Optima F (SX)

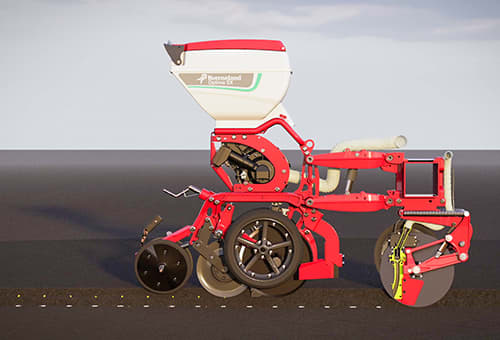

Seeder | Pneumatic precision drill

Kverneland Optima F for short set-up and high performance

Pneumatic precision drill with parallel-hydraulic folding frame for a large performance

The advantages of this Pneumatic precision drill

- Best manoeuvrability and unrestricted overview

- Universal pneumatic precision drill

- Utmost precision

- ISOBUS intelligence

- GEOCONTROL, GEOSEED and GEOFORCE

Description

The Kverneland Optima is the universal pneumatic precision drill for maize, sunflowers, field beans, unpelleted beet, pelleted beet, dwarf beans, soya beans, peas, and many other types of seeds. Within this product group, this folding model Optima F is fitted with SX high speed sowing units. The Optima F with a working width of 6m is quickly folded to transport position. The frame can be equipped with 8 rows for maize, 12 rows for the combined usage in sugar beet, maize, sunflowers or soya.

The micro-granule applicator, micro-drill, is available as an option. For the application of fertiliser, the Optima F can be combined with the front hopper f-drill, which is fitted with the ELDOS metering device and the appropriate distribution head for row fertilizing. In combination with iXtra LiFe, application of liquid fertiliser during seeding is possible. The Optima F is fully ISOBUS compatible and ready for GEOCONTROL, GEOSEED and GEOFORCE. Equipped with Kverneland Sync, the Optima F benefits from real-time data transfer to IsoMatch FarmCentre and Kverneland ServiceCentre for full control and documentation.

The Optima F can be equipped with the PUDAMA system to increase the efficiency in the use of mineral starter fertiliser in row crops. With the targeted fertiliser application by PUDAMA, the amount and location of the nutrients are precisely defined to where the roots of the grains can reach them and only as much as needed.

Modular Design for Maximum Flexibility

The Optima precision drill features a modular design. The basic element remains the same, but equipment can be customized to suit different soil types, farming systems, and individual requirements.

Kverneland Optima with SX high speed sowing unit - precise seed placement for every soil condition up to 18km/h

The Kverneland Optima precision planter with SX sowing unit is engineered to deliver accurate seed placement, ensuring maximum crop emergence and yield. Its advanced high speed sowing unit SX follow the ground contour perfectly, with optimum depth control. It carries out accurate seed singulation and precise seed placement up to 18km/h. The Optima SX high speed sowing unit is increasing performance and efficiency. Each sowing row is electrically powered by ISOBUS connection. An additional generator or other power sources are not required. The complete power supply and control is via ISOBUS.

Highlights

- Best manoeuvrability and unrestricted overview

- Utmost precision

- Versability in adjustment to seed type and soil conditions

- ISOBUS intelligence

- Saving seeds and fertiliser by precise and defined applicationwith GEOCONTROL and GEOSEED

- Utmost efficiency by automatic sowing depth and pressure control by GEOFORCE

- In combination with iXtra LiFe, application of liquid fertiliser during seeding is possible.

Features

Features

Up to 18km/h for utmost efficiency

- Optimum depth control due to the heavy basic weight of the sowing unit with the possibility to add additional pressure (up to 100kg) onto each individual sowing unit via spring-loaded system.

- Effective ground contour following due to the large depth control by open gauge wheels (⌀410mm, with 120mm)

- Precise seed placement by the small coulter which forms a clean furrow. Good placement, and seed covering is done by the smooth flexible intermediate press wheel and multi-adjustable V-press wheel.

