S series

Tillage | Power Harrow

Kverneland power harrows with strength and reliability – power harrows you can rely on!

The Kverneland S series is a heavy-duty power harrow for tractors up to 250hp.

The advantages of this Power Harrow

- Strong resistance to abrasion and torsion

- Thorough crumbling over entire working width

- Maximum versatility with all types of seed drills

- Reduced peak load and fuel consumption

- Wide choice of rear rollers

Description

The Kverneland S series is a heavy-duty power harrow for different operations and soil types. Robustly designed for use on tractors up to 250hp, with the Kverneland heavy-duty trough design and Quick-Fit tines the S series is the right solution for large farms and contractors.

The S series is equipped with Quick-Fit tines as standard. Active tines with more aggressive action are available for optimum performance in difficult soil conditions. The trough design provides a large clearance between the tine holders and the trough bottom. This allows large amounts of residue and stones to pass freely without blocking. Solo use or in combination with the heaviest Kverneland cultivator mounted seed drills are possible.

Optimal seedbed preparation with Kverneland power harrows

There are good reasons for seedbed preparation with Kverneland Power Harrows. Efficient seedbed preparation is needed for healthy plant growth as the basis for yield and profit, as well as for a safe food production. The need for more sustainable practices and the economic pressure have driven the development of next generation technologies. An optimal seedbed with a load-bearing seed horizon in which the seed can be placed at an absolutely even depth over the whole area of the field is the foundation for high field emergence and thus for high yields. It requires an unbroken connection between the seed horizon and the capillary water conducting lower layer to ensure germination in the absence of rainfall.

Additionally, rapid heating of the soil and adequate oxygen supply to the germination seeds as well as fine crumbled and uniform reconsolidated seedbed for an optimal seed coverage is important too.

What makes a perfect seedbed?

• Even distribution of plant residues (to ensure best light and nutrient supply of the crops).

• No deep tracks or compaction that restrict root growth

• Optimal depth without excessive tillage

• Fine crumb in sowing zone, coarse structure above at the surface for a weatherproof finish

• Good capillary connection to ensure moisture availability

Benefits of seeding combinations with Kverneland power harrows

Power harrows have long since become typical combination machines because they are almost independent of the soil conditions. On heavy soils, it achieves intensive crumbling. In light conditions, it can work more shallow and at lower rotor speed. The sets of tines rotate on vertical axles for totally horizontal tillage of the soil – no inversion of soil layers and no vertical compression leading to hardpan formation. Consequently, there is no better alternative for seedbed preparation. A power harrow together with a seed drill is finally an economic high performance combination. Seed bed preparation and seeding in one pass! All Kverneland power harrows models are exclusively designed to be combined with Kverneland seed drills either modular with front tank and coulterbar or with cultivator mounted seed drills.

Highlights

- Strong resistance to abrasion and torsion of the self-supporting trough

- Robust headstock

- Thorough crumbling over entire working width by four rotors (8 tines) per metre

- Max. versatility – easy and simple combination with all types of seed drills

- Reduced peak load and fuel consumption

- Wide choice of rear rollers

Features

Features

The S Series is equipped with Quick-Fit tines as standard. These are secured by a special pin and clip mounted in the tine holder. Tine replacement is, therefore, very easy without the need for tools. Downtime can be further minimized by an optional carbide layering of the tines. This will ensure a long liftime and minimum wearing even in tough and abrasive soils.

Depending on soil conditions, there is the choice of Standard, Active tines, carbide-layered and XHD carbide tines.

Active tines

The active tines ensure optimum penetration in hard or uncultivated soil. Their unique shape allows the tine to pull itself into the ground. This gives a constant working depth and also prevents the machine from lifting out of the ground in hard dry soil conditions. In addition, it creates additional re-compaction at the packer roller. The active tine lifts the material and pushes it in front of the power harrow. This gives an optimum levelling effect even in tractor tracks. In mulch conditions the active tines can work directly into stubble and hard soil. The special shape of the tines keeps residues on the surface and this gives a big advantage against erosion.

XHD tine

The XHD Carbide reinforced tines are protected against extremely abrasive soil conditions. These tines are designed to offer you longer lifetime, keeping costs and downtime to a minimum in environments where standard tines are wearing too fast.

Helical tine positioning

The tines are arranged in varying angle positions in order to prevent damage caused by stones and ensure even levelling. 4 rotors per meter and the helical tine positioning reduce the peak loads on the driveline which results in smoother running and less fuel consumption. All gears are hardened in the trough for a long lifetime.

