good trash burial

easy pulling

Depth: 15 to 30 cm (6 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 9 – “Deep Universal body”

for heavier soils and deeper ploughing

well turned and packed furrows

easy pulling

Depth: 15 to 35 cm (6 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 28 – “Wide tyre body”

suits all soils; even heavier soils than body 8

very wide empty furrow for tractor wheels up to 710 mm

good turning and well packed

easy pulling

suitable for Depth: 12 to 30 cm ( 5 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 30 – “Finger body”

for sticky-stony soil and abrasive soils

good work in heavier soils

best crumbling effect

wide furrow bottom,

Depth: 20 to 35 cm (8 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 34 – Plastic mouldboard

Long and slim shape (similar to body 28)

For soils with high humus content without stones

Advised for tactors with large tyres

Easy pulling

Working depth: 12-35cm

Working width: 30-55cm

Landside / mouldboard: 40 degree

Body No. 38

universal body – easy to pull

for any soil conditions

recommended for tractors with large tyres

from deep to shallow ploughing

perfect turning of the furrow slice

working depth: 12-35 cm

working width: 30-55 cm

landside / mouldboard: 40°

Kverneland Heat Treatment Technology:

- more than 140 years of experience

- steels that withstand the toughest of conditions

- best robustness/weight ratio on the market

- for equivalent robustness, competitors would add more steel and therefore more weight, quicker wear, dissappointing ploughing results

Kverneland Steels:

- Benefits from less weight:

easier to pull/lower fuel consumption/lower lift requirement/reduced wear and stress for the tractor/more economical … - Benefits from more resistance:

minimum breakage/less maintenance/lower rotation for wearing parts/time saving/highest 2nd hand plough value/longer life for the plough/more economical…

Problems always happen when the plough is being used, when the work must be done!

A Kverneland plough is a peace mind!

More info: Kverneland Technology

Kverneland “TTS” (Trailer Transport Solution)

- The plough behaves like a trailer. Turnable cross shaft max. 45° mutual offset during transport.

- Safe: maximum security for anything/anyone around and for the driver. No tilting out when driving in curves.

- Easy conversion from transport to ploughing.

- The Kverneland TTS is an option

Aero-profile legs

- Special design for best soil flow.

- 80 cm leg height to prevent potential blockage in heavy residues, manure, cover crops or when ploughing deeper.

- Robust legs: pre-shaped components limiting weldings.

- Low pulling requirement and hence fuel consumption thanks to low weight hollow legs.

Auto-reset system

- Unrivalled Kverneland mechanical leaf spring system for Non-stop ploughing.

- No Maintenance.

- Legs, plough and tractor lives are protected and lengthened.

- Quality ploughing: legs release independently one from another and come back to the correct position.

- Easy adjustment of releasing forces: unscrew 2 bolts to add or remove springs.

Leaf springs |

Release Pressure kN |

Standard pack: 6 leaf springs |

11,2 |

HD pack: 7 leaf springs |

12,7 |

XHD pack: 8 leaf springs |

14,4 |

Double pack: 6+4 leaf spring |

16,9 |

Smart skimmers adjustment

- Unique: central adjustment of skimmers working depth.

- Quick operations: right and left skimmers adjust simultaneously.

- High ploughing performance: the correct adjustment of skimmers contribute to a quality ploughing.

- Disc coulters also available: plain or notched (18”/45cm or 20”/50cm)

Importance of heat treatment

- The frame is an essential part of the plough construction. For Kverneland quality standards, a non heat treated part is a weak part!

- Kverneland frames are heat treated by induction twice. The temperature transfer to the steel is closely monitored. The frame gains 3 times as much strength. This unique Kverneland induction processes provides robustness and flexibility while ensuring an outstanding durability.

Stronger but not heavier

- For the equivalent Kverneland robustness, competitors would use more steel in thickness or in dimensions, therefore producing a heavier frame.

- Heavier frame impacts negatively pulling forces, wearing of parts, lifting capacities, tractor life time, and fuel consumption.

Long lasting

- Weldings are also a critical weakness for a plough frame. Kverneland frames are supplied as one sole part!

Technical specifications

Technical specifications

Download brochure| Model | 3400 S | |

|---|---|---|

| Interbody clearance cm | 85/100 | |

| Head- stock | Nº 300 | |

| Leg protection | Auto-reset | |

| Working width cm | 35-40-45/35-40-45-50 | |

| Underbeam clearance cm | 80 | |

| No. of furrows | 5-7 (6+1)/5-6 | |

| Weight (kg), 5 furrows | 2100 | |

| Weight (kg), 6 furrows | 2280 | |

| Weight (kg), 7 furrows | 2500 | |

| Lift requirement (kg), 5 furrows | 6600 | |

| Lift requirement (kg), 6 furrows | 7600 | |

| Lift requirement (kg), 7 furrows | 8750 |

Technical specifications

Technical specifications

Download brochureModel |

Interbody clearance cm |

Head stock |

Type of beam |

Working width cm |

Under beam clearance cm |

No of furrows |

3400 S |

85 |

No 300 |

Auto-reset |

30 - 50 |

80 |

5 - 7 |

3400 S |

100 |

No 300 |

Auto-reset |

35 - 55 |

80 |

5 - 6 |

3400 S Variomat |

85 |

No 300 |

Auto-reset |

30 - 50 |

80 |

5 - 7 |

3400 S Variomat |

100 |

No 300 |

Auto-reset |

35 - 55 |

80 |

5 - 6 |