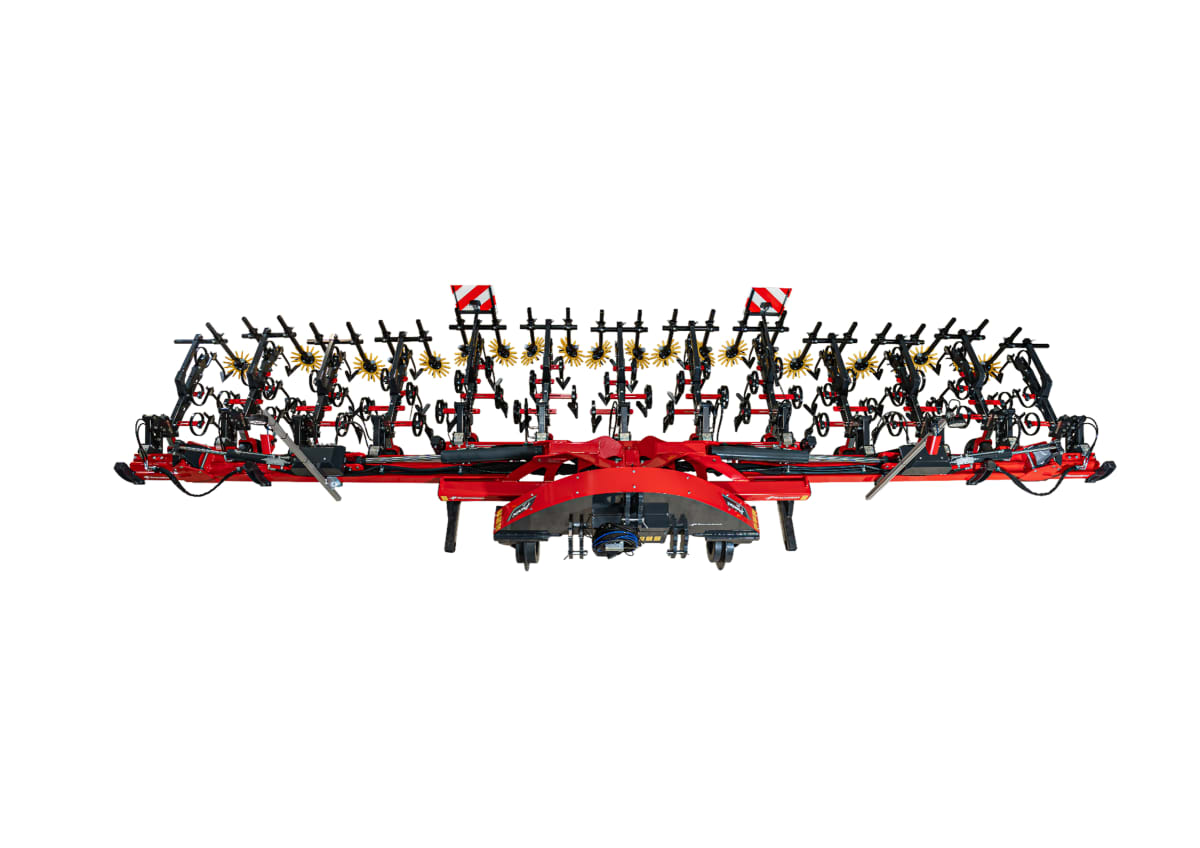

Kverneland Onyx 4000 F

Weeder | Inter-row cultivator

Efficient weed control is a prerequisite for healthy plant growth as the basis for yield, profit and safe food production

