Easy settings for a peace of mind

The range of Kverneland new generation shear bolt ploughs is designed for professionals. It is the logical step forward after the successful launch of the new generation auto-reset ploughs (2019). This new range builds on the existing well known benefits in using Kverneland ploughs and goes beyond with some new relevant features.

4 plough models for tractors 250-380 Hp, named Kverneland 2300 B, 3300 B, 3400 B, 3500 B i-Plough.

Low draft Kverneland bodies, the correct pulling line at any time and the unequalled low cost of ownership are carried on this new range.

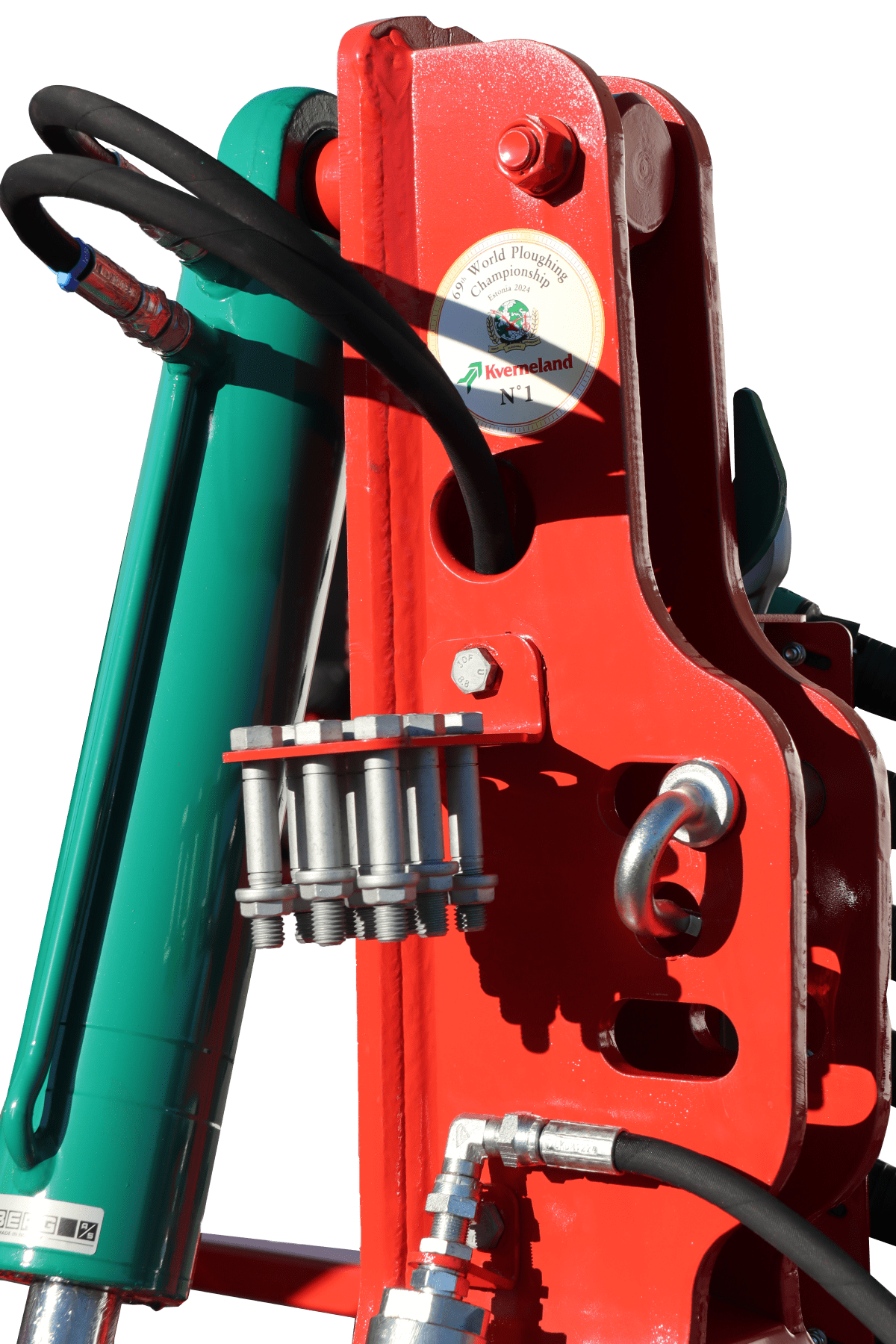

New shear bolt legs

The new shear bolt legs are stronger than ever. Their new design enables a shear cut of the bolts under a pressure as high as 5000 kg. No stretch of the bolt which could lead to a possible deformation of the leg under pressure. The new design ensures that the shear bolt can be instantly replaced in an easy manner which guarantees a consistent ploughing quality.

Smart, spare bolts are handily stored on the head stock.

