Kverneland 2501 S VARIOMAT

Plough | Reversible plough

From transport to perfect furrows in a record time

ISOBUS mounted reversible plough New Generation of Ploughs

The advantages of this Reversible plough

- FURROWcontrol with any ISOBUS screens

- Safe transport: optional Trailer Transport Solution

- Aero-profile high legs for best soil flow performance

- Quick central adjustments of skimmers

- All settings from the tractor cabin

Description

The Kverneland 2501 S i-Plough is the ISOBUS mounted reversible model ideal for modern farming. Recommended for tractors up to 280hp (206kW), the Auto-reset system enables ploughing in any soil conditions. 10 innovations improve your working life. Define any relevant plough settings from the tractor cabin: safe and trouble free connecting; automatic sequences to ensure a safe transport (TTS); easy marking for "non-square" fields and for nice ins and outs; any relevant ploughing adjustments with any ISOBUS screens. The FURROWcontrol RTK/DGP function enables easy straight furrows following a defined A-B line. These non proprietary solutions are clearly displayed on ISOBUS screens. Smart: finger tips adjustments.

Highlights

- FURROWcontrol with any Isobus screens

- Safe transport: Kverneland Trailer Transport Solution (optional: TTS)

- Aero-profile high legs for best soil flow performance

- Quick central adjustments of skimmers for the perfect ploughing

- Unique memory system that maintain desired furrow width settings after the reversing cycle

- Hydraulic front furrow adjustment

- Efficient re-consolidation in one pass: Packomat, Kverneland packers and packer arm compatible

Features

Features

Stepless Vari-width® system for infinite adjustments of working width. Kverneland’s world patented system is available either with hydraulic or mechanical furrow adjustments.

Benefits:

- Easy variation of ploughing capacity

- Perfect match at all time between tractor capacity, implement and soil conditions

- Time saving: up to 30% more capacity

- Cost saving: up to 18% reduction in fuel consumption in relation with increased ploughing capacity

- Better work: plough up to the hedges, fences, trees and ditches

- Minimum wear: unique non-wearing linkage joint between the beams and the mainframe section

- Perfect line of pull at all time. Kverneland’s Vari-width offers the correct parallel linkage along the whole plough. Therefore, lower draft requirement, minimum wear and tear.

Your Always Connected i-Plough

With Kverneland Sync, your i-Plough is continuously connected to Kverneland’s online services. Designed for user convenience and efficiency, Kverneland Sync ensures seamless data transfer between your i-Plough and the IsoMatch FarmCentre and Kverneland ServiceCentre platforms, allowing for optimal machine management and performance tracking.

Remote Diagnostics – Minimizing Downtime

Using Kverneland Sync, remote diagnostics are easily handled, enabling technicians to swiftly analyze and resolve electronic issues on your i-Plough from a distance via the Kverneland ServiceCentre. This significantly reduces machine downtime in the event of any breakdowns, ensuring your i-Plough is back in the field quickly.

Task Management – Enhancing Reporting and Efficiency

Kverneland Sync allows all key informations from your i-Plough to be easily accessed in IsoMatch FarmCentre, Kverneland’s integrated farm management platform. This feature offers real-time tracking, detailed performance analysis, and secure data storage—ideal for improving logistics, reporting, and invoicing when collaborating with farming cooperatives.

Geofencing & Enhanced Security

The i-Plough benefits from advanced security features, including geofencing through Kverneland Sync. Even when your plough is not connected to a tractor, the long lasting battery ensures that you can still locate it, protecting your valuable equipment from theft.

Excellent Ploughing Quality

They are renowned all over the world for their:

- excellent ploughing quality

- outstanding wear resistance

- low draft requirements

Bodies of a unique steel.