Inter-row cultivator for mechanical weed control in row crops and cereals

The advantages of this Inter-row cultivator

- Strength and rigidity for accurate straight lines

- Each element is working independently

- Even depth control over the entire working width

- Flexibility and high performance

- Prepared for challenging conditions

Description

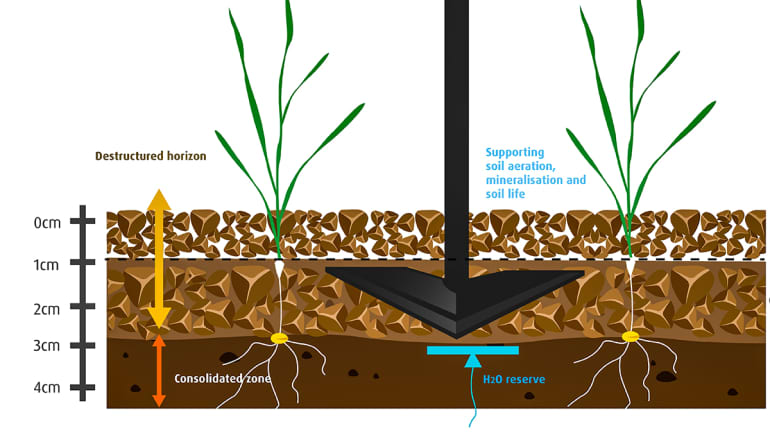

The Kverneland Onyx cuts the roots of the weeds as closely to the plants as possible without damaging the crops by ensuring the straight line within the row. In addition, by cracking the capped surface on certain soils after rain, the Onyx promotes the seed emergence and restores the water and air flow, stimulating physico-chemical reactions and soil life.

By creating a isulating layer stopping the capillary rising of water to the surface, the Onyx also increases the water reserve.

For different crops and row widths, the Onyx can be quickly adapted is possible. Also the working width is adjustable to meet the requirements of various field and farm sizes. Individual rows can be switched on and off. An even depth and pressure control is ensured over the entire working width.

Highlights

- Strength and rigidity for accurate straight lines

- Row width of the tools and shares are quickly adapted to the various crops

- Each element is working independently

- Even depth control over the entire working width

- Flexibility and high performance for various field and farm sizes

- Prepared for challenging conditions by extra pressure control

- Low lifting requirement

- Increase mineralization

Features

Features

The Kverneland inter-row cultivator Onyx has been designed to easily achieve an accurate and consistent result in field. The weeding efficiency is achieved even at high working speed, with or without guidance system depending on the row width, starting from 12.5cm for cereals. The sturdy design of the ONYX ensures a long lasting accuracy and lifetime.

Selective weed control

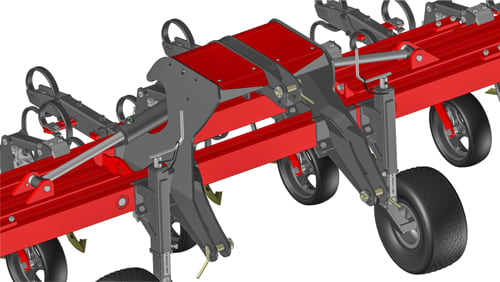

The inter-row cultivator, ONYX offers a maximum in rigidity and adaptability. It is quickly prepared for larger fields by extensions. The parallelograms and working tools are rigid and rule out any wear and play. Stable and high accuracy are ensured even down to 12.5cm row width. The exclusive X-CONTROL pressure adjustment (max. 120kg) with a preloaded spring system transfers the load from the frame to the tines. There is a wide range of shares available in Carbide quality and a large variety of accessories in order to meet all sorts of conditions.

The large diameter of gauge wheel avoids any bulldozing effect. Each element is working independently. Fitted with GEOCONTROL, up to 13 sections are automatically lifted by ISOBUS.

Stimulating physico-chemical reactions and soil life

The shallow tillage at 2cm by the Kverneland Onyx improves aeration of the soil as a prerequisite to physicochemical reactions (humification, mineralisation of organic nitrogen). The crops will benefit from the plus of nutrients available with positive impact on the yield. By disrupting the topsoil’s upper layer, the harrow restores the fluids, water, air, vertical flows and stimulates physicochemical reactions, mineralisation and soil life.

Protecting soil moisture

By the flat-bed weeding, the Kverneland Onyx creates an isolating layer to stop the capillary rising of water to the surface, protecting the soil moisture within the seed layer. “One pass of weeding is like two times watering,” says a proverb. With view to the climate change, this is of major importance in dry areas and a general benefit for the crop’s start and growth.

