Optima TFmaxi

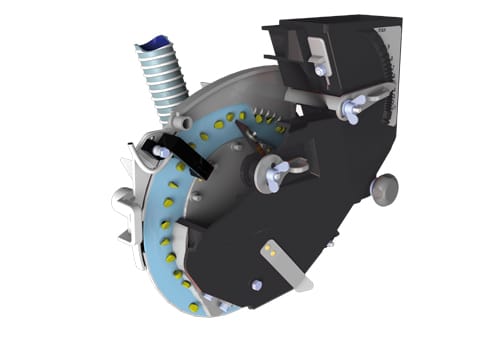

Seeder | Pneumatic precision drill

Large capacity combined with utmost precision

Pneumatic precision drill with a working width of 12m for best precision seeding and large capacity.

The advantages of this Pneumatic precision drill

- Most precise seed placement

- Maximum performance with 12m working width

- Fully integrated fertiliser spreader

- Fully ISOBUS-compliant

- 50 km/h transport on the road

Description

The Kverneland Optima is the universal pneumatic precision drill for maize, sunflowers, field beans, unpelleted beet, pelleted beet, dwarf beans, soya beans, peas, and many other types of seed. Within this product group, the Optima TFmaxi is the large capacity trailed model with a working width of 12m. It offers a unique performance with up to 100 hectare in one day – reducing the costs for the tractor and the driver.

The Optima TFmaxi is equipped with a 4000l fertiliser hopper and 16 HD-II rows with one central seed hopper optional with 1000l and seed hoppers volume of 60l each. Despite the large capacity, the pulling force is still low - starting from 240hp.

The Optima TFmaxi combines high performance technology with maximum user friendliness. The machine’s clear and logical layout together with the high level of intelligent technology offer the user maximum ease of use, from set-up and filling, to transport and seeding operation.

Kverneland Optima precision planter – accurate seed placement for every soil condition

The Kverneland Optima precision planter is designed to deliver accurate seed placement, ensuring maximum crop emergence and yield. Its advanced sowing units follow the ground contour perfectly, while the coulter forms a clean furrow for excellent seed-to-soil contact. The result: uniform crop establishment, consistent growth, and plant development.

Universal HD-II sowing row - built for all soil conditions:

The Optima TFmaxi is equipped with the universal HD-II row unit, making it suitable for a wide range for farming systems and soil types.

- Works on light to heavy soils

- Compatible with conventional and mulch seeding

- Provides optimal depth control even in extreme conditions

- Ensures effective ground contour following and precision seed placement

- Supplied with 60L seed hopper

This versatility makes the Kverneland Optima an ideal row crop planter for maize, corn, sunflower, sugar beet and other precision crops.

ISOBUS Technology for Smarter Farming

Modern agriculture demands more than just seed placement, it requires efficiency, cost savings, sustainability and precision farming tools.

The Optima e-drive II with ISOBUS connectivity integrates seamlessly with the Kverneland Tellus terminal. Using GPS and GEOCONTROL, each seeding element is automatically switched on or off at exactly the right moment. This eliminates overlaps and skips, ensuring every seed is placed with maximum accuracy.

Features

Features

For mulch and conventional sowing

- Optimal depth control even under extreme conditions, due to the heavy basic weight of the sowing unit with the possibility to add additional pressure (up to 100kg) onto each individual sowing unit via the spring-loaded system.

- Effective ground contour following, due to the large lateral depth control by open gauge wheels (Ø410mm, width 120mm).

- Precise seed placement by the small coulter which forms a clean furrow. Optional with quick-fit coulter tip to quickly exchange between standard layout for maize and the XHD coulter tip for sugar beet. Light re-compaction and seed covering is done by the intermediate press wheel (as option: heavy stainless steel) and the multi-adjustable V-press wheel – to ensure maximum field emergence.

Seeding heart without seals for HD-II

- The patented seeding heart by Kverneland has reduced maintenance costs to a minimum.

