We care with utmost precision and efficiency

We believe that with intelligent and efficient farming systems we contribute to sustainable agriculture, serving the world’s growing population.

High yields in row crops with reduced input and environmental impact

Farmers are currently faced with challenges which are not easy to reconcile at first glance.

On the one hand the costs for fertiliser have risen exponentially and resources are limited. Still, healthy plant growth is the basis for a successful yield and safe food production. At the same time, the protection of the environment has become a key topic of today’s agriculture.

Due to the risk of contaminated groundwater and local over-fertilisation with organic fertilisers, recent European regulations, rules and policies have defined new standards and reduced the kinds of components allowed.

Moreover, farmers are confronted with a decreasing acceptance for fertiliser and crop care products in society.

Fertilisation ensures the supply of nutrients to the crop, but over-fertilization often has undesirable effects on the environment and the ecosystem of the land.

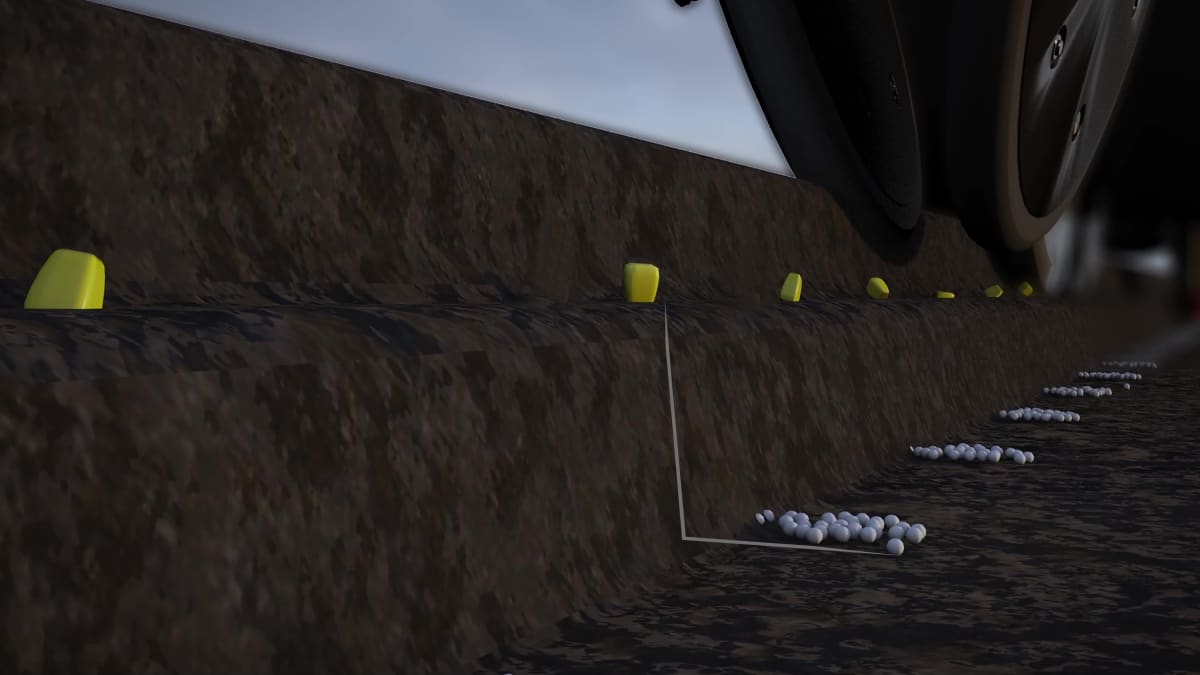

Conventional band application places a continuous band of fertiliser also between the plants, where the roots cannot reach it. This is the amount of fertiliser simply wasted and washed out.

With PUDAMA the amount and location of the fertiliser is precisely defined. The nutrients are only deposited where the roots of the grain can reach it and only as much as needed. Synchronised with the seed application at high speeds, a cloud of fertiliser is placed under each maize corn during maize seeding.

Every seed has an optimal fertiliser depot at its disposal which is completely absorbed by the plants. In this way, loss and leaching is avoided and the production of fertiliser raw materials can also be reduced.

In brief, PUDAMA is increasing the efficiency in the use of mineral starter fertiliser in maize – thus maintaining 100% yield whilst saving at least 25% starter fertiliser.

Conventional band application system

PUDAMA application system

A fertiliser depot is produced and deposited analogous to the driving speed and seed distance in the furrow. The fertiliser is placed by an air stream 5cm below and side wards to the seed.