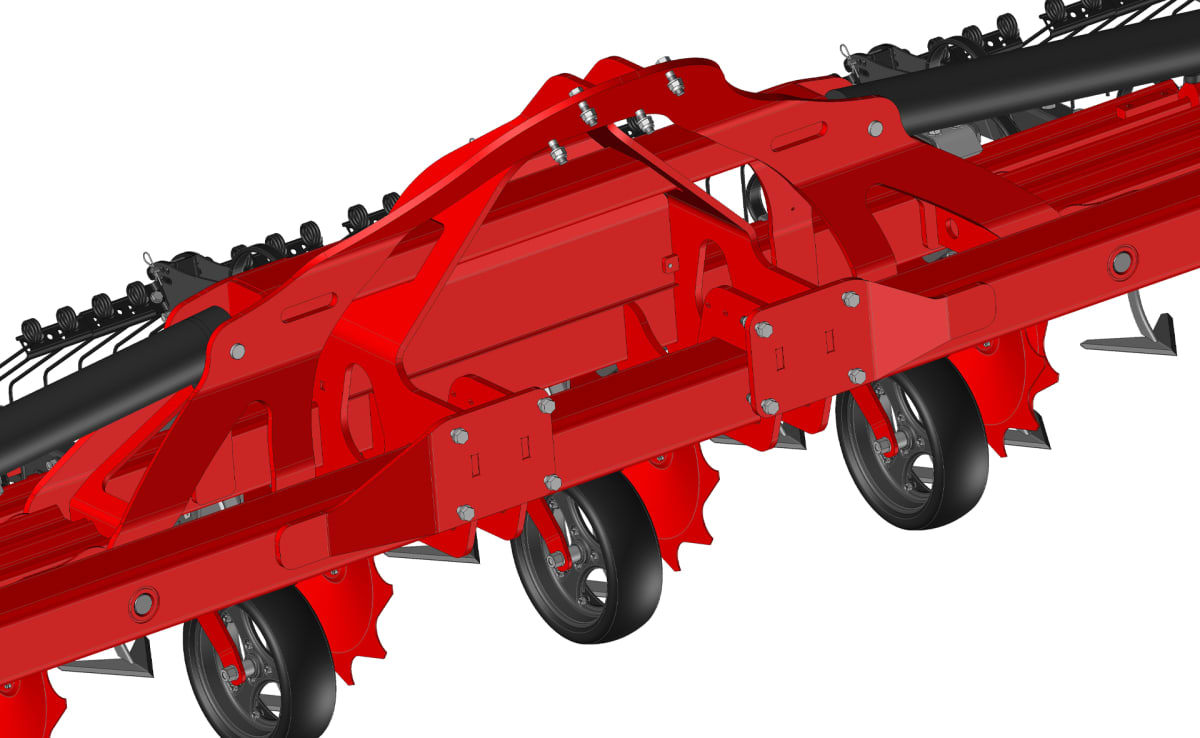

The Kverneland inter-row cultivator, ONYX with the Double-H shaped frame offers a maximum in rigidity and adaptability. Ready to be upgraded by extensions, the frame is quickly prepared for larger fields and farms.

Double-H frame

The Double-H shaped beam offers a maximal sturdiness and allows a firm fixation of the weeding elements. In addition, it increases the penetration force by transferring the load to the tines and shares. Its sturdy concept provides safe transport on roads. The ONYX is equipped with the standard version of Cat. II linkage. The spacing between the elements can be simple changed due to the universal frame system (UF System). Hydraulic and electrical interfaces are simple to connect with the push pull system and are easily accessible.

Three models

The product group of the Kverneland ONYX proposes three models, mounted and foldable: standard, compact and integrated according to their type of linkages. Each frame can be upgraded with frame extensions with different tube lengths of twice 120, 800 or 1450mm to obtain a width on the compact folding version of up to 7.70m and the wide folding version of up to 12.10m.

Pneumatic gauge wheel

Either two or four additional gauge wheels positioned in front of the middle frame bar or/and at the outer extensions ensure an optimal following of the ground contour, give more stability and a constant depth control especially with larger working widths. Depth setting is done mechanically via a clamp lockable crank on all wheels. A scale indicates the depth for precise adjustment.

Parking legs

Original parking legs are delivered as standard for storage of the machine. The parking legs allow an easy and safe coupling and uncoupling to the tractor.

The Kverneland Onyx can be equipped with different tines and shares to meet all requirements and conditions. The aim is to protect the plant while suffocate and scalping the weeds as closely to the crops as possible, maintaining soil moisture by shallow tillage and moving the soil as less as necessary.

The height adjustable straight A-tine without vibration effect with either A-shaped flatbed weeding or L-shape lateral adjustable shares ensure shallow tillage with precise scalping of the weed and can be used in all crops. The L-shares which are available in left and right version limits soil projections on young crops and are mounted on tines positioned close to the seeding row. Several share widths and assembly options are available for row widths from 12.5 to 80cm.

Alternatively a semi-curved SC-tine with duck foot share (DF-share) or half duck foot share (HDF-share) allow deeper and more intensive soil tillage due to a higher vibrating effect. Optionally a ridger share positioned on the tine which is the closest to the sowing row of the crop and guides the soil flow directly to the sowing line. It is particularly suitable for developed higher crop vegetation to avoid suffocation of crop but not of the weed in the line.

