Kverneland Satio F

Seeder | Pneumatic solo seed drill

Effective cost-efficient sowing – with flexibility ready for the future

Folding solo seed drill with compact design for small and medium tractors

The advantages of this Pneumatic solo seed drill

- Compact & lightweight design - low power requirement

- Flexible - sowing independently from seedbed preparation

- Precise seed placement

- Cost-efficient

- High sowing speeds - large performance

Description

The compact solo seed drill Kverneland Satio F is available in working width of 5.0m and 6.0m. In solo seeding operation, the Kverneland Satio offers extra flexibility to adapt also to extreme weather conditions. Only low power requirement is needed due to a close centre of gravity. Higher sowing speeds and a high performance can be achieved. The seed hopper offers a large capacity of 1,700l. The Kverneland Satio F is available as e-bas and e-com model. Both models are equipped with the electric ELDOS metering device. The Kverneland Satio F e-bas is not ISOBUS compatible and the electronic control is ensured by the Focus 3 terminal. The Kverneland Satio F e-com model on the other hand is fully ISOBUS controlled and can be steered by the Kverneland Tellus 700, the Kverneland Tellus 1200 or any other terminal.

The CX-II coulters, with or without press wheels, are clamped to the coulter bar and allow the adaptation to individual farming systems by choosing the right row spacing of 12.5cm or 25cm. The coulter pressure is adjusted mechanically or can be controlled hydraulically from the cab. The sowing depth is centrally adjusted via spacers. Press wheels support the fine adjustment of the sowing depth and increase soil-to-seed contact for fast emergence. Integrated track eradicators are standard

A full range of options like pre-emergence markers, S-tine following harrow, road light kit or LED working lights are available to customize to individual needs.

What are the benefits of a solo seed drill ?

The Kverneland Satio Solo Seed Drill is designed for modern farmers who want precise, efficient, and sustainable sowing, without depending on seedbed preparation. This solo operation gives you maximum flexibility and more control over timing, sowing depth, and soil conditions, delivering higher yields and lower input costs. Solo drilling extends your operational window and helps balance seasonal workload peaks since you are not tied to other fieldwork schedules. The Kverneland Satio allows faster working speeds and precise seed placement also at shallow depth. This means more hectares in less time without compromising on accuracy.

Reduced soil compaction and fuel costs

Solo drilling requires less tractor power, minimizes soil compaction, and reduces fuel consumption.

Better weed and pest control

Featuring the advanced CX-II coulter, the Kverneland Satio ensures accurate seed placement with minimal soil disturbance. This enhances mechanical weed control and supports integrated pest management strategies.

Features

Features

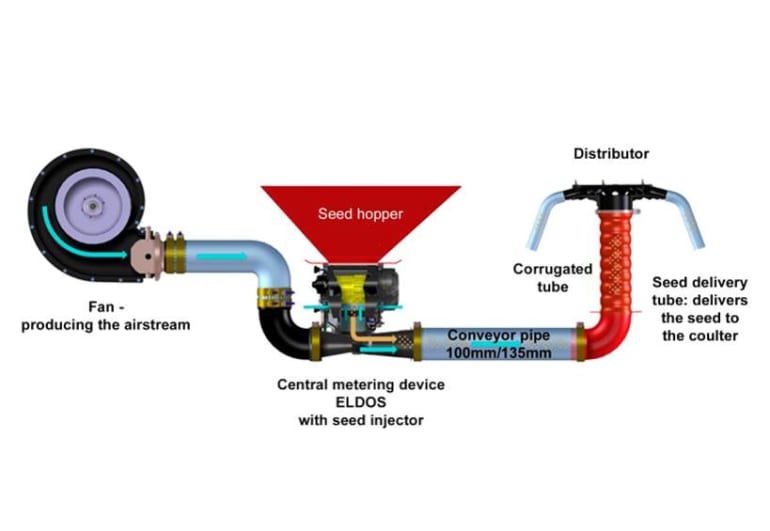

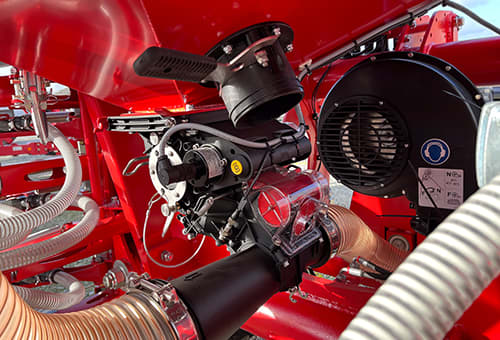

- The metering device ELDOS accurately measures the required volume of seed by the distinctive rotor and discharges it into the seed injector where is is mixed with the air stream and then conveyed through the diffusor tube and the seed delivery hoses to the coulters.