Seeding heart – Optima SX

- With the pressurized seeding heart, the seeds are “shot” by an airstream of up to 70kph into the furrow. A smooth, flexible intermediate press wheel catches and protects the delicate seeds. Any negative impact such as vibration on the way between release point and soil contact are eliminated due to the high air stream.

- The seeds reach their perfect position in the soil. Each sowing row is electrically powered by ISOBUS connection. An additional generator or other power sources are not required. The complete power supply and control is via ISOBUS.

- Stable design, modular system, low maintenance costs, high degree of wear resistance and optimum depth placement.

- For fertiliser placement Kverneland supplies hoppers for different applications.

- The chain drive for metering can be adjusted from 106 to 390kg per hectare at a distance between rows of 75cm.

- The fertiliser applicator is driven centrally by an easily accessible side mounted gear box.

- Fertilising coulter, standard seeding with narrow coulter design and stable, reliable construction, coil spring protection from sideways forces

- Mulch seeding notched double-disc coulter for blockage-free and precise fertiliser placement by a Ø 350mm notched double-disc Coulter.

The Kverneland PUDAMA system solution

Fertilisation ensures the supply of nutrients to the crop, but over-fertilisation often has undesirable effect on the environment and the ecosystem of the land.

How to keep the balance?

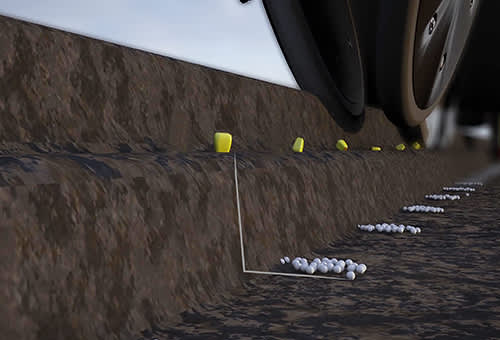

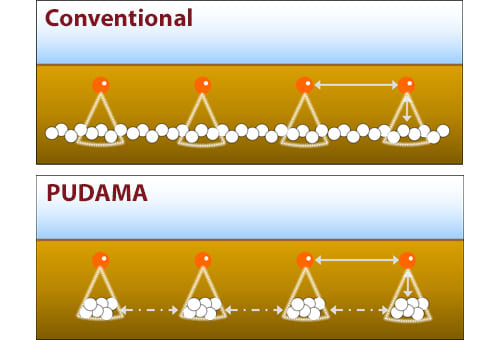

Conventional band application places a continuous band of fertiliser also between the plants, where the roots cannot reach it. This is the amount of fertiliser simply wasted and washed out.

Kverneland PUDAMA

With PUDAMA the amount and location of the fertiliser is precisely defined. The nutrients are only deposited where the roots of the grain can reach it and only as much as needed. Synchronised with the seed application at high speeds, a cloud of fertiliser is placed by an air stream below and sidewards to the seed during seeding process. Every seed has an optimal fertiliser depot at its disposal which is completely absorbed by the plants. In this way, loss and leaching is avoided and the production of fertiliser raw materials can also be reduced. In brief, PUDAMA is increasing the efficiency in the use of mineral starter fertiliser in maize – thus maintaining 100% yield whilst saving at least 25% starter fertiliser.

GEOCONTROL - Cost saving with immediate payback

Seeding with GPS and GEOCONTROL in combination with an electric driven precision drill is a major step towards precision and cost saving. These machines are all equipped with ISOBUS technology which with the help of the IsoMatch Tellus terminal, can be easily controlled.

Each electric driven seeding element, in combination with GPS and GEOCONTROL, is automatically switched on or off in exactly the right place, ensuring there is no overlap with any row that has already been seeded. This is especially handy in triangular fields, on curved or irregular shaped headlands.