Kverneland Technology: 12 hours carburising heat treatment process for:

- optimum wear resistance (sharp as a diamond)

- the necessary flexibility to absorb impacts

Body No. 8 – “Universal body”

for light to heavy soils

good trash burial

easy pulling

Depth: 15 to 30 cm (6 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 9 – “Deep Universal body”

for heavier soils and deeper ploughing

well turned and packed furrows

easy pulling

Depth: 15 to 35 cm (6 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 28 – “Wide tyre body”

suits all soils; even heavier soils than body 8

very wide empty furrow for tractor wheels up to 710 mm

good turning and well packed

easy pulling

suitable for Depth: 12 to 30 cm ( 5 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 30 – “Finger body”

for sticky-stony soil and abrasive soils

good work in heavier soils

best crumbling effect

wide furrow bottom,

Depth: 20 to 35 cm (8 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 34 – Plastic mouldboard

Long and slim shape (similar to body 28)

For soils with high humus content without stones

Advised for tactors with large tyres

Easy pulling

Working depth: 12-35cm

Working width: 30-55cm

Landside / mouldboard: 40 degree

Body No. 38

universal body – easy to pull

for any soil conditions

recommended for tractors with large tyres

from deep to shallow ploughing

perfect turning of the furrow slice

working depth: 12-35 cm

working width: 30-55 cm

landside / mouldboard: 40°

Kverneland Heat Treatment Technology:

- more than 140 years of experience

- steels that withstand the toughest of conditions

- best robustness/weight ratio on the market

- for equivalent robustness, competitors would add more steel and therefore more weight, quicker wear, dissappointing ploughing results

Kverneland Steels:

- Benefits from less weight:

easier to pull/lower fuel consumption/lower lift requirement/reduced wear and stress for the tractor/more economical … - Benefits from more resistance:

minimum breakage/less maintenance/lower rotation for wearing parts/time saving/highest 2nd hand plough value/longer life for the plough/more economical…

Problems always happen when the plough is being used, when the work must be done!

A Kverneland plough is a peace mind!