- The distribution head is mounted in a protected position inside the seed hopper.

- ELDOS is electric driven by e-bas and e-com, the e-com edition is fully ISOBUS compatible, e-bas works as stand alone controlled system.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Five standard rotors are delivered: for fine and large seeds or fertiliser.

- The exchange of the rotors is quickly and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

- The CX-II disc coulter from Kverneland not only guarantees smoother running but also exact seed placement.

- The flatter cutting angle of only 5.4° of the steel disc requires less pulling power to reach a constant seeding depth of up to 6cm.

- Due to the combination of the steel disc with a diameter of 325mm and the flexible plastic disc, there is no need for independent scrapers, saving the cost for expensive wearing parts. In addition the coulter is completely maintenance-free!

- Up to 50kg coulter pressure can be achieved by a pre-loaded spring. Safe operation is ensured when working with high working speeds and high quantities of plant residues on the soil surface.

- An inter-row coulter spacing of 445mm for maximum clearance and the following press wheel (standard equipment) ensure an optimum seed/soil contact in all conditions.

- The press wheels can be set in fixed, floating of lifted position in order to be able to adapt quickly to changing weather, soil or working conditions.

- The CX-II coulter is also available as light edition without press wheel which reduces the weight and length of the coulterbar. This will allow to operate the seeding combination also with lower lifting capacity of the tractor.

- The drill can be ordered with two different row spacings of 12.5cm or 25.0cm according to individual farming systems.

- The CX II coulters are clamped in staggered position over 2 rows by short and longer brackets.

- More clearance means different seed density and micro climate in the crop.

Choice of sowing distance

Sowing distance 12.5cm

- Best distribution for high seed rates

- Rows close quickly

- Reduced weed pressure

- Efficient use of nutrients, water and sun

Sowing distance 25cm

- Optimised micro climate reduces fungal infestation

- Less seeds needed per m² with new type of seeds (hybrid)

- Saving on water resources

- Reduced pulling force requested

- Better clearance in wet conditions

Kverneland Sync – The Implement Gateway

Always Connected – Easy and Direct

With Kverneland Sync, your seeder is continuously connected to Kverneland’s online services. Designed for efficiency and ease, Kverneland Sync represents a significant advancement in agricultural connectivity and productivity. Seamlessly integrate the ISOBUS seed drill Satio F e-com model with digital tools, empowering you to maximise profitability, growth, and success through real-time data analysis and performance measurement on working speed and seeds/m².

Remote Service – Minimize Downtime

Kverneland Sync offers remote diagnostics, allowing technicians to quickly analyze and address electronic issues on your seeder from a distance via the Kverneland ServiceCentre. This feature helps to minimize downtime in the event of a breakdown. See how it works: Always connected

Task Management – Enhance Reporting and Transparency

Kverneland Sync provides all relevant data in IsoMatch FarmCentre, our integrated farm management platform, enabling real-time tracking, performance measurement, and secure data storage. This is especially useful for machine cooperatives, streamlining logistics and invoicing. Additionally, Kverneland Sync enables geofencing to help protect your seeder against theft, with an accumulator that allows you to locate your seeder even when it’s not connected to a tractor.

The Satio F is available as e-bas and e-com model. Both models are equipped with the electric ELDOS metering device. The Satio F e-bas is not ISOBUS compatible and the electronic control is ensured by the Focus 3 terminal. The Satio F e-com model on the other hand is fully ISOBUS controlled and can be steered by the Kverneland Tellus 700, the Tellus 1200, or any other terminal.

Focus 3

Focus 3 is the terminal steering the e-bas system which features hopper low level sensor, various tramline systems, information about hectare, km/h, monitoring of fan speed, pre-emergence marker, seed rate adjustments. Focus 3 is not ISOBUS compatible.

Tellus 700

Single Screen, Multiple Options

Tellus 700 simplifies precision farming with smart features, custom mapping, and a user-friendly design. With ISOBUS compatibility and flexible packages, it boosts in-field efficiency and control.

