Kverneland Enduro / Enduro Pro

Tillage | Stubble cultivator

Stubble cultivation: incorporation, levelling and consolidation one pass

With the Enduro or Enduro Pro, Kverneland provides a cultivator which is the right choice for all conditions and for a wide range of applications. The stubble cultivation, especially within a minimum tillage cultivation program, conserves soil structure and moisture and limits erosion. It is an operation which requires great consideration.

The advantages of this Stubble cultivator

- Full cutting system (FCS)

- Perfect mixing and levelling

- Low pulling force required

- Wide range of rollers

- Reduced maintenance & stone protection

Description

The Kverneland Enduro and Enduro Pro cultivators deliver high performance in all soil conditions, offering versatility and efficiency for modern farming. Their 3-row tine layout ensures excellent mixing and residue handling, even in heavy conditions.

The Enduro Pro enhances user comfort with hydraulic on-the-go depth adjustment via a double parallelogram roller linkage, saving time and boosting productivity. The standard Enduro offers reliable performance with simple hydraulic adjustment via spacers.

Optimized tine spacing (275–285mm) ensures smooth soil flow and intensive cultivation. The Enduro Pro works up to 35cm deep; the Enduro up to 30cm.

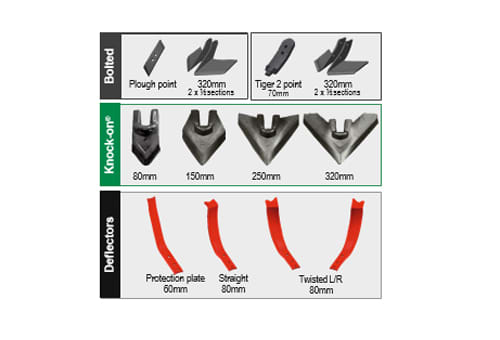

Both models support Triflex 700 and Share Bolt Tines which can be equipped with a wide range of shares to adapt to varying working depths and tasks. Seven share designs are available with the Knock-on® system, offering the fastest and easiest way to change parts on a cultivator - ideal for quick adaptation between jobs or replacing worn components.

The importance of stubble cultivation

Stubble cultivation is a key practice in conservation tillage and sustainable soil management, supporting soil structure, conserving moisture, and reducing erosion. These are critical factors for successful crop establishment in reduced and minimum-tillage farming systems.

Breaking the green bridge for disease and pest control

When crop rotation is limited or repeated, managing the green bridge is essential to maintain soil health and prevent the carryover of soil-borne diseases, volunteer weeds, and pest habitats like slugs. Strategic shallow cultivation after harvest disrupts these threats while reducing dependence on herbicides.

Encouraging volunteer germination & accelerating straw breakdown

An initial shallow stubble pass encourages volunteer crop germination, suppresses weed seed banks, and minimizes evaporation. A deeper second cultivation supports straw residue breakdown, aiding nutrient cycling and reducing disease pressure linked to crop residues.

Improving soil structure and enhancing pest management

Early post-harvest cultivation not only stabilizes soil structure, but also improves pest control by incorporating residues and consolidating the surface. This limits the movement of slugs, mice, and other pests while creating a more uniform seedbed for the next crop.

Features

Features

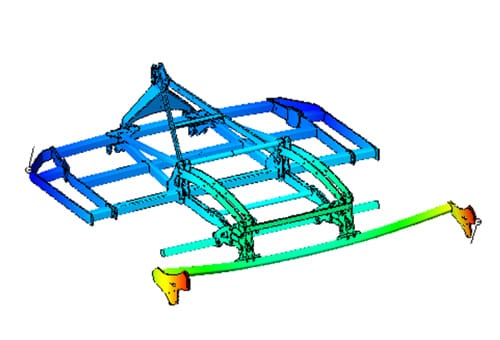

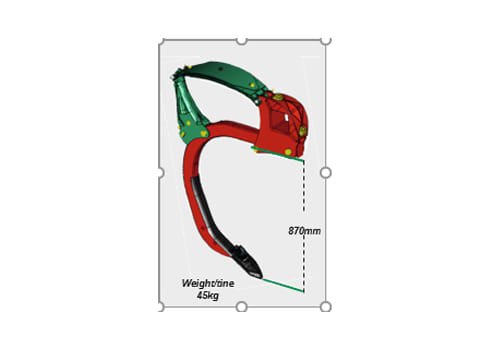

The frame is a result of a long study made by FEM (Finite Element Method) calculation to optimise the steel over the working width and proposing a strong structure suitable for tractors up to 350hp.