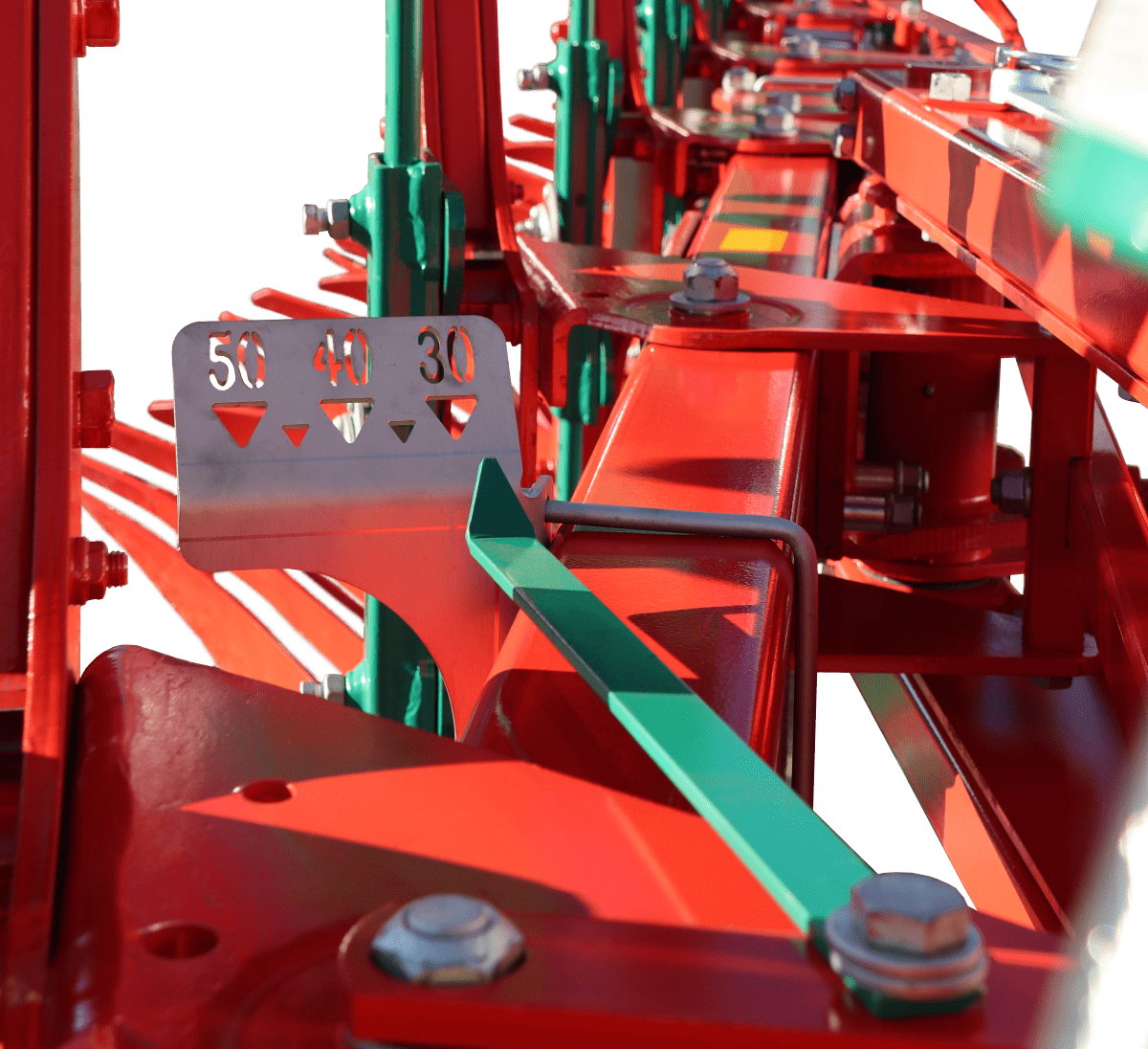

«4P» skimmers (4 Positions)

Every farmer knows that well adjusted skimmers make the ploughing results. Kverneland has developed the «4P» skimmers to enable ploughing in any soil conditions, residues, speed via easy adjustments. Adjusting the ploughing depth means changing the skimmers working depth accordingly. It is quickly done via the Patented centrally adjustable skimmer depth. Additionally, you have the possibility to change the angle of the skimmer in 3 different positions, to move the complete skimmer assembly either backward or forward and even laterally, more On-land, in a simple way.

These options will contribute to the perfect soil preparation.

Kverneland hydraulic wheels uniqueness

A new range of wheels is available for the Kverneland new generation shear bolt ploughs: rear and frame mounted wheels, mechanical and hydraulic. Keeping in mind that Kverneland aims at easing the working life of farmers, it is made easy to change the working depth. To keep the settings after reversal at headlands is unique.

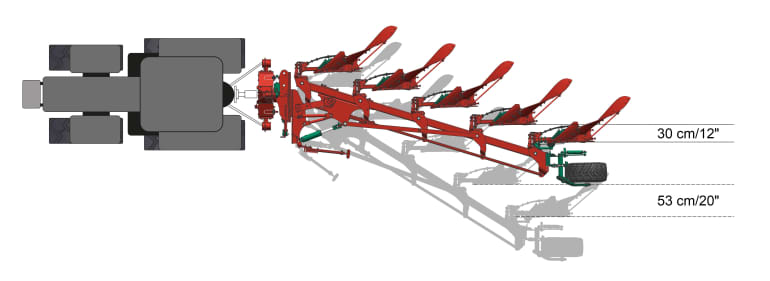

Trailer Transport Solution (TTS)

Kverneland is the inventor of the Trailer Transport Solution (TTS). It offers the possibility to maneuver safely in narrow passes or roundabouts. It also protects the head stock from unnecessarily stress during transport. The Kverneland plough behaves just like a trailer behind a tractor. The pivot point of tractor and implement combination is located in the middle. Therefore, there is no tilting out.

The TTS is available on the models Kverneland 3300 B Variomat, 3400 B Variomat and 3500 B Variomat i-Plough®.

Kverneland 3500 B i-Plough

When the same features apply to each model of this new range, the Kverneland 3500 B i-Plough® stands out with its Isobus functions. The most essential settings are done from the tractor cabin: highlight in this is that the driver can switch from In-furrow ploughing to On-land ploughing with one finger tip. Other functionalities like FURROWcontrol® for straight furrows following an A-B line, bring an extra level of performances and comfort. Likewise, the Kverneland Sync enables seamless data transfer for optimal machine management and performance tracking.

The Details That Counts

Hydraulic handles for effortless grab. Easily identifiable. Organised setting

Handily stored spare shear bolts

A very visible indicator of the working width