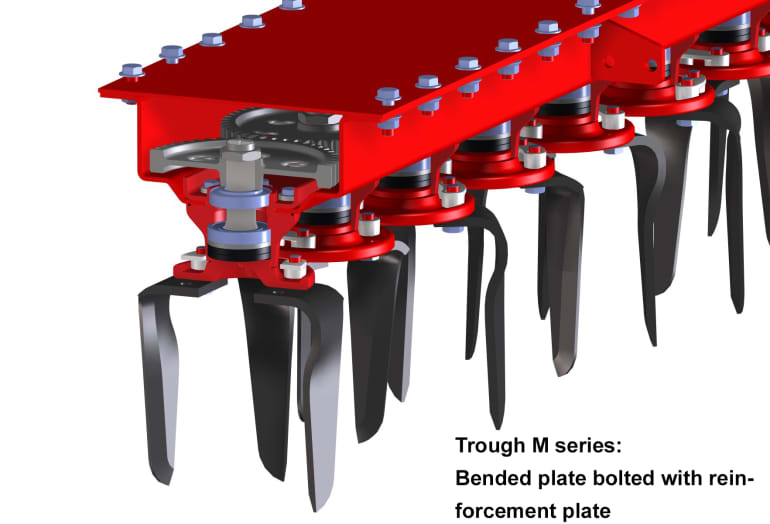

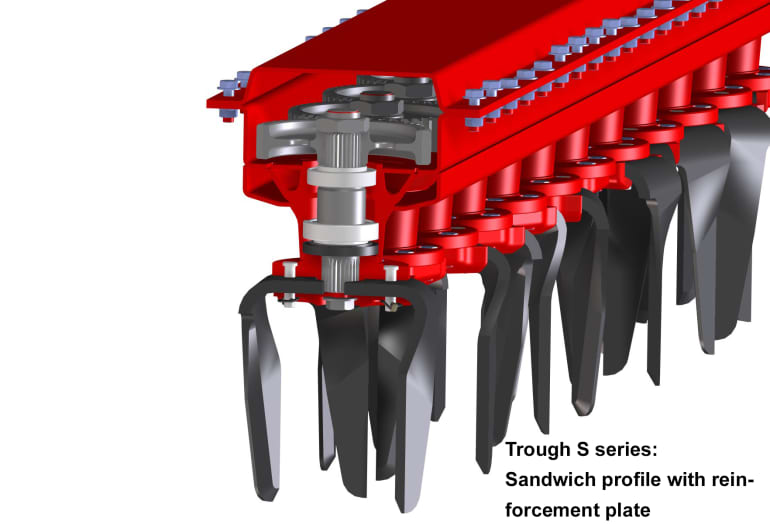

For optimum performance in difficult soil conditions, the robust and self-supporting trough design provides a large clearance between the tine holder and trough bottom. This allows large amounts of residues and stones to pass freely without blocking and provides excellent results in mulch conditions.

Model |

Trough dimension (mm) |

Gears |

Ø Shaft (mm) |

Bearings (mm) |

Bearing distance (mm) |

Rotor clearance (mm) |

M series |

140 x 400 |

tempered |

40 & 45 |

80 - 90 |

70 |

98.25 |

H series |

165 x 400 |

tempered & hardened |

45 & 50 |

90 - 100 |

84.5 |

90.5 |

S series |

200 x 400 |

hardened |

55 & 60 |

110 - 120 |

110.5 |

100 |

Re-consolidation for a stable soil structure

Rollers ensure re-compaction of the soil as final step of the optimum seedbed preparation. By reducing soil porosity and limiting evaporation, all plants will have the same access to nutrients, moisture and light. This will give the crop a good start for a perfect growth and high yields.

The right rollers for all types of soil and conditions:

Actipack ø560mm – 205 kg/m

- For medium to heavy soils, also in wet, stony and sticky conditions due to the independent skids and knives

- The cutting discs break the larger clods whilst the adjustable knives cut the remaining clods resulting in optimal clod breakdown and fine seedbed preparation

Cracker Packer ø550mm – 200kg/m

- For medium to heavy soils

- Real stripe-wise reconsolidation (12.5cm) in front of seed coulters – only 50% of the soil surface is rolled

- Good absorption of water

- Sufficient soil left loose for covering of seeds

- Good crumbling effect especially on heavy soils

- Smooth rings and passive-angled knives – no blocking when used in mulch conditions

Actiline Roller ø550mm – 185 kg/m

- For light to medium and heavy soils

- Trapezoidal roller with relatively narrow crest width of 40mm

- Stripe-wise consolidation and V shape furrow in front of the CX-II seed coulter bar

- Supporting water holding capacity and oxygen exchange

- Good carrying capacity with full self-cleaning effect

- Crests support the constant drive of the roller and avoid slip in light or tough and wet conditions

- Two different ring distances of 12.5cm and 15cm

- Carbide-coated scrapers on request

Tooth Packer roller ø575mm – 160kg/m

- Medium to heavy soils

- Good carrying capacity

- Good self-cleaning effect

- Central adjustable scraper bar with independently adjustable scrapers

- Carbide coated scrapers on request

- Most versatile roller – especially as part of heavy power harrow/seed drill combination

Cage roller ø550mm – 90kg/m

- Light to medium soil and dry working conditions e.g. seed bed preparation for potato planting

- 10 bars for a good loading capacity and option in wet conditions

Flexibility is key!