- No friction, no wear, low drive torque, minimum maintenance: The seed disc rotates in the seeding heart together with the vacuum chamber. This seeding drum is connected to the vacuum fan via a hollow shaft.

- This seed heart principal results in no loss of vacuum, and therefore a low vacuum requirement

- Stable design, modular system, low maintenance costs, high degree of wear resistance and optimum depth placement.

- For fertiliser placement Kverneland supplies hoppers for different applications.

- The chain drive for metering can be adjusted from 106 to 390kg per hectare at a distance between rows of 75cm.

- The fertiliser applicator is driven centrally by an easily accessible side mounted gear box.

- Fertilising coulter, standard seeding with narrow coulter design and stable, reliable construction, coil spring protection from sideways forces

- Mulch seeding notched double-disc coulter for blockage-free and precise fertiliser placement by a Ø 350mm notched double-disc Coulter.

GEOCONTROL - Cost saving with immediate payback

Seeding with GPS and GEOCONTROL in combination with an electric driven precision drill is a major step towards precision and cost saving. These machines are all equipped with ISOBUS technology which with the help of the IsoMatch Tellus terminal, can be easily controlled.

Each electric driven seeding element, in combination with GPS and GEOCONTROL, is automatically switched on or off in exactly the right place, ensuring there is no overlap with any row that has already been seeded. This is especially handy in triangular fields, on curved or irregular shaped headlands.

Precision Farming

Precision Farming

When deciding what equipment to purchase, it is not always easy to find the optimal solution in the broad market offering of today. Technology is developing fast and tractors and implements are more and more equipped with high tech electronics. We understand this complexity and are committed to provide you with easy farming solutions. Therefore these cost-efficient ISOBUS Universal Terminals, IsoMatch Tellus PRO and IsoMatch Tellus GO+ are made for easy machine control and efficient farming.

With its advanced hardware and software features, the IsoMatch Tellus PRO provides the optimal precision farming solution for an all-in-one control system inside your tractor cab.

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything a farmer needs to get the maximum out of his machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives the farmer the opportunity to view and control two machines and processes simultaneously.

Work easy. Be in control.

IsoMatch Tellus GO+ is especially developed for controlling the machine in a simple way. The farmer is in full control of the machine in exactly the way he wants. Easy set up the machine with the soft keys via the 7-inch touch screen. And, optimal control while driving, just use the hard keys and rotary switch. Controlling the implement has never been so easy.

This can be you your first step into Precision Farming

IsoMatch Tellus GO+ makes it easy to control any ISOBUS machine from your tractor cab. IsoMatch GEOCONTROL enables you to achieve higher yields, lower costs and do your work with less hassle. This licence key is divided in two parts, Section Control and Variable Rate Control, which are available from the IsoMatch Shop. Now you can buy the specific functionality that you need.

With manual guidance you are perfectly on track.

The IsoMatch InLine is a light bar which allows easy manual guidance. It is the perfect assistant to get you as close as possible to your desired A-B line. Mounted in the line of sight, you can easily see the distance from the A-B line and to which direction you should steer for the ideal position. The display of the IsoMatch InLine also displays the status of the machine sections, which adds more comfort of use. The LEDs can be dimmed for night operation.

SMART

Distance to A-B line with LED indication and a numeric display

EFFICIENT

Manual guidance in combination with IsoMatch GEOCONTROL

EASY

Displays status of machine sections

The essential accessory for IsoMatch GEOCONTROL.

The IsoMatch Global 3 is the GPS antenna, with DGPS accuracy, in the IsoMatch product range. It enables satellite navigation for site-specific section control, variable rate application, manual guidance and field registration.

SMART

Allows manual guidance, automatic section control and variable rate in combination with IsoMatch GEOCONTROL

EFFICIENT

DGPS accuracy without additional subscription fees

EASY

Easy to fit with mounting brackets included

Connect to a local wireless network on your IsoMatch Tellus.