More info: Kverneland Technology

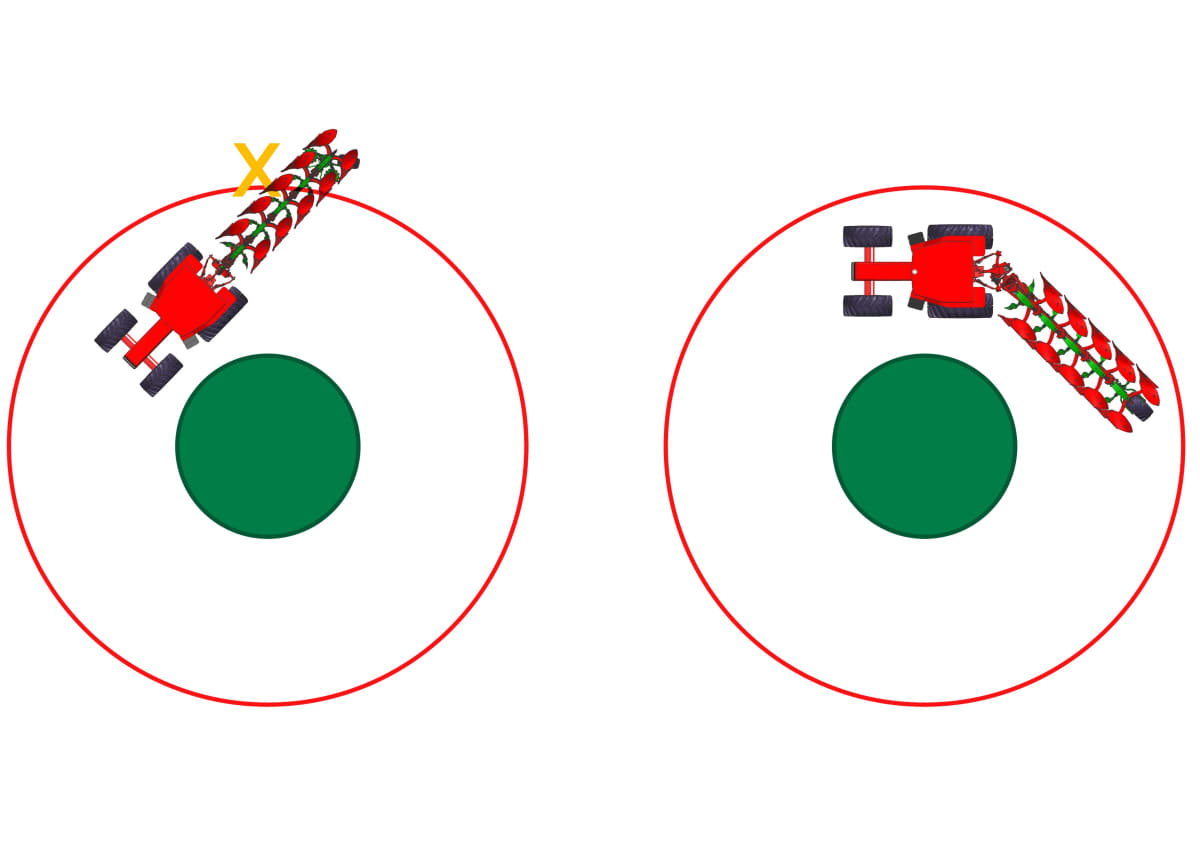

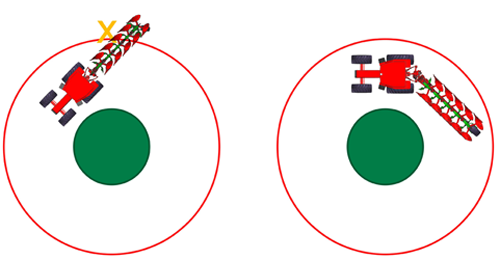

Kverneland “TTS” (Trailer Transport Solution)

- The plough behaves like a trailer. Turnable cross shaft max. 45° mutual offset during transport.

- Safe: maximum security for anything/anyone around and for the driver. No tilting out when driving in curves.

- Easy conversion from transport to ploughing.

- The Kverneland TTS is an option

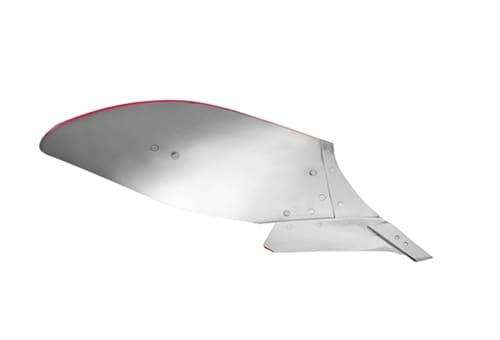

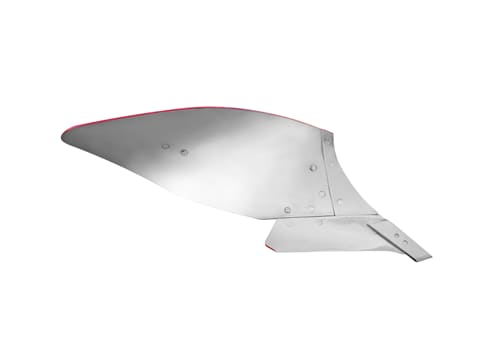

Aero-profile legs

- Special design for best soil flow.

- 80 cm leg height to prevent potential blockage in heavy residues, manure, cover crops or when ploughing deeper.

- Robust legs: pre-shaped components limiting weldings.

- Low pulling requirement and hence fuel consumption thanks to low weight hollow legs.

Auto-reset system

- Unrivalled Kverneland mechanical leaf spring system for Non-stop ploughing.

- No Maintenance.

- Legs, plough and tractor lives are protected and lengthened.

- Quality ploughing: legs release independently one from another and come back to the correct position.

- Easy adjustment of releasing forces: unscrew 2 bolts to add or remove springs.