The Kverneland Onyx features high quality with long lasting components. Thus, the Onyx inter-row cultivator maintains its reliable and accurate performance even under most demanding conditions.

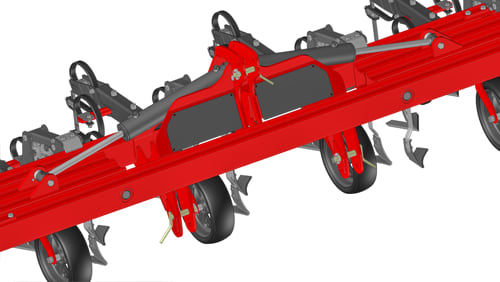

X-CONTROL parallelogram

The parallelograms are equipped with conical pins and hardened polymer bushings which do not float and rule out any wear and play. This provides excellent stability and high accuracy from 12.5cm up to 80cm row width. The constant depth control over the entire working width ensures best results in row crops and cereals. A hydraulic or mechanical parallelogram version is available. They are adjustable in both depth and pressure.

Both versions are equipped with a preloaded double springs system, the exclusive X-CONTROL. This pre-loaded, spring-based system provides an individual load transfer from the frame to the tines of max. 120kg and eliminates any play or bouncing of the element. This gives the tines extra stability. The working depth stays absolutely constant, which is essential for the effectiveness of flatbed weeding at shallow depths without mixing the horizons.

Kverneland always focuses on safe operation and user comfort. With all the adjustments being done without the need of special tools, a lot of precious time is saved! Adjusting the Kverneland ONYX is easily done with only one spanner (22mm). A wide range of configuration possibilities are available to meet all kind of requirements and conditions and to achieve best results.

1. With the hydraulic linkage of the tractor the implement is adjusted horizontally aligned with the complete frame.

2. The working depth is set-up by the gauge wheels of each element. The pressure adjustment at the parallelogram is regulated via a pre-loaded spring which transfers the weight to the tines and shares. Scales indicates the exact adjustment.

3. For the precise row width each tine can be adjusted to the side with sliding elements.

4. Finally, each additional accessory e.g. finger weeder, side plates, finger harrow, discs etc. or the feeler and camera must be fine-tuned to the field conditions and growth level.

5. The spring protection of the weeding element supports the penetration and ensures a constant working depth

Optimize Your Farm Operations with ISOBUS Terminals and Variable Rate Control

When equipped with ISOBUS technology, the Inter-row cultivator Onyx is fully configurable and automated via the terminal Tellus 700 or Tellus 1200. It will relieve the driver’s stress. By automatically dodging some predefined areas providing a true precision operation, even with poor visibility or high vegetation.

It offers everything you need to get the most out of your machines and crops, while reducing costs on fertiliser and chemicals through automatic section control and variable rate control.

With the goal of maximizing your machinery’s full potential, Tellus terminals can simultaneously manage multiple ISOBUS implements with several variable rate maps.

This combined functionality is key to saving both time and money in modern agriculture — which is why more and more farmers are using inter-row cultivators in combination with other systems. The setup can include an iXtra Life front tank for liquid fertilizing or herbicide application, or a f-drill front hopper for side-dressing fertilization.

In such situations, Tellus terminals are the ideal tools to optimise input savings. They manage both ISOBUS implements, control section operation for each, and apply variable rate maps to ensure precise product distribution.

Tellus 700 - Single Screen

Single Screen with multiple Options - Tellus 700 simplifies precision farming with smart features, custom mapping, and a user-friendly design. With ISOBUS compatibility and flexible packages, it boosts in-field efficiency and control.

Tellus 1200 - Multiple Screens

Multiple Screens with extended range of Options - Tellus 1200, the 12-inch universal Terminal offers intelligent hopper monitoring and precise variable rate application for fertiliser and seed. With an intuitive interface, multi-screen functionality, and GEOCONTROL compatibility, it delivers smart, all-in-one control beyond standard tractor systems.

IsoMatch FarmCentre

The best overview in farm management - The IsoMatch FarmCentre is a cloud-based farm management tool that works seamlessly with Tellus 700 and Tellus 1200 terminals. It allows you to monitor machine activity, send tasks remotely to the terminal, and access real-time data and job reports – anytime, anywhere for smarter, more efficient farming.

