iM Farming

Smart solutions that make tough and demanding conditions less complicated and support you towards a profitable way of working

Smart Easy Efficient

Our precision farming offering is essential in managing your business with success. Applying electronics, software, satellite-technology, online tools and big-data enables you to use your equipment more effectively and reach higher profitability of your crops.

We offer you numerous options and solutions for how to produce more with less; utilize inputs more efficiently and thereby increase profits and sustainability.

Hydraulic drive boosts spreader accuracy

For Alex Hastie & Co, weigh cells and section control have boosted fertiliser application accuracy at the 550-acre Dolphingstone Farm, Tranent, East Lothian. A succession of Kverneland weigh-cell spreaders have performed well for the family farm, with the reference sensor and section control delivering unprecedented accuracy on sloping fields.

But when working on steep slopes, the Hasties have recently noticed that disc speed could be compromised from a fluctuation in tractor revs.

“We use 180hp tractors, which is an ideal size for us – not too big and clumsy in our 24m tramlines, but powerful enough for most jobs,” says Iain Hastie. “But I’ve noticed that on our steepest fields, a drop in engine rpm as the tractor climbs the steeper parts of a field has caught us out when fertiliser spreading. And it’s the only area where we could use more power.”

“A lower gear does help, though the trade-off is then less output,” says Iain. “What I really wanted, was a Kv spreader with hydraulic drive, so we could set the disc speed independently of tractor revs.”

His investment this year in the very latest Exacta TL GEOSPREAD with iDC (intelligent Disc Control) is the solution he sought, and he’s delighted with its performance.

“It’s now absolutely superb,” says Iain. “We could never fault the precision of GEOSPREAD section control, or the spreading accuracy on shallower slopes. We tray test too, and invest in quality fertiliser, to make sure we do the best job we can.”

“Eliminating the pto shaft has brought several benefits,” says Iain. It has unlocked the full potential of spreading performance for us; it’s also saving on fuel by running at lower revs most of the time; and it has improved operator safety.”

“And we no longer have to use an uphill speed and a downhill speed, when spreading on the steeper fields.”

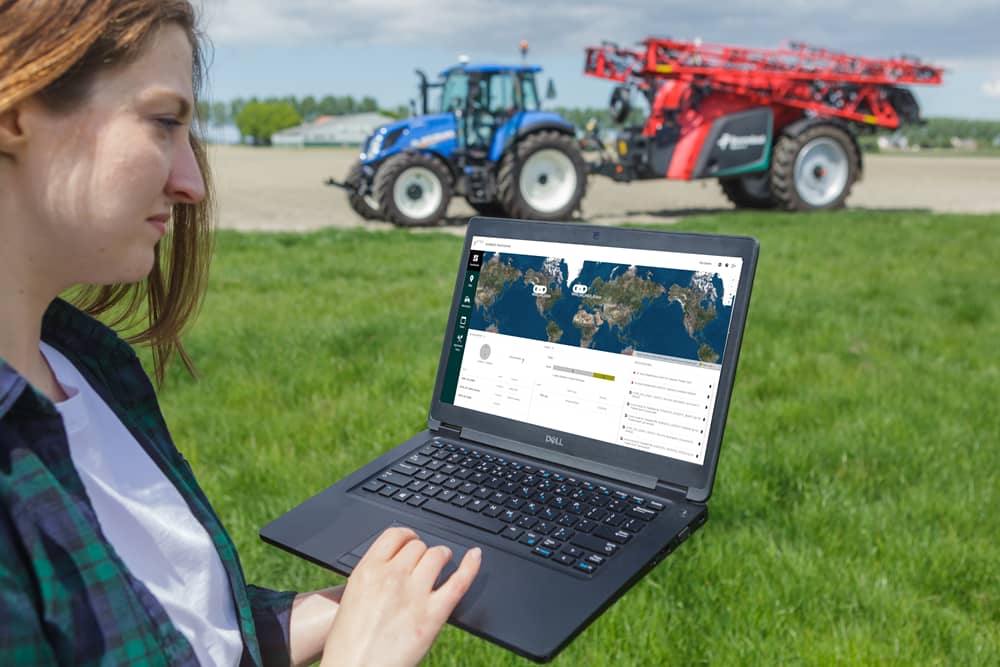

IsoMatch FarmCentre is a wireless telematics solution for machinery optimisation and fleet management, suitable for all Kverneland and ISOBUS machines. IsoMatch Tellus PRO or IsoMatch Tellus GO+ become the gateway to connect machines to the cloud and consequently, allow a user’s device to control the fleet in real-time, send and receive tasks from the implements, receive alerts and analyse the collected data in pre-defined reports. All these features are included in an easy-to-use intuitive web application that works with any smart device like a laptop, tablet, or phone. IsoMatch FarmCentre also contains an exclusive Agronomic Tools module to integrate external software on demand such as FMIS like MyDataPlant.