The complete Enduro/Enduro Pro range has been designed to be combined with the heaviest rollers in the range. All the most aggressive scenarios (deep working when turning, headland turns, transport tests, ...) have been considered to make the different frames as strong as possible and thus guaranteeing the proven Kverneland quality.

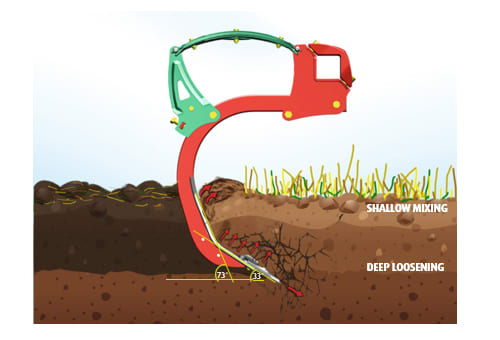

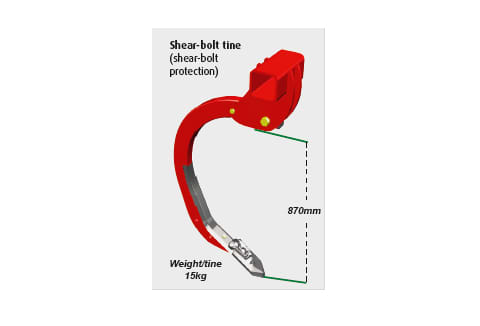

For stony conditions and high Penetration - Triflex 700 & Shear-bolt Tines

The auto-reset Triflex tine uses the well-known Kverneland leaf spring system to ensure a high point pressure of 700kg and a smooth release curve in case the tine hits an obstacle. A shear-bolt protection tine is also available. Both hollow, specially heat-treated tines are of a narrow design with two working zones which reduce the pulling forces whilst ensuring a perfect penetration even in heavily compacted soil. It is the perfect choice for deep loosening and working on heavier soil types strewn with stones.

The Triflex 700 and shear-bolt tines can be equipped with different shares to adapt to varying working depths and tasks. Seven options of share design are available with the Knock-on® system. This is the easiest way of changing parts on a cultivator, necessary when adjusting the machine for the next job or when changing wearing parts.

- 700 kg release force and 27 cm release height

- Proven overload protection

- Intensive mixing and crumbling

- Constant cutting depth

- Deep and shallow – full share range

- Knock-on® system for fast share exchange

- Carbide equipment

Leaving an even surface

In order to create an even surface for a fine seedbed, Kverneland offers various options of levelling tools for the Enduro and Enduro Pro models. The levelling equipment is directly linked to the roller. If the working depth changes via the roller, the levelling equipment will stay at the same optimal levelling position thanks to the parallelogram on the Enduro Pro model.

Levelling tines are a very easy and economic way to handle normal straw conditions on light to medium soil types. When it comes to heavy amounts of residues and in soil conditions with clay or loam, the levelling discs are more suitable.

Both versions are overload protected by a spring or an elastic rubber buffer and mounted via a parallelogram (on Enduro Pro) to avoid damages in stony or other difficult conditions. Individual springs ensure the individual release of tines or discs and keep levelling quality even in stony conditions. The working angle of the levelling tines or discs can be adjusted in order to increase or decrease the aggressive position. The centralized levelling adjustment of the complete levelling device is easily done via adjusting handles.

To respect the transport width on the mounted versions with 3.00m and 3.50m working width, the outer tines or discs can be hydraulically or mechanically folded in.

A rear triple finger harrow (Enduro Pro) provides levelling and controls weed development by pulling the weeds out of the ground so that the roots dry out in the sun. This is particularly interesting with rhizome and other weeds that could start growing again if they are pressed by a packer immediately after cultivation. Gauge wheels control the working depth of the machine. The triple finger harrow can be adjusted by the setting angle and the hydraulic pressure via the parallelogram according to conditions.

User comfort is key - easy adjustment

Kverneland always focuses on safe operation and user comfort. With all the adjustments being done without the need for tools, a lot of precious time is saved!

Adjusting the Enduro and Enduro Pro is easily done. When setting the working depth of the tines, the parallelogram design allows the correct depth of the levelling discs to be maintained without adjustment in most conditions.

In addition, there is hardly any maintenance to be done apart from changing wearing parts.

The Enduro can simply be connected/disconnected from the tractor due to the easy hitch linkage. And this is even more comfortable with the hydraulic depth adjustment.