Tellus 1200

Multiple Screens, Even more Options

Tellus 1200 the 12-inch universal Terminal offers intelligent hopper monitoring and precise variable rate application for fertiliser and seed. With an intueitive interface, multi-screen functionality, and GEOCONTROL compatibility, it delivers smart, all-in-one control beyond standard tractor systems.

IsoMatch FarmCentre

The best overview in farm management

The IsoMatch FarmCentre is a cloud-based farm management tool that works seamlessly with Tellus 700 and Tellus 1200 terminals. It allows you to monitor the machine activity, send tasks remotely to the terminal, and access real-time data and job reports – anytime, anywhere for smarter, more efficient farming.

Technical specifications

Technical specifications

Download brochure| Maschine type | Kverneland Satio 1050 F | Kverneland Satio 1060 F | |

|---|---|---|---|

| Frame | mounted foldable | mounted foldable | |

| Working width (m) | 5.0 | 6.0 | |

| Transport width (m) | 3.0 | 3.0 | |

| Hopper capacity (l) | 1700 | 1700 | |

| Quick emptying chute | Standard | Standard | |

| Low level sensor | Standard | Standard | |

| Linkage top | CAT II / CAT III | CAT II / CAT III | |

| Linkage low | CAT II / CAT III N / CAT III | CAT II / CAT III N / CAT III | |

| Wheel type | 26x12.00 | 26x12.00 | |

| Drive 1000 rpm | Option | Option | |

| Drive 540 rpm | Option | Option | |

| Hydraulic fan drive | Standard | Standard | |

| ELDOS electric driven metering device (no.) | Standard (1) | Standard (1) | |

| Radar speed sensor | Standard | Standard | |

| Micro metering | Standard | Standard | |

| e-bas electronic (Focus 3) | Standard | Standard | |

| e-com electronic (IsoMatch Tellus Pro/Tellus GO+) | Option | Standard | |

| Metering device control | Standard | Standard | |

| Seed rate adjustment | Standard | Standard | |

| Seed quantity (min. - max.) | 1 - 400kg/ha | 1 - 400kg/ha | |

| Shut-off valves for tramlines | Option | Option | |

| Electric half-width shut-off | Option | Option | |

| Pre-emergence marker | Option | Option | |

| No. of coulters 12.5cm distance (no.) | Standard (40) | Standard (48) | |

| No. of coulters 25cm distance (no.) | Standard (20) | Standard (24) | |

| CX-II coulter incl. press wheel | Standard | Standard | |

| CX-II coulter special disc shape without press wheel | Option | Option | |

| CX-II coulter disc Ø (mm) | 325 | 325 | |

| Press wheel Ø (mm) | 250 x 42 | 250 x 42 | |

| Coulter pressure CX-II disc coulter (kg) | 5 - 50 | 5 - 50 | |

| Mechanic coulter pressure adjustment by crank | Standard | Standard | |

| Hydraulic coulter pressure adjustment | Option | Option | |

| Mechanic central seed depth setting | Standard | Standard | |

| S-tine following harrow (10mm) | Option | Option | |

| Track eradicator | Standard | Standard | |

| Toolbox and calibration set | Standard | Standard | |

| Hydr. folding track marker with notched disc | Option | Option | |

| Loading step / Platform | Standard | Standard | |

| LED working lights | Option | Option | |

| Road light kit | Option | Option | |

| Oil charge hydr. fan 4400 U/min (l/min) | 30 | 30 | |

| Min. power requirement (HP/kW) | 122/90 | 146/108 | |

| Weight (kg) with coulters | 1370 - 2160 | 1450 - 2350 |

Technical specifications

Technical specifications

Download brochureModel |

Satio 1050 F |

Satio 1060 F |

Frame |

mounted foldable |

mounted foldable |

Working width (m) |

5.0 |

6.0 |

Transport width (m) |

3.0 |

3.0 |

Hopper capacity (l) |

1700 |

1700 |

ELDOS electric driven metering device (N°) |

Standard (1) |

Standard (1) |

N° of coulters 12.5cm distance (N°) |

40 |

48 |

N° of coulters 25.0cm distance (N°) |

20 |

24 |

Min. power requirement (HP/kW) |

122/90 |

146/108 |

Weight (kg) with coulters |

1370 - 2160 |

1450 - 2350 |