Technical specifications

Technical specifications

Download brochure| Model | Onyx 4081 F | Onyx 4092 F | Onyx 40121 F | Onyx 4081 FXL | Onyx 4092 FXL | Onyx 40121 FXL | |

|---|---|---|---|---|---|---|---|

| Mounted frame | fold | fold | fold | fold | fold | fold | |

| Basic frame (m) | 8.10 | 8.10 | 8.10 | 8.10 | 8.10 | 8.10 | |

| Extensions (m) | - | 2 x 0.55 | 2 x 0.55 & 2 x 1.45 | - | 2 x 0.55 | 2 x 0.55 & 2 x 1.45 | |

| Frame width (m) | 8.10 | 9.20 | 12.10 | 8.10 | 9.20 | 12.10 | |

| Transport width (m)*** | 3.47 | 3.47 | 3.47 | 4.60* | 4.60* | 4.60* | |

| Linkage | Integrated Lynx 3000 | Integrated Lynx 3000 | Integrated Lynx 3000 | Integrated Lynx 3000 | Integrated Lynx 3000 | Integrated Lynx 3000 | |

| Gauge wheels 18.5x8.50-8 (no) | Option (2) | Option (2) | Standard (2) / Option (2) | Option (2) | Option (2) | Standard (2) / Option (2) | |

| Row spacings available (cm) | 12.5 - 15 - 16.6 - 20 - 25 - 30 - 37.5 - 40 -45 - 50 - 60 - 70 - 75 - 76.2 - 80 | 12.5 - 15 - 16.6 - 20 - 25 - 30 - 37.5 - 40 -45 - 50 - 60 - 70 - 75 - 76.2 - 80 | 12.5 - 15 - 16.6 - 20 - 25 - 30 - 37.5 - 40 -45 - 50 - 60 - 70 - 75 - 76.2 - 80 | 12.5 - 15 - 16.6 - 20 - 25 - 30 - 37.5 - 40 -45 - 50 - 60 - 70 - 75 - 76.2 - 80 | 12.5 - 15 - 16.6 - 20 - 25 - 30 - 37.5 - 40 -45 - 50 - 60 - 70 - 75 - 76.2 - 80 | 12.5 - 15 - 16.6 - 20 - 25 - 30 - 37.5 - 40 -45 - 50 - 60 - 70 - 75 - 76.2 - 80 | |

| Parallelograms | hydraulic | hydraulic | hydraulic | mechanical / Option hydraulic | mechanical / Option hydraulic | mechanical / Option hydraulic | |

| Finger Harrow | Option | Option | Option | Option | Option | Option | |

| Finger Harrow (410 x 7mm) | with 3 - 4 - 5 - 7 or 9 tines; multi-position system to adjust aggressiveness | with 3 - 4 - 5 - 7 or 9 tines; multi-position system to adjust aggressiveness | with 3 - 4 - 5 - 7 or 9 tines; multi-position system to adjust aggressiveness | with 3 - 4 - 5 - 7 or 9 tines; multi-position system to adjust aggressiveness | with 3 - 4 - 5 - 7 or 9 tines; multi-position system to adjust aggressiveness | with 3 - 4 - 5 - 7 or 9 tines; multi-position system to adjust aggressiveness | |

| Finger weeder | Option | Option | Option | Option | Option | Option | |

| Finger weeder (mm) | 250 - 290 - 370 | 250 - 290 - 370 | 250 - 290 - 370 | 250 - 290 - 370 | 250 - 290 - 370 | 250 - 290 - 370 | |

| Side discs | Option | Option | Option | Option | Option | Option | |

| Straight opening discs | Option | Option | Option | Option | Option | Option | |

| Ridger disc | Option | Option | Option | Option | Option | Option | |

| Side plates | Option | Option | Option | Option | Option | Option | |

| Ridger share | Option | Option | Option | Option | Option | Option | |

| Tines and share type | A-tine with A-share and/or L-share OR SC-tine with DF and HDF share** | A-tine with A-share and/or L-share OR SC-tine with DF and HDF share** | A-tine with A-share and/or L-share OR SC-tine with DF and HDF share** | A-tine with A-share and/or L-share OR SC-tine with DF and HDF share** | A-tine with A-share and/or L-share OR SC-tine with DF and HDF share** | A-tine with A-share and/or L-share OR SC-tine with DF and HDF share** | |

| Pilot control kit (man. steering) | Option | Option | Option | Option | Option | Option | |

| Weight for 50cm row spacing with finger harrow (kg) | 2095 | 2430 | 3405 | 2150 | 2430 | 3405 | |

| Heaviest model without accessories (kg) | 2230 | 2620 | 3250 | 2290 | 2620 | 3310 | |

| Min. HP requirement | 130 | 140 | 150 | 130 | 140 | 150 |

* With mechanical parallelogram in work position

** A-tine = adjustable straight tine; SC-tine = semi-curved vibrating tine; A-share= flat weeding share; L-share = lateral L-shape share; DF=duck foot share; HDF = half duck foot share left or right version