The roller on a cultivator is an elementary tool with different tasks:

- Consolidation of the soil structure for a weatherproof finish

- Cutting and breakdown of large fissures during the wetting and drying process

- Finalising the levelling and helping retain valuable moisture

- Supporting the depth control

The choice of the right roller depends on the soil type, soil condition, crop rotation and lifting capacity of the tractor.

Actipack ø560mm - 205 kg/m

- The Actipack roller displays its superb working qualities especially on medium to heavy soils and also in wet, stony and sticky conditions thanks to the independent skids and knives.

- The cutting discs break the larger clods whilst the adjustable knives cut the remaining clods resulting in optimal clod breakdown and fine seedbed preparation.

Actiring ø540mm - 160 kg/m

- The Actiring roller is a lighter variant of the Actipack, using the same frame structure and knife system.

- The discs have been replaced by a “V” profile ring, this is saving 60kg/m, which is of critical importance for reducing lifting requirements for mounted equipment.

- Actiring is not recommended in stony conditions

Actiflex ø580mm - 160 kg/m

- The Actiflex roller has been made to create an intensive mixing with all types of conditions, even stony ones.

- The rings are made with spring steel to have a high resistance against stress at high speed.

- Actiflex rings are separated by skids to prevent any accumulation inside the roller.

- This roller is the ideal tool to create a nice seedbed and enhance the weeds regrowth after harvesting

Actipress Twin ø560mm - 220kg/m (not on folding models)

- U-profile for high carrying /rolling capacity on light soils

- Clod breaking also in heavy conditions

- Possibility to make different soil profiles by locking the rocking (even or corrogated)

- Self-cleaning effect thanks to the twin u-ring concept

- High stability thanks to the oscillating frame

- High and homogenous consolidation

- Can also work in stony conditions

- Weight/m when full of soil : 250 kg/m

Actipress Single ø560mm - 150kg/m

- Single rotor with U-profile for high carrying /rolling capacity on light soils

- Also for stony conditions due to wide pitch

- 3 models available for a more uniform or rough surface:

with blades/with carbide blades / without blades - More compact design and reduced weight especially suitable for three-point mounted implements.

- Clod breaking also in heavy conditions

- Weight/m when full of soil : 188 kg/m

Cage roller ø550mm - 90 kg/m

- 10 bars for a good loading capacity and operation in wet conditions

- Effective crumbling action

Double cage roller ø400mm (tube/flat) - 160 kg/m

- Good crumbling and levelling effect

- Precise depth control

- High carrying capacity

A rear triple finger harrow (Enduro Pro and Turbo) provides levelling and controls weed development by pulling the weeds out of the ground so that the roots dry out in the sun.

This is particularly interesting with rhizome and other weeds that could start growing again if they are pressed by a packer immediately after cultivation. Gauge wheels control the working depth of the machine.

The triple finger harrow can be adjusted by the setting angle and the hydraulic pressure via the parallelogram according to conditions.

For the efficient establishment of cover crops in one pass with stubbling, Kverneland offers two options:

- The rigid and trailed models of the Enduro and Enduro Pro can be equipped with the Kverneland integrated seed drill, a-drill. The a-drill is prepared for the establishments of fine rape seed or mixtures of different diameters seeds (leguminous plant, cruciferous, etc.) Different metering rotors and two types of fans are available.

- Alternatively, the rigid and trailed models of the Enduro and Enduro Pro can be combined with a front hopper f-drill and one or two distribution head systems above the rear roller. In combination with the f-drill with ELDOS metering device, the seeds are metered, conveyed and distributed into the soil flow via a baffle plate, either before or behind the rear roller. Placing the seed before the rear roller of finger-following harrow ensures optimal seed-to-soil contact.

Technical specifications

Technical specifications

Download brochure| Model | Enduro 3000 | Enduro Pro 3000 | Enduro 3500 | Enduro Pro 3500 | Enduro 4000 | Enduro Pro 4000 | |

|---|---|---|---|---|---|---|---|

| Frame | mounted rigid | mounted rigid | mounted rigid | mounted rigid | mounted rigid | mounted rigid | |