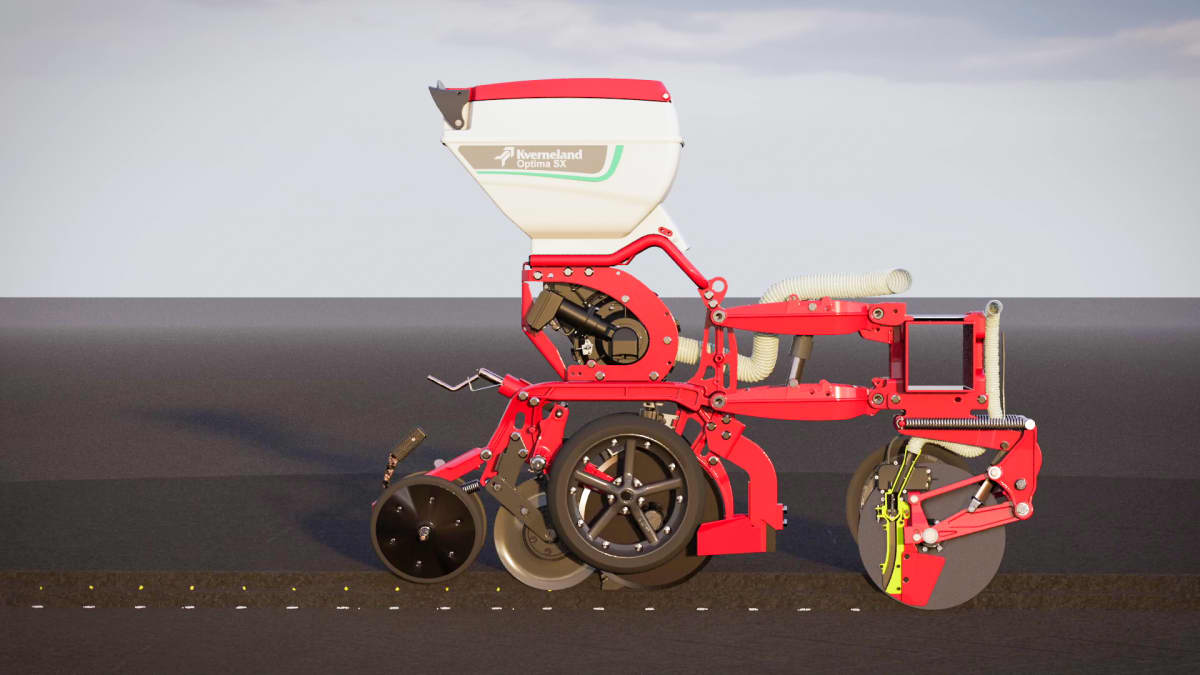

The PUDAMA system has been incorporated in the Optima TFprofi and Optima F with SX high speed rows.

The PUDAMA system ensures the reduction of at least 25% of starter fertiliser compared with the continuous application of fertiliser - whilst maintaining 100% yield.

With the PUDAMA technology on the two Kverneland models Optima TFprofi SX and Optima F SX, farmers can save a lot by reducing fertiliser, transport and work costs. For example, if a farmer with 300ha of maize uses 150kg/ha DAP 18-46 in the conventional way, he would save 37.5kg/ha of fertiliser with the PUDAMA system. This means a saving of 7,875€* for 300ha.

1. PUDAMA Application

2. Maize without Fertiliser Starter

3. Conventional Band Fertiliser

In Germany up to 81,000 tonnes of fertiliser could be saved annually in future with the PUDAMA system, which would mean that 16,200 tonnes less of pure nitrogen and phosphate would be used. This corresponds to a saving of 25 % of the starter fertiliser currently used annually at the same high yield level.

The PUDAMA system has been incorporated in two models of the Optima range: i.e. Optima TFprofi and Optima F with SX high speed row, offering reliability by high expertise in precision drills and proven machinery – proven by independent results from Universities.

After the studies of the PUDAMA system carried out in Germany with excellent test results, in 2023 Kverneland extended the scope of operation and initiated a PUDAMA campaign with field trials in six European countries at 30 different locations to show proof the practical relevance of the PUDAMA technology in farmers’ local conditions. Various institutes, universities, agronomists and farmers were involved to follow-up the trials in practice under different conditions.

The test fields were exposed to real-life risks: Thus, some trials failed due to birds picking up the seeds or lack of water in the summer in some eastern European countries where two trial locations had below 150 l/m2 water. However, the results of the remaining trials are convincing and confirmed the scientific results!

"PUDAMA - 100% yield whilst saving at least 25% starter fertiliser.”

PUDAMA, was developed by Kverneland Group Soest GmbH in recent years in cooperation with the TH Cologne, Institute for Construction and Agricultural Machinery Technology of Cologne.

For your reference, the results of these studies have been published here in English and German.

Dr. Max Bouten during the test

Listen in to the interview to hear more about the background, studies and further details of the PUDAMA project.

Participating in the interview are Dr. Max Bouten, Product Director for Smart Farming, Volker Schanzenbach, R & D Manager Kverneland Group Soest GmbH and Katrin Schrewe, Marketing Manager Kverneland Group Soest GmbH.