*** Transport width can be differnt due to configuration options, please ask your local dealer

Technical specifications

Technical specifications

Download brochureModel |

Onyx 2030 |

Onyx 2048 F |

Onyx 2064 F |

Onyx 2077 F |

Basic frame (m) |

2.84 rigid |

4.80 fold |

4.80 fold |

4.80 fold |

Extensions (m) |

2 x 0.12 |

- |

2 x 0.8 |

2 x 1.45 |

Frame width (m) |

2.84 / 3.08 |

4.80 |

6.40 |

7.70 |

Transport width (m)* |

3.08 |

2.84 |

2.84 |

2.84 |

Linkage |

Standard CAT. II |

|||

Row spacings available (cm) |

45 - 50 - 60 - 70 - 75 - 76.2 - 80 |

|||

Tines and share type** |

A-tine with A-share and/or L-share OR SC-tine with DF and HDF share |

|||

Weight for 50cm row spacing with finger harrow (kg) |

763 |

1230 |

1565 |

1720 |

Min. HP requirement |

60 |

100 |

110 |

120 |

Model |

Onyx 3030 |

Onyx 3048 F |

Onyx 3064 F |

Onyx 3077 F |

Basic frame (m) |

2.84 rigid |

4.80 fold |

4.80 fold |

4.80 fold |

Extensions (m) |

2 x 0.12 |

- |

2 x 0.8 |

2 . 1.45 |

Frame width (m) |

2.84 / 3.08 |

4.80 |

6.40 |

7.70 |

Transport width (m)* |

3.08 |

2.84 |

2.84 |

2.84 |

Linkage |

Compact CAT. II |

|||

Row spacings available (cm) |

12.5 - 15 - 16.6 - 20 - 25 - 30 - 37.5 - 40 -45 - 50 - 60 - 70 - 75 - 76.2 - 80 |

|||

Tines and share type** |

A-tine with A-share and/or L-share OR SC-tine with DF and HDF share |

|||

Weight for 50cm row spacing (kg) |

700 |

1080 |

1425 |

1575 |

Min. HP requirement |

60 |

100 |

110 |

120 |

Model |

Onyx 4081 F |

Onyx 4092 F |

Onyx 40121 F |

Onyx 4081 FXL |

Onyx 4092 FXL |

Onyx 40121 FXL |

Basic frame (m) |

8.10 fold |

|||||

Extensions (m) |

- |

2 x 0.55 |

2 x 0.55 & 2 x 1.45 |

- |

2 x 0.55 |

2 x 0.55 & 2 x 1.45 |

Frame width (m) |

8.10 |

9.20 |

12.10 |

8.10 |

9.20 |

12.10 |

Transport width (m)* |

3.47 |

3.47 |

3.47 |

4.60 |

4.60 |

4.60 |

Linkage |

Integrated Lynx 3000 |

|||||

Row spacings available (cm) |

12.5 - 15 - 16.6 - 20 - 25 - 30 - 37.5 - 40 -45 - 50 - 60 - 70 - 75 - 76.2 - 80 |

|||||

Tines and share type** |

A-tine with A-share and/or L-share OR SC-tine with DF and HDF share |

|||||

Weight for 50cm row spacing (kg) |

2095 |

2430 |

3405 |

2150 |

2430 |

3405 |

Min. HP requirement |

130 |

140 |

150 |

130 |

140 |

150 |

* Transport width may differ according to configuration options

** A-tine = adjustable straight tine; SC-tine = semi-curved vibrating tine; A-share= flat weeding share; L-share = lateral L-shape share; DF=duck foot share; HDF = half duck foot share left or right version

* With mechanical parallelogram in work position

** A-tine = adjustable straight tine; SC-tine = semi-curved vibrating tine; A-share= flat weeding share; L-share = lateral L-shape share; DF=duck foot share; HDF = half duck foot share left or right version

*** Transport width can be differnt due to configuration options, please ask your local dealer