| Roller width (m) | 3.00 | 3.00 | 3.50 | 3.50 | 4.00 | 4.00 | |

| Working width (m) | 2.85 | 2.85 | 3.42 | 3.42 | 3.85 | 3.85 | |

| Transport width (m) | 3.00 | 3.00 | 3.50 | 3.50 | 4.00 | 4.00 | |

| Type of tine | Triflex 700 tine with auto-reset leaf spring or tine with shear-bolt protection | Triflex 700 tine with auto-reset leaf spring or tine with shear-bolt protection | Triflex 700 tine with auto-reset leaf spring or tine with shear-bolt protection | Triflex 700 tine with auto-reset leaf spring or tine with shear-bolt protection | Triflex 700 tine with auto-reset leaf spring or tine with shear-bolt protection | Triflex 700 tine with auto-reset leaf spring or tine with shear-bolt protection | |

| Working depth (cm) | 5 - 30 | 5 - 35 | 5 - 30 | 5 - 35 | 5 - 30 | 5 - 35 | |

| No. of tine rows | 3 | 3 | 3 | 3 | 3 | 3 | |

| No. of tines | 10 | 10 | 12 | 12 | 14 | 14 | |

| Tine spacing (mm) | 285 | 285 | 285 | 285 | 275 | 275 | |

| Row spacing (mm) | 750 | 750 | 750 | 750 | 750 | 750 | |

| Linkage | CAT. II & CAT. III | CAT. II & CAT. III | CAT. II & CAT. III | CAT. II & CAT. III | CAT. II & CAT. III | CAT. II & CAT. III | |

| Underbeam clearance (mm) | 870 | 870 | 870 | 870 | 870 | 870 | |

| Levelling device | Levelling tines or Levelling discs | Levelling tines or Levelling discs | Levelling tines or Levelling discs | Levelling tines or Levelling discs | Levelling tines or Levelling discs | Levelling tines or Levelling discs | |

| Triple finger harrow | - | Option | - | Option | - | - | |

| Finger harrow (450x12mm) | Option | Option | Option | Option | Option | Option | |

| Roller offering | Cage roller (ø 550mm), Double Cage roller (ø 400mm), Actiring (ø 540mm), Actiflex (ø 580mm), Actipack (ø 560mm), Actipress Single (ø 560mm), Actipress Twin (ø 560mm) | Cage roller (ø 550mm), Double Cage roller (ø 400mm),Actiring (ø 540mm), Actiflex (ø 580mm), Actipack (ø 560mm), Actipress Single (ø 560mm), Actipress Twin (ø 560mm) | Cage roller (ø 550mm), Double Cage roller (ø 400mm),Actiring (ø 540mm), Actiflex (ø 580mm), Actipack (ø 560mm), Actipress Single (ø 560mm), Actipress Twin (ø 560mm) | Cage roller (ø 550mm), Double Cage roller (ø 400mm),Actiring (ø 540mm), Actiflex (ø 580mm), Actipack (ø 560mm), Actipress Single (ø 560mm), Actipress Twin (ø 560mm) | Cage roller (ø 550mm), Double Cage roller (ø 400mm), Actiring (ø 540mm), Actiflex (ø 580mm), Actipack (ø 560mm), Actipress Single (ø 560mm), Actipress Twin (ø 560mm) | Cage roller (ø 550mm), Double Cage roller (ø 400mm), Actiring (ø 540mm), Actiflex (ø 580mm), Actipack (ø 560mm), Actipress Single (ø 560mm), Actipress Twin (ø 560mm) | |

| Gauge wheel | 2 x 6.00x9 (mechanical) | 2 x 6.00x9 (mechanical) | 2 x 6.00x9 (mechanical) | 2 x 6.00x9 (mechanical) | 2 x 6.00x9 (mechanical) | 2 x 6.00x9 (mechanical) | |

| Depth adjustment (Roller) | hydraulic by spacers | hydraulic On-GO | hydraulic by spacers | hydraulic On-GO | hydraulic by spacers | hydraulic On-GO | |

| Min HP | 90 | 90 | 110 | 110 | 120 | 120 | |

| Max HP | 240 | 240 | 270 | 270 | 320 | 320 | |

| Total weight with Triflex 700 & Cage roller (kg)1) | 1750 | 1810 | 2100 | 2170 | 2200 | 2290 | |

| Total weight with Triflex 700 & levelling disc & Actiflex roller (kg)1) | 1870 | 1930 | 2260 | 2330 | 2550 | 2640 | |

| Total weight with levelling disc & Actipack roller (kg)1) | 2020 | 2080 | 2430 | 2500 | 2700 | 2790 |

1) Weights are given as an indication

2) Triple finger harrow (Ø 16mm; Length 750mm) with mechanical depth control wheels 2 x 6.00x9 on rigid models and 2 x 10.0/80-12 on fold models - no rear roller possible