Kverneland CTC

Tillage | Stubble cultivator

CTC – Cultivation from deep to shallow

Stubble cultivation, especially within a no-tillage or minimum tillage cultivation program, conserves soil structure and moisture and limits erosion. It is an operation which requires great consideration.

The advantages of this Stubble cultivator

- Complete cutting, perfect mixing & levelling

- Low pulling force needed

- Reduced maintenance

- Versatile from shallow to medium

- Large performance by high speed

Description

Kverneland CTC is available in different configurations depending on the conditions of use, but also on the power ability:

The CTC has a well-organised tine arrangement over 3 tine rows with 270mm tine spacing or 4 tine rows with 200mm tine spacing. The capacity with long residues has been a focus during the design process ensuring optimum mixing and intensive cultivation.

The tine position has been optimised to ensure a smooth soil flow across the entire working width but also around the transport wheels. A maximum working depth of 30cm is possible. The high inter-row clearance up to a maximum of 150cm and the underbeam clearance of 870mm ensure blockage-free operation.

The following share equipment belongs to Triflex 700 and Share Bolt Tines:

- Reversible point 65

- Knock-On 80

- Knock-On 150

- Knock-On 250

- Knock-On 320

- Wings share 320

- Tiger 3 (70 carbide point)

- Carbide wings share 320

The importance of stubble cultivation

Stubble cultivation is a key practice in conservation tillage and sustainable soil management, supporting soil structure, conserving moisture, and reducing erosion. These are critical factors for successful crop establishment in reduced and minimum-tillage farming systems.

Breaking the green bridge for disease and pest control

When crop rotation is limited or repeated, managing the green bridge is essential to maintain soil health and prevent the carryover of soil-borne diseases, volunteer weeds, and pest habitats like slugs. Strategic shallow cultivation after harvest disrupts these threats while reducing dependence on herbicides.

Encouraging volunteer germination & accelerating straw breakdown

An initial shallow stubble pass encourages volunteer crop germination, suppresses weed seed banks, and minimizes evaporation. A deeper second cultivation supports straw residue breakdown, aiding nutrient cycling and reducing disease pressure linked to crop residues.

Improving soil structure and enhancing pest management

Early post-harvest cultivation not only stabilizes soil structure, but also improves pest control by incorporating residues and consolidating the surface. This limits the movement of slugs, mice, and other pests while creating a more uniform seedbed for the next crop.

Features

Features

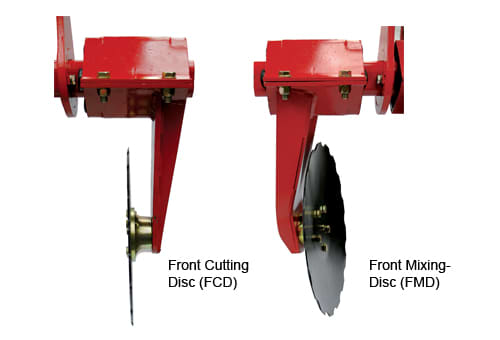

For the CTC 3 rows, Kverneland has developed a front disc system to cut or incorporate crop residues in front of the cultivator tines.

The disc system has a centralized hydraulic depth adjustment with master slave cylinder system and individual rubber disc protection. This overload system allows the disc to follow the ground contour very well.

As the working depth of the disc section is limited to 5cm, the required pulling force is insignificantly low.

Front Mixing Disc (FMD)

The front mixing disc (FMD) option is the ideal equipment that avoid any boiling effect in front of the tines especially with short wheat straw. The FMD system has notched hollow discs which are ideal when working in high amounts of crop residues. The FMD system pre-mixes any straw standing on the top of the stubble to ensure thorough mixing by the stubbling tines for improved incorporation. The adjustment of the pressure can be done on the move from the cab hydraulically.

Front Cutting Disc (FCD)

The FCD system has notched straight discs which are mounted in front of the first row of tines. The FCD system is ideal when working in maize straw for example, where the disc is cutting the straw directly in front of the tines. The straw is cut to improve the flow of material and prevent the machine from blocking.

- The CTC can be equipped with 3 rows of tines (spacing 270mm) and front working discs or with 4 rows of tines (spacing 200mm) ensuring optimum mixing and intensive cultivation.

- A maximum working depth of 30cm is possible

- The wing shares, when fitted, ensure that the entire working width of the machine is cultivated even when the machine is adjusted for shallow work.

- The high inter-row clearance up to a maximum of 150cm and the underbeam clearance of 87cm ensure blockage-free operation under any conditions.