The coulterbar can be easily coupled and uncoupled with a coupling hook similar to the front loader coupling. Track markers are attached to the power harrow. Therefore, the power harrow is ready for solo operation within short time. The coulterbar is attached with the Euro-Connection directly to the roller frame and can quickly and easily be hitched thanks to the readily accessible hydraulic and electronic interface.

The e-drill is exclusively designed to be combined with Kverneland power harrows.

Technical specifications

Technical specifications

Download brochure| Model | S series | S series | S series | S series | |

|---|---|---|---|---|---|

| Maschine type | rigid | rigid | rigid | rigid | |

| Working width (m) | 3.0 | 3.5 | 4.0 | 4.5 | |

| Transport width (m) | 3.0 | 3.5 | 4.0 | 4.5 | |

| Trough dimension (mm) | 200 x 400 | 200 x 400 | 200 x 400 | 200 x 400 | |

| PTO input speed (rpm) | 1,000 | 1,000 | 1,000 | 1,000 | |

| Overload protection on PTO shaft (Nm) | 2,500 | 2,500 | 2,500 | 2,500 | |

| Number of rotors | 12 | 14 | 16 | 18 | |

| Standard rotor speed 1000rpm (rpm) | 298 | 298 | 298 | 298 | |

| Optional rotor speed 1000rpm (rpm) | 365 and 435 | 365 and 435 | 365 and 435 | 365 and 435 | |

| Tapered bearing distance (mm) | 110.5 | 110.5 | 110.5 | 110.5 | |

| Rotor clearance (mm) | 100 | 100 | 100 | 100 | |

| Number of tines | 24 | 28 | 32 | 36 | |

| Tine dimension (mm) | 18 x 330 | 18 x 330 | 18 x 330 | 18 x 330 | |

| Quick-Fit tines | Standard | Standard | Standard | Standard | |

| Active tines | Option | Option | Option | Option | |

| 3-point Linkage: Top | CAT II/CAT III | CAT II/CAT III | CAT II/CAT III | CAT II/CAT III | |

| 3-point Linkage: Low | CAT II/CAT III N/CAT III | CAT II/CAT III N/CAT III | CAT II/CAT III N/CAT III | CAT II/CAT III N/CAT III | |

| Depth adjustment | manual | manual | manual | manual | |

| Rear levelling bar | Option | Option | Option | Option | |

| Track eradicator | Option | Option | Option | Option | |

| Roller offering | Cage roller (ø 550mm), Tooth Packer roller (ø 575mm), Actiline roller (ø 550mm), Actipack roller (ø 560mm) | Cage roller (ø 550mm), Tooth Packer roller (ø 575mm), Actiline roller (ø 550mm), Actipack roller (ø 560mm) | Cage roller (ø 550mm), Tooth Packer roller (ø 575mm), Actiline roller (ø 550mm), Actipack roller (ø 560mm) | Cage roller (ø 550mm), Tooth Packer roller (ø 575mm), Actiline roller (ø 550mm), Actipack roller (ø 560mm) | |

| Ready to carry or integrate seeding eq. | Option | Option | Option | Option | |

| Lighting set | Option | Option | Option | Option | |

| Total weight (kg)* | 1,900 | 2,080 | 2,290 | 2,560 | |

| Minimum power requirement (kW/HP) | 74/100 | 74/100 | 74/100 | 74/100 | |

| Maximum power requirement (kW/HP) | 184/250 | 184/250 | 184/250 | 184/250 |

* Approx. weight with levelling bar, tooth packer roller ⌀ 575mm and PTO shaft approx.

Technical specifications

Technical specifications

Download brochureModel |

Working width (m) |

No. of rotors/tines |

Weight with packer roller (kg) |

Min./max. HP |

S series |

3.0 |

12/24 |

1,670 |

100/250 |

S series |

3.5 |

14/28 |

1,950 |

100/250 |

S series |

4.0 |

16/32 |

2,225 |

100/250 |

S series |

4.5 |

18/36 |

2,510 |

100/250 |

* Approx. weight with levelling bar, tooth packer roller ⌀ 575mm and PTO shaft approx.