GEOSEED - Precision at high end

GEOSEED is the precise synchronization of seed placement across the full working width of the machine. This ensures that seeds are distributed evenly, achieving an optimal pattern—either parallel or diamond-shaped—across the soil surface. The positive effects of this technology are far-reaching. By enhancing seed distribution, GEOSEED maximizes the efficient use of key resources such as nutrients, water, and sunlight, fostering optimal plant growth. Additionally, this uniform planting pattern helps reduce the risks of wind and water erosion, as the even distribution of plants improves soil structure and coverage, leading to better water retention and minimizing soil degradation.

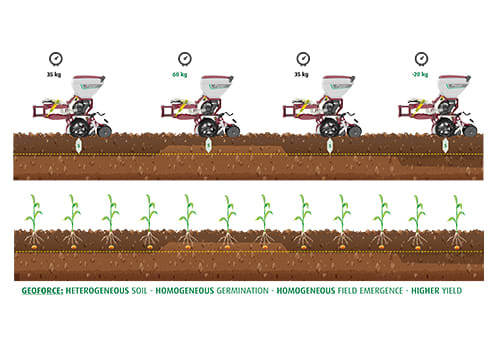

Due to varying soil conditions and working speeds, the force required to maintain a defined working depth will vary. Kverneland GEOFORCE is the automatically steered constant depth guidance on the go, independent from changing soil conditions, residues, weather and working speed. Perfectly precise seed placement at an even sowing depth is the pre-requisite for optimal field emergence, good harvest conditions, resulting in higher yields and best corn quality.

With the new GEOFORCE system, each individual Optima sowing row is automatically pressurized adjusting to changing soil conditions or forward speeds. The automatic, constant pressure control ensures optimal seed placement at an even seed horizon which results in uniform seed germination and field emergence. Especially smaller seeds like rape, which need a shallower sowing depth, benefit from the release option of GEOFORCE. In addition, the bulldozing effect or formation of dams in very light soil conditions are prevented.

The GEOFORCE system

Varying conditions are challenging as light soil requires less pressure to penetrate the soil by the cutting discs than heavier soils. The weight of the sowing unit is either not enough or already too heavy. The target is to ensure even depth control for precise seed placement in various soil conditions and working speeds by maintaining a constant contact force with a consistent weight on the gauge wheel. Sensor technology converts this information and a double-acting hydraulic cylinder in the parallelogram adjusts the oil pressure to guide the sowing row to an even depth. Each sowing unit is individually monitored and automatically regulated on the go. With the GEOFORCE system, all rows keep up the same sowing depth, also those running in more compacted areas like tractor tracks.

Benefits, Comfort and Savings

The Kverneland GEOFORCE reduces operator's workload, monitors and improves the quality of sowing. GEOFORCE ensures an even seed placement and plant development. This will decrease farm production costs and lead to a higher, better-quality yield.

Uniform germination and an even field emergence promote quick soil coverage by leaves, reducing weed pressure. Less chemicals or mechanical weeding passes are required. The risk of losses due to bird damage attracted by uncovered seeds or missing emergence due to too deep seed placement is minimised. Smaller seeds at shallow sowing depth, like rape, benefit from the ability to release the row, making it independent of row weight. With pressure generated precisely where needed on the row, optimal seed placement is ensured. Kverneland GEOFORCE reduces fuel consumption by minimising bulldozing effects and enables smooth operation at higher working speeds. Moreover, the maintenance cycles and lifetime of the coulters and wearing parts is extended due to the adapted pressure adjustment on the go.

Kverneland Sync for Optima F – The Implement Gateway

Always Connected – Easy and Direct

With Kverneland Sync, your Optima F precision drill is continuously connected to Kverneland’s online services. Designed for efficiency and ease, Kverneland Sync ensures seamless data transfer to IsoMatch FarmCentre and Kverneland ServiceCentre, optimizing your Optima F’s connectivity for better machine management.

Remote Service – Minimize Downtime

Kverneland Sync offers remote diagnostics, allowing technicians to quickly analyze and address electronic issues on your Optima F from a distance via the Kverneland ServiceCentre. This feature helps to minimize downtime in the event of a breakdown. See how it works: Always connected

Task Management – Enhance Reporting and Transparency

Kverneland Sync provides all relevant data in IsoMatch FarmCentre, our integrated farm management platform, enabling real-time tracking, performance measurement, and secure data storage. This is especially useful for machine cooperatives, streamlining logistics and invoicing. Additionally, Kverneland Sync enables geofencing to help protect your Optima F against theft, with an accumulator that allows you to locate your planter even when it’s not connected to a tractor.

