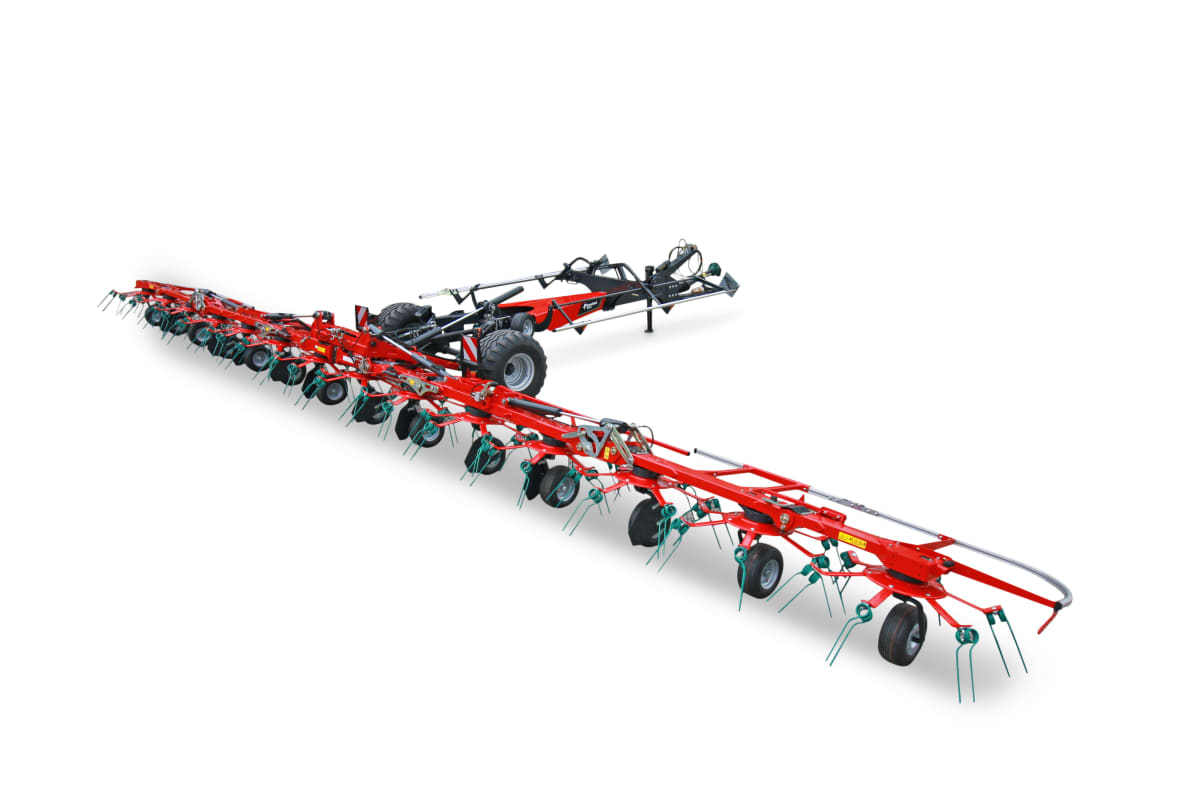

Kverneland 85156 C

Tedder | Trailed Tedder

High capacity, excellent ground tracking

Trailed tedder with transport chassis

The advantages of this Trailed Tedder

- TerraFlow ground following system provides a highly adaptive frame connection and adaptation to ground contours

- Very easy operation - only one single and double acting outlet needed

- 12 - 14 small diameter rotors for excellent crop turning in all conditions

- Compact, easy transport due to trailed concept

- High clearance in headland position

Description

Kverneland 85156 C, with 15.6m working width, is a carrier frame tedder purpose-built for heavy duty use. The wide track width ensures stable running characteristics during road transport. Optional 500 mm wide wheels support ground protection. The new, innovative TerraFlow ground following system provides a highly adaptive frame connection allowing the tedder moving independent of the carrier for perfect contour following. The high flexible frame allows the 14 rotors to accurately follow ground contours. Featuring 14 small diameter rotors, this tedder is designed for excellent crop turning in almost any conditions. Due to the carrier frame concept, the lifting capacity of the tractor is not a limiting factor and it can be operated with smaller tractors. The special developed folding sequence secures a safe and fast unfolding also in hilly conditions. A sequence control prevents damages. With the high focus on maintenance free joints, hinges and gearboxes, the maintenance level in season is reduced to the lowest level in class.

Highlights

- Fully maintenance-free in season, except PTO and carrier

- Strong maintenance free driveline, sturdy u-joints on the inside rotors and flexible HexaLink finger clutch on outside rotors

- Innovative TerraFlow ground following system between carrier and tedder

- Transport running gear for use with low HP tractors

- Clever unfolding also in hilly conditions

- Optional hydraulic foldable swath board for border tedding

Features

Features

- TerraFlow is an innovative ground following system between carrier and tedder. The special geometry between transport wheels and tedder tines secure a clean pick up of crop, also in very challenging conditions.

- The tedder unit follows the chassis wheels and adapts completely independent of the movement of the carrier frame. This means tine distance to ground remains constant in all terrain, providing clean and accurate work and a uniform crop flow.

- These tedders fold into a transport width below 3m and is driven like a trailer on road smoothly following behind the tractor.

- To connect the machine 40 and 50 mm towing eyes are available as well as a K80 ball coupling. The machine can be connected in high or low position of drawbar.