IsoMatch Wireless (USB-stick) is complementary to the IsoMatch Tellus and makes it easy to connect to a local wireless network, such as your phone’s hot-spot, home network etc.

No additional costs of an internet service provider. When connected via the IsoMatch Wireless you can browse the internet, view the weather, Gmail, Google, etc.

The IsoMatch Eye is the camera option in the IsoMatch product range.

IsoMatch Eye is a camera that has been developed for use with our sophisticated IsoMatch Tellus GO+ and IsoMatch Tellus PRO dual screen terminal. The IsoMatch Eye is switchable from rear view to standard view.

It gives you full control and overview of entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety e.g. when reversing the machine or manoeuvring around obstructions.

SMART

Changeable from rear view to standard view

EFFICIENT

Full control and overview of entire machine operation

EASY

Night vision by integrated LED’s

IsoMatch MultiEye is an accessory for connecting multiple cameras to the IsoMatch Universal Terminal.

With the IsoMatch MultiEye you can connect multiple cameras to the IsoMatch Tellus PRO or IsoMatch Tellus GO+ Terminal. You can easily switch between the cameras without the need for an additional screen in you tractor cabin. It gives you full control and overview of the entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety when reversing the machine or manoeuvring around obstructions.

SMART

You can connect up to four IsoMatch Eye cameras and easily switch between the cameras with the remote control box which is standard included.

EFFICIENT

Full control and overview of entire machine operation from every side you want.

EASY

Night vision by integrated LED’s which increases the safety when reversing the machine or manoeuvring around obstructions.

Made for smart, efficient and easy farming

IsoMatch GEOCONTROL is an advanced software application within the IsoMatch Tellus PRO and IsoMatch Tellus GO+ that helps you to control all ISOBUS compatible Kverneland Group machines such as sprayers, spreaders and seeders! Combined with a GPS receiver it fulfils the future needs in terms of easy, smart and efficient farming!

GEOSEED increases the yields of row crops and ensures maximum efficiency. Seeds are placed perfectly in line and in relation to each other.

GEOSEED is offered in two different levels:

GEOSEED Level 1 is the synchronization in the machines working width. This improves the distribution of seeds up to perfection in parallel or diamond pattern: Positive effects are the best use of nutrients, water and sun. Also the wind and water erosion is decreased.

GEOSEED Level 2 is the synchronization in the whole field. This is the necessary requirement for interrow cultivation, also across the seeding direction. GEOSEED is the only system in the world, that makes this mechanic weeds control possible!

Technical specifications

Technical specifications

Download brochure| Model | Optima TFmaxi | |

|---|---|---|

| Frame type | trailed fold | |

| Working width (m) | 12.00 | |

| No. of HD-II sowing rows | 16 | |

| Row width HD-II row (cm) | 70-80 | |

| Central seed hopper (l) | 1,000 | |

| Transport width (m) | 3.00 | |

| e-drive, ready for GEOCONTROL | Standard | |

| Fan drive 1000rpm | Standard | |

| Hydraulic fan drive | Option | |

| Linkage | CAT III N Crossshaft | |

| Tyres 12.5/80-18 | Standard | |

| Hydraulically operated track marker | Standard | |

| Mounted fertiliser spreader | Option | |

| Maximum no. of rows with mounted fertiliser spreader | 16 | |

| Electro-hydraulic drive of fertiliser spreader | Standard | |

| Fertiliser hopper capacity in litres | 4,000 | |

| Filling auger | Option |

Technical specifications

Technical specifications

Download brochureWorking width / transport width |

12.00m (75cm) / < 3.00m |

Transport length / transport height / transport speed |

9.80m / 3.48m/ 50km/h (max. transport loading 2 t) |

Row width |

70cm, 75cm, 80cm |

Working wheels and transport wheels |

6 x 12.5/80 and 2 x 560/60 |