- The outer wings are pre-loaded by hydraulic accumulators and can be adjusted to suit the various field conditions

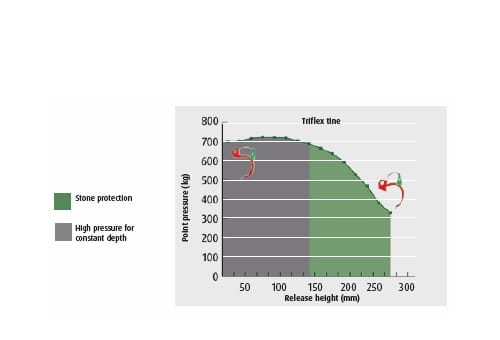

Triflex 700: High stability at deep operations

The auto-reset Triflex tine uses the well-known Kverneland leaf spring system to ensure a high point pressure of 700kg in work and a smooth release curve when the tine hits an obstacle. The Triflex tine with narrow design and special shape reduces the pulling forces while ensuring a perfect penetration in most compacted soil. It is the perfect choice for deep loosening and working on heavier soil types strewn with stones.

The Triflex 700 tine can be equipped with different shares to adapt to different working depths and tasks. 7 types of share equipments are available with the patented Knock-on® system. It is the easiest way of changing parts on a cultivator, either to adapt the machine to the job to be done or to change wearing parts.

The new 70mm Tiger 2 is available on CTC. The special design ensures progressive and high penetration and requires low pulling force. The special shape of the carbide plate resist against aggressive stony conditions. All points are also available with Knock-on® deflectors.

Click here for further details on the Knock-on® system.

There is a full range of levelling equipment and rear rollers available for CTC

Levelling discs:

- Rubber spring loaded, to follow the ground and protect against stones

- Border discs as standard

Levelling tines

- Good levelling capacity and good following of the ground contour

Combi disc harrow:

- Combination of a single disc gang with all roller type

- Hydraulic depth adjustment by spacers

- Adjustable angle depending of the mixing intensity required

Cage roller Ø 550mm - 90kg/m

- 10 bars for a good loading capacity and operation in wet conditions

- Effective crumbling action

Double cage roller Ø 400mm (tube/flat) - 160 kg/m

- Good crumbling

- Precise depth control

Actipack Ø 560mm - 205kg/m

- The Kverneland Actipack roller displays its superb working qualities especially on medium to heavy soils and also in wet, stony and sticky conditions thanks to the independent skids and knives.

- The cutting discs break the larger clods whilst the adjustable knives cut the remaining clods resulting in optimal clod breakdown and fine seedbed preparation

Actiring Ø 540mm - 160kg/m

- The Actiring roller is a lighter variant of the Actipack, using the same frame structure and knife system.

- The discs have been replaced by a “V” profile ring, this is saving 60kg/m, which is of critical importance for reducing lifting requirements for mounted equipment.

- Actiring is not recommended in stony conditions

Actipress Twin Ø 565mm - 220kg/m without soil

- U-profile for high carrying /rolling capacity in light soils

- Clod breaking also in heavy conditions

- High and homogenous consolidation

- Weight when full of soil: 250kg/m

Technical specifications

Technical specifications

Download brochure| Model | CTC 427 | CTC 527 | CTC 627 | CTC 420 | CTC 520 | CTC 620 | |

|---|---|---|---|---|---|---|---|

| Frame | trailed | trailed | trailed | trailed | trailed | trailed | |

| Working width (m) | 4.00 | 5.00 | 6.00 | 4.00 | 5.00 | 6.00 | |

| Transport width (m) | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | 3.00 | |

| Type of tine | Triflex 700 tine with leaf spring or shearbolt protection | Triflex 700 tine with leaf spring or shearbolt protection | Triflex 700 tine with leaf spring or shearbolt protection | Triflex 700 tine with leaf spring or shearbolt protection | Triflex 700 tine with leaf spring or shearbolt protection | Triflex 700 tine with leaf spring or shearbolt protection | |

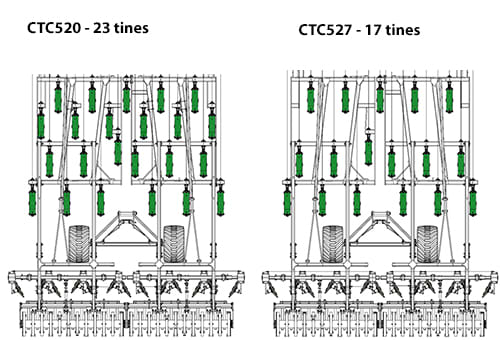

| No. of tine rows / tine spacing (mm) | 3 rows with 270mm | 3 rows with 270mm | 3 rows with 270mm | 4 rows with 200mm | 4 rows with 200mm | 4 rows with 200mm | |

| No. of tines / working width | 15 / 4.00 m | 17 / 4.60 m | 21 / 5.70 m | 19 / 3.80 m | 23 / 4.60 m | 29 / 5.80 m | |