Micro-drill for Optima HD-II and SX sowing units

The demand for microgranule applicators is increasing. Micro nutrients and also small amounts of insecticides or fungicides ensure the best start of the crop.

The electric driven micro-drills for the Optima HD-II and SX sowing units have been designed as backpack behind the sowing units and offer a hopper capacity of 17 liters.

They are electrically driven and ISOBUS controlled. The metering device consists of a wear-resistant plastic housing with exchangeable cell wheels made of stainless steel. This ensures the precise metering of the micro granules.

Operator’s safety

The engineers had focus on highest level of operator’s safety by offering easy and safe handling of the applicator. Therefore, the operator can exchange the cell wheels even when the hoppers are full of micro granule. There is no need to empty them first, reducing the operator’s risk of getting in direct contact with the granules.

A plus for the environment

The micro granules fall freely into the seed furrow without any air support, minimising the emission of dust. Therefore, the new micro-drill fully complies with the current guidelines for emission control of any granules applied.

Precision Farming

The comfortable, fully ISOBUS integrated control system allows the adaption to the stop and starting points of the seed row. This ensures precise shutting on and off at the end of the field and in tramlines (without overlaps or faults).

Precision Farming

Precision Farming

When deciding what equipment to purchase, it is not always easy to find the optimal solution in the broad market offering of today. Technology is developing fast and tractors and implements are more and more equipped with high tech electronics. We understand this complexity and are committed to provide you with easy farming solutions. Therefore these cost-efficient ISOBUS Universal Terminals, IsoMatch Tellus PRO and IsoMatch Tellus GO+ are made for easy machine control and efficient farming.

With its advanced hardware and software features, the IsoMatch Tellus PRO provides the optimal precision farming solution for an all-in-one control system inside your tractor cab.

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything a farmer needs to get the maximum out of his machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives the farmer the opportunity to view and control two machines and processes simultaneously.

Work easy. Be in control.

IsoMatch Tellus GO+ is especially developed for controlling the machine in a simple way. The farmer is in full control of the machine in exactly the way he wants. Easy set up the machine with the soft keys via the 7-inch touch screen. And, optimal control while driving, just use the hard keys and rotary switch. Controlling the implement has never been so easy.

This can be you your first step into Precision Farming

IsoMatch Tellus GO+ makes it easy to control any ISOBUS machine from your tractor cab. IsoMatch GEOCONTROL enables you to achieve higher yields, lower costs and do your work with less hassle. This licence key is divided in two parts, Section Control and Variable Rate Control, which are available from the IsoMatch Shop. Now you can buy the specific functionality that you need.

The IsoMatch Grip is an ISOBUS auxiliary device developed for great operator comfort and efficient machine control. Its ergonomic shape and the complete freedom of assigning and controlling a total of 44 implement functions from one device are unique in the market today. From your fingertips you have endless possibilities to operate all machine functions as desired. And assignments are saved per machine making it even more applicable to your needs.

With manual guidance you are perfectly on track.

The IsoMatch InLine is a light bar which allows easy manual guidance. It is the perfect assistant to get you as close as possible to your desired A-B line. Mounted in the line of sight, you can easily see the distance from the A-B line and to which direction you should steer for the ideal position. The display of the IsoMatch InLine also displays the status of the machine sections, which adds more comfort of use. The LEDs can be dimmed for night operation.

SMART

Distance to A-B line with LED indication and a numeric display

EFFICIENT

Manual guidance in combination with IsoMatch GEOCONTROL

EASY

Displays status of machine sections

The essential accessory for IsoMatch GEOCONTROL.