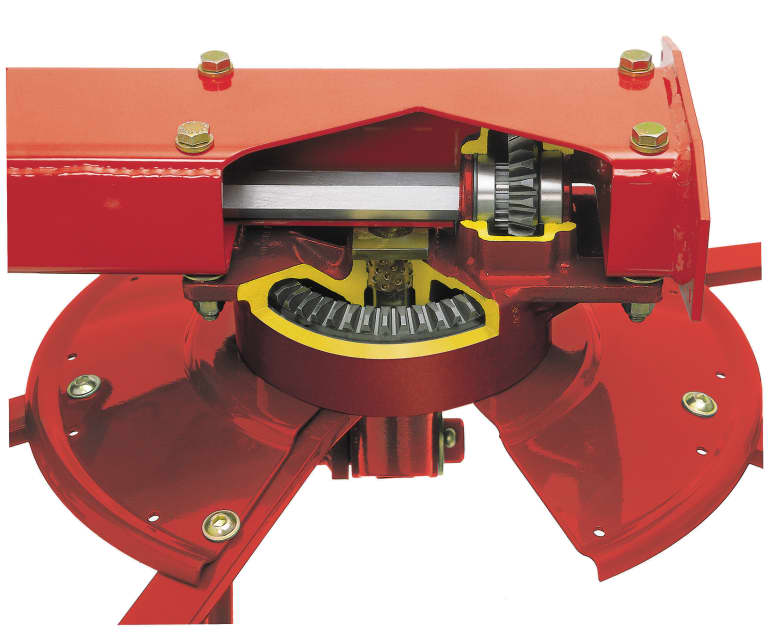

- The ProLine gearbox is a strong and reliable construction, and is not fitted to the mainframe.

- Shock-protected: The enclosed system is not affected by chassis or tine arm vibrations.

- Constant lubrication: Enclosed and oil-immersed, the gearbox components enjoy extended longevity over systems that require manual lubrication.

- Reduced maintenance: There is no need for daily lubrication.

- Environmental protection: No lubrication means no leakage - hence higher-quality forage.

- No corrosion: No ingress of dust and water, not even during pressure washing.

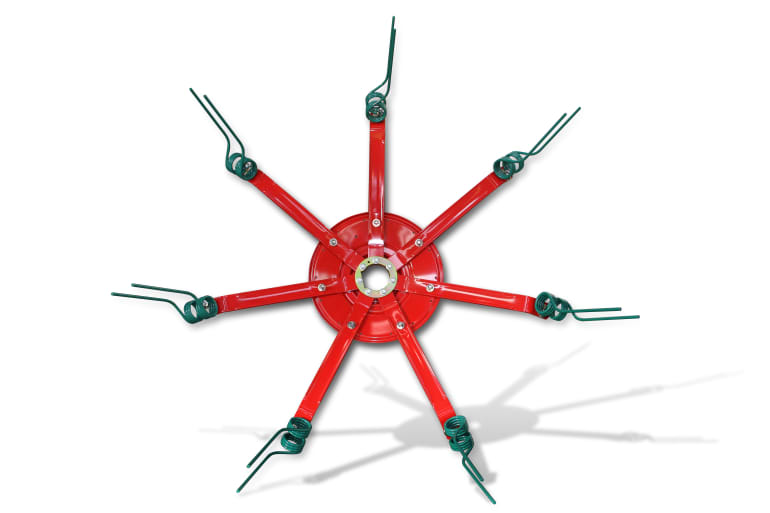

- The Super-C tine can be locked in three positions to customize the pickup angle to different conditions. For heavy silages the angle can be set more aggressive and for fragile crop a gentler angle can be chosen.

- Made from flat steel, the tine arms form a very compact unit with the rotor plate and utilize the force of the rotor plate for higher durability of the time arm. This makes a Kverneland tine arm by far more resistant to any type of load.

- Super-C tine with symmetric spring tines ensures efficient pick-up and turning of the crop. Tines with same lengths has the added advantage that load is spread evenly on both tines, providing longer life time.

- Made from 10mm shot-peened spring steel and a coil diameter of 80mm, Super-C tines add up to the most durable and flexible tine in the market.

- High-quality forage allows the optimum spreading angle to be achieved according to crop conditions, helping you to produce high quality forage.

- Setting the rotors to the right spreading angle will considerably improve the spreading action, and speed up the drying process.

- The mower swaths are neatly lifted by the tines and evenly spread over the full width.

- Tines glide in a more uniform frequency over the stubble, so the risk of dirt being lifted by the tines is minimized.

Powered by a maintenance-free driveline and gearboxes, focus can be directed towards the essentials to maximise productivity. No time is wasted on time consuming greasing. Additionally the hinges are connected with strong maintenance-free roller bearings for extended longevity and stability of the connection points.

Technical specifications

Technical specifications

Download brochure| Model ProLine | 85156 C | |

|---|---|---|

| Working width (m/ft) | 15.60 / (51'2") | |

| Number of rotors | 14 | |

| Number of tines/rotor | 6 | |

| Transport width (m/ft) | 2.98 / (9’9”) | |

| Transport length (m/ft) | 6.40 / (21') | |

| Storage height (m/ft) | 2.89/3.20 / (9'6"/10'6")** | |

| Capacity theor. (ha/h) | 12.5 |

** Height with hydraulic swath board |

Technical specifications

Technical specifications

Download brochure

|

Working width |

Rotors/Tines |

Weight |

85134 C |

13.40m |

12/6 |

3195kg |

85156 C |

15.60m |

14/6 |

3410kg |

** Height with hydraulic swath board |