| Mainframe (mm) | Square frame 200 × 200mm / Wing sections 100 × 100 mm | Square frame 200 × 200mm / Wing sections 100 × 100 mm | Square frame 200 × 200mm / Wing sections 100 × 100 mm | Square frame 200 × 200mm / Wing sections 100 × 100 mm | Square frame 200 × 200mm / Wing sections 100 × 100 mm | Square frame 200 × 200mm / Wing sections 100 × 100 mm | |

| Linkage | CAT. III or CAT. IV cross shaft or pulling eyes | CAT. III or CAT. IV cross shaft or pulling eyes | CAT. III or CAT. IV cross shaft or pulling eyes | CAT. III or CAT. IV cross shaft or pulling eyes | CAT. III or CAT. IV cross shaft or pulling eyes | CAT. III or CAT. IV cross shaft or pulling eyes | |

| Underbeam clearance (mm) | 870 | 870 | 870 | 870 | 870 | 870 | |

| Front equipment | FMD or FCD front disc section (only with 3 row version) | FMD or FCD front disc section (only with 3 row version) | FMD or FCD front disc section (only with 3 row version) | Levelling tines or levellings discs | Levelling tines or levellings discs | Levelling tines or levellings discs | |

| Levelling device | Levelling tines or levellings discs | Levelling tines or levellings discs | Levelling tines or levellings discs | Cage roller (ø 550mm), Double Cage roller (ø 400mm), Actiring (ø 540mm), Actipack (ø 560mm), Actipress Single (ø 560mm), Actipress Twin (ø 560mm) | Cage roller (ø 550mm), Double Cage roller (ø 400mm), Actiring (ø 540mm), Actipack (ø 560mm), Actipress Single (ø 560mm), Actipress Twin (ø 560mm) | Cage roller (ø 550mm), Double Cage roller (ø 400mm), Actiring (ø 540mm), Actipack (ø 560mm), Actipress Single (ø 560mm), Actipress Twin (ø 560mm) | |

| Roller offering | Cage roller (ø 550mm), Double Cage roller (ø 400mm), Actiring (ø 540mm), Actipack (ø 560mm), Actipress Single (ø 560mm), Actipress Twin (ø 560mm) | Cage roller (ø 550mm), Double Cage roller (ø 400mm), Actiring (ø 540mm), Actipack (ø 560mm), Actipress Twin (ø 560mm), Actipress Single (ø 560mm) | Cage roller (ø 550mm), Double Cage roller (ø 400mm), Actiring (ø 540mm), Actipack (ø 560mm), Actipress Twin (ø 560mm), Actipress Single (ø 560mm) | 200 or 500 l | 200 or 500 l | 200 or 500 l | |

| a-drill | 200 or 500 l | 200 or 500 l | 200 or 500 l | 400/60 x 15.5 or 480/45 x 17 | 400/60 x 15.5 or 480/45 x 17 | 400/60 x 15.5 or 480/45 x 17 | |

| Transport wheels | 400/60 x 15.5 or 480/45 x 17 | 400/60 x 15.5 or 480/45 x 17 | 400/60 x 15.5 or 480/45 x 17 | 340/55×16 | 340/55×16 | 340/55×16 | |

| Gauge wheels | 340/55×16 | 340/55×16 | 340/55×16 | Hydraulic or pneumatic | Hydraulic or pneumatic | Hydraulic or pneumatic | |

| Brake * | Hydraulic or pneumatic | Hydraulic or pneumatic | Hydraulic or pneumatic | 145/300 | 175/350 | 205/400 | |

| Min/Max HP | 145/300 | 175/350 | 205/400 | 5,943 | 6,281 | 7,135 | |

| Total weight (kg)** | 5,704 | 5,942 | 6,659 |

* not EU homologated

** CTC -NS-hydr. brake 25 km/h; wheels 400/60x15.5; cross shaft CAT. III; reversible point 65-CTC; Lev. Disc (mech)-CTC; Actipack (knive) 565-F/T

Technical specifications

Technical specifications

Download brochureModel |

Working width |

No. of tines |

Min./Max. HP |

CTC 427 |

4.0m |

15 (spacing 270mm) |

145 / 300 |

CTC 420 |

4.0m |

19 (spacing 200mm) |

145 / 300 |

CTC 527 |

5.0m |

17 (spacing 270mm) |

175 / 350 |

CTC 520 |

5.0m |

23 (spacing 200mm) |

175 / 350 |

CTC 627 |

6.0m |

21 (spacing 270mm) |

205 / 400 |

CTC 620 |

6.0m |

29 (spacing 200mm) |

205 / 400 |

* not EU homologated

** CTC -NS-hydr. brake 25 km/h; wheels 400/60x15.5; cross shaft CAT. III; reversible point 65-CTC; Lev. Disc (mech)-CTC; Actipack (knive) 565-F/T