Individual nozzle control to eliminate overlaps, greater boom stability and a wider boom were all on the wish-list for Wayne Dye, when the time came to replace his 4,000-litre self-propelled sprayer.

“I wanted the very latest in application technology, along with more output and capability,” says Wayne of Long Sutton, Lincs-based DE Dye & Son. “So we bought the highest specification trailed sprayer we could find – and our search led us to the Kverneland iXtrack T4 from Irelands Farm Machinery. Nothing else compared to it with price and specification, and the dealer back-up is second-to-none.”

Wayne (pictured, centre), along with his son Alfie and his father Derek, grow a combination of cereals and potatoes from Brown’s Gate Farm. The wider boom was bought for more output.

“We had been spraying our potatoes at 82in centres with a 27m boom, but using a contractor for cereals at 72in centres on 36m tramlines, to make the most of timings,” he explains. “Now we can standardise our tramlines at 82in centres.”

With individual nozzle control, overlaps are not a problem. He reports that one 12-acre field with 11 corners, is saving the equivalent of one acre of overlap thanks to individual nozzle control.

“None of our fields are square, so we’re expecting quite a saving across the farm with our chemical costs over the year,” he says. “And we’ll be producing far better crops as a result.”

Complete with 4,600-litre tank and 36m boom, he says sprayer specification is impressive with iXspray software, iXclean Pro one-touch rinsing, Boom Guide Pro, IsoMatch Grip programmable joystick, steered and suspended axle, drawbar suspension, boom line recirculation and a two-year warranty.

And the switch to a trailed model has made use of available tractor power – a four-cylinder Fendt 516, which has been fitted with a Tellus Pro dual screen universal terminal, alongside the Vario terminal.

“Adding the IsoMatch Tellus PRO makes so much sense,” he says. “I can watch the sprayer functions on the top part of the screen, and the application map on the lower part. It’s a superb combination that compliments the tractor screen, and I can use it with my e-drill Maxi power harrow drill combination.”

Wayne says the attention to detail with the sprayer also stands out.

“I like the way the induction hopper is protected from dirt and debris when closed; the boom sensors automatically fold with the boom for added protection; you can move precise amounts of water from the clean water tank, and using autofill, you’ll always get the tank contents correct for the area being sprayed. It’s brilliant.”

“Not only is the sprayer easy to use and extremely accurate, it’s also aesthetically pleasing and modern-looking too,” he says. “It’s a future-proof purchase that is delivering cost savings and efficiency for us, and to assist Alfie who will eventually take over the business. I wish we’d bought one sooner.”

Stress-free spraying

When replacing his 10-year old mounted sprayer, David Jackson looked at many options to find a future-proof solution that would improve output and efficiency at the 300-acre Little White Farm, Brancepeth, County Durham.

“I swapped a 120hp tractor and 1500-litre mounted sprayer for a 185hp Puma, then looked for a front and rear tank combination,” explains David. “I thought adding a front tank would be better than just carrying a one tonne weight.”

His research resulted in a Kverneland iXter B18 with iXtra front tank supplied by local dealer Paxtons, giving a total carrying capacity of 2,900-litres.

“It’s a heck of an improvement in logistics, and is similar to a small self-propelled sprayer, but for much less cost,” he says.

Sprayer specification includes auto start-stop for nine sections on the 24m boom, plus iXclean Pro one-touch tank washing and electric valve management, with control through a IsoMatch Tellus PRO dual screen terminal.

“The sprayer is so clever that I now put a tramline around poles or obstructions, and treat them like a headland,” he says. “The sprayer takes care of the rest. And with GPS, it’s really good on grass fields without tramlines.”

He says liquid transfer is evenly balanced, providing good stability on slopes.

“I’m really impressed with the sprayer, and I really like the vertical folding boom – it keeps nozzles away from the cab,” he says. “It mixes easily, washes out effortlessly and it has given me much more precision and output, without having to rush around.”

“It’s important with anything I do that I enjoy it as much as possible – and with this set-up, putting on sprays and liquid fertiliser is no longer a chore,” he adds.

Learn more about IsoMatch GEOCONTROL and how you can benefit from using it!