The IsoMatch Global 3 is the GPS antenna, with DGPS accuracy, in the IsoMatch product range. It enables satellite navigation for site-specific section control, variable rate application, manual guidance and field registration.

SMART

Allows manual guidance, automatic section control and variable rate in combination with IsoMatch GEOCONTROL

EFFICIENT

DGPS accuracy without additional subscription fees

EASY

Easy to fit with mounting brackets included

The IsoMatch Eye is the camera option in the IsoMatch product range.

IsoMatch Eye is a camera that has been developed for use with our sophisticated IsoMatch Tellus GO+ and IsoMatch Tellus PRO dual screen terminal. The IsoMatch Eye is switchable from rear view to standard view.

It gives you full control and overview of entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety e.g. when reversing the machine or manoeuvring around obstructions.

SMART

Changeable from rear view to standard view

EFFICIENT

Full control and overview of entire machine operation

EASY

Night vision by integrated LED’s

IsoMatch MultiEye is an accessory for connecting multiple cameras to the IsoMatch Universal Terminal.

With the IsoMatch MultiEye you can connect multiple cameras to the IsoMatch Tellus PRO or IsoMatch Tellus GO+ Terminal. You can easily switch between the cameras without the need for an additional screen in you tractor cabin. It gives you full control and overview of the entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety when reversing the machine or manoeuvring around obstructions.

SMART

You can connect up to four IsoMatch Eye cameras and easily switch between the cameras with the remote control box which is standard included.

EFFICIENT

Full control and overview of entire machine operation from every side you want.

EASY

Night vision by integrated LED’s which increases the safety when reversing the machine or manoeuvring around obstructions.

Made for smart, efficient and easy farming

IsoMatch GEOCONTROL is an advanced software application within the IsoMatch Tellus PRO and IsoMatch Tellus GO+ that helps you to control all ISOBUS compatible Kverneland Group machines such as sprayers, spreaders and seeders! Combined with a GPS receiver it fulfils the future needs in terms of easy, smart and efficient farming!

GEOSEED increases the yields of row crops and ensures maximum efficiency. Seeds are placed perfectly in line and in relation to each other.

GEOSEED is offered in two different levels:

GEOSEED Level 1 is the synchronization in the machines working width. This improves the distribution of seeds up to perfection in parallel or diamond pattern: Positive effects are the best use of nutrients, water and sun. Also the wind and water erosion is decreased.

GEOSEED Level 2 is the synchronization in the whole field. This is the necessary requirement for interrow cultivation, also across the seeding direction. GEOSEED is the only system in the world, that makes this mechanic weeds control possible!

Technical specifications

Technical specifications

Download brochure| Model | Optima F | |

|---|---|---|

| Frame type | parallel hydr. fold | |

| Working width (m) | 6.00 | |

| No. of SX sowing rows | 8 - 12 | |

| Row width SX row (cm) | 45-80 | |

| Transport width (m) | 3.00 | |

| e-drive II, ready for GEOSEED® | Standard | |

| Fan drive 1000rpm | Option | |

| Fan drive 800rpm | Standard | |

| Hydraulic fan drive | Option | |

| Linkage | CAT III N/CAT III | |

| Tyres 26x12.00STG | Standard | |

| Hydraulically operated track marker | Standard | |

| Hydraulically frame ballasting kit | Option | |

| No. of rows with front hopper f-drill / iXtra LiFe | 8 - 12 - 16 | |

| Micro granule applicator micro-drill | Option | |

| PUDAMA | Option | |

| GEOFORCE | Option |

Technical specifications

Technical specifications

Download brochureOptima F |

|

Frame |

Parallel hydraulic folding |

Working width / transport width (m) |

6.00 / 3.00 |

Type of sowing row |

HD-II, SX high speed sowing row |

Number of rows * |

8 - 16 |

Row distance (cm) * |

37.5 - 80 |

Seed hopper capacity (l) |

30 / 55 / 60 |

e-drive II / ready for GEOSEED® |

Standard |

f-drill |

Option |

iXtra LiFe |

Option |

micro-drill |

Option |

* Depending on type of row