Leaf springs |

Release Pressure kN |

Standard pack: 6 leaf springs |

11,2 |

HD pack: 7 leaf springs |

12,7 |

XHD pack: 8 leaf springs |

14,4 |

Double pack: 6+4 leaf spring |

16,9 |

Smart skimmers adjustment

- Unique: central adjustment of skimmers working depth.

- Quick operations: right and left skimmers adjust simultaneously.

- High ploughing performance: the correct adjustment of skimmers contribute to a quality ploughing.

- Disc coulters also available: plain or notched (18”/45cm or 20”/50cm)

Importance of heat treatment

- The frame is an essential part of the plough construction. For Kverneland quality standards, a non heat treated part is a weak part!

- Kverneland frames are heat treated by induction twice. The temperature transfer to the steel is closely monitored. The frame gains 3 times as much strength. This unique Kverneland induction processes provides robustness and flexibility while ensuring an outstanding durability.

Stronger but not heavier

- For the equivalent Kverneland robustness, competitors would use more steel in thickness or in dimensions, therefore producing a heavier frame.

- Heavier frame impacts negatively pulling forces, wearing of parts, lifting capacities, tractor life time, and fuel consumption.

Long lasting

- Weldings are also a critical weakness for a plough frame. Kverneland frames are supplied as one sole part!

Precision Farming

Precision Farming

When deciding what equipment to purchase, it is not always easy to find the optimal solution in the broad market offering of today. Technology is developing fast and tractors and implements are more and more equipped with high tech electronics. We understand this complexity and are committed to provide you with easy farming solutions. Therefore these cost-efficient ISOBUS Universal Terminals, IsoMatch Tellus PRO and IsoMatch Tellus GO+ are made for easy machine control and efficient farming.

With its advanced hardware and software features, the IsoMatch Tellus PRO provides the optimal precision farming solution for an all-in-one control system inside your tractor cab.

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything a farmer needs to get the maximum out of his machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives the farmer the opportunity to view and control two machines and processes simultaneously.

Work easy. Be in control.

IsoMatch Tellus GO+ is especially developed for controlling the machine in a simple way. The farmer is in full control of the machine in exactly the way he wants. Easy set up the machine with the soft keys via the 7-inch touch screen. And, optimal control while driving, just use the hard keys and rotary switch. Controlling the implement has never been so easy.

This can be you your first step into Precision Farming

IsoMatch Tellus GO+ makes it easy to control any ISOBUS machine from your tractor cab. IsoMatch GEOCONTROL enables you to achieve higher yields, lower costs and do your work with less hassle. This licence key is divided in two parts, Section Control and Variable Rate Control, which are available from the IsoMatch Shop. Now you can buy the specific functionality that you need.

Technical specifications

Technical specifications

Download brochure| Model | 2501S i-Plough® Variomat | 2501S i-Plough® Variomat | |

|---|---|---|---|

| Interbody clearance cm | 85 | 100 | |

| Head- stock | Nº 250 | Nº 250 | |

| Type of beam | Autom. | Autom. | |

| Working width cm | 30-60 | 30-60 | |

| Underbeam clearance cm | 80 | 80 | |

| No. of furrows | 4-6 | 4-6 | |

| Weight (kg), 3 furrows | – | – | |

| Weight (kg), 4 furrows | 1950 | 2010 | |

| Weight (kg), 5 furrows | 2280 | 2355 | |

| Weight (kg), 6 furrows | 2650 | 2810 | |

| Lift requirement (kg), 3 furrows | – | – | |

| Lift requirement (kg), 4 furrows | 5100 | 5350 | |

| Lift requirement (kg), 5 furrows | 6800 | 7050 | |

| Lift requirement (kg), 6 furrows | 8800 | 9200 |

Technical specifications

Technical specifications

Download brochureModel |

Interbody clearance cm |

Head stock |

Type of beam |

Working width cm |

Under beam clearance |

No of furrows |

2501 S i-Plough Variomat |

85/100 |

250 |

Auto-reset |

30 - 60 |

80 |

4 - 6 |