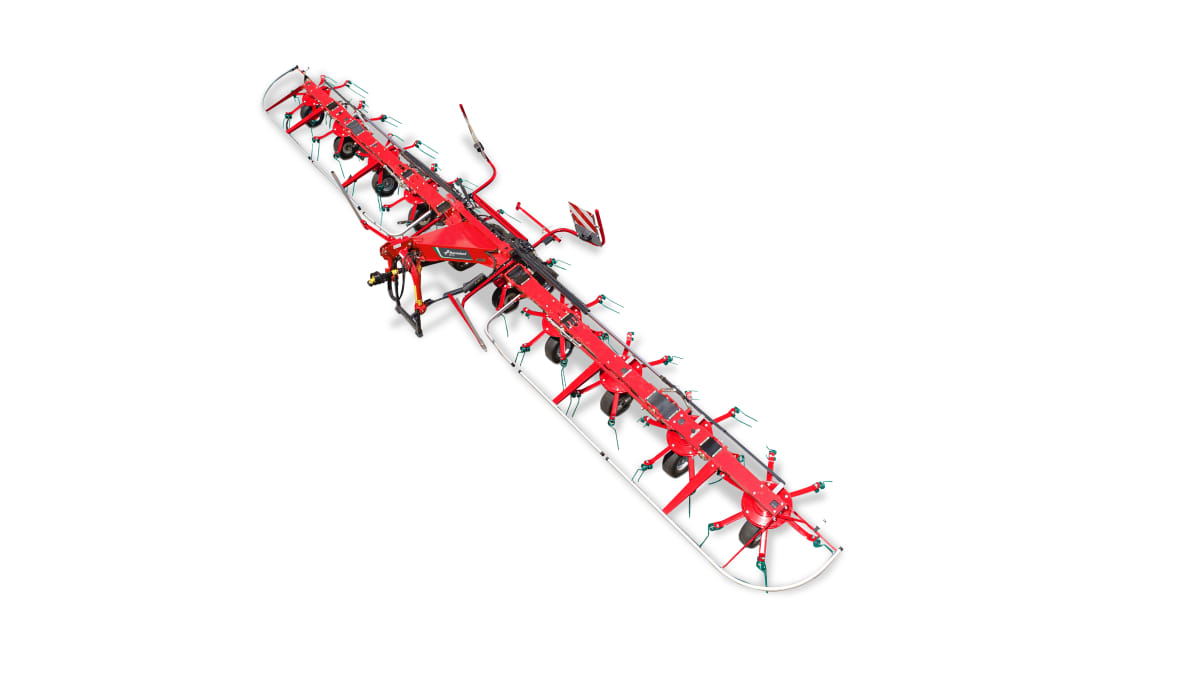

Kverneland 85112

Tedder | 3pt mounted Tedder

Productivity at the core

Heavy duty mounted tedder with compact transport dimensions

The advantages of this 3pt mounted Tedder

- Maintenance-free in season, except PTO and carrier

- Transport running gear for smaller tractors

- Flexible HexaLink finger clutch on outside rotors

- Optional electric comfort control

- Central hydraulic adjustment for border tedding

Description

Kverneland 85112, with 11.2m working width, is designed to perform perfectly in all crop conditions, with a minimum of non-productive maintenance required and with diminished transport dimensions. Featuring a heavy-duty fully closed headstock this machine will fit perfectly into the operation of professional farmers, looking for a strong, effective, and versatile tedder. This tedder is fitted with a high performance driveline combination. The complete driveline is maintenance-free, and offers highly reliable transfer of power, combined with extremely compact transport. Thanks to highly flexible frame design the machine has ideal adaptation to ground contours.

Highlights

- Fully maintenance free in season, except PTO.

- Strong driveline combination with maintenance-free u-joints and HexaLink finger clutch

- Strong and sturdy design with closed V-shaped central unit.

- Central adjustment for border spreading keeping the crop inside the field.

- Largely dimensioned oscillation dampers for excellent running characteristics.

- Optional headland kit for easy lifting on headlands.

Features

Features

Powered by a maintenance-free driveline and gearboxes, focus can be directed towards the essentials to maximise productivity. No time is wasted on time consuming greasing. Additionally the hinges are connected with strong maintenance-free roller bearings for extended longevity and stability of the connection points.

- Transport position with weight on the transport carrier allows for using small tractors down to app. 70 hp

- Large wheels on the carrier 10.0/75-15.3 with an outstanding wide track of 2.45 m ensure excellent and stable track following and smooth running characteristics

Electro-hydraulic Control of main functions with simple Joystick (optional).

Technical specifications

Technical specifications

Download brochure| Model ProLine | 85112 | |

|---|---|---|

| Working width (m/ft) | 11.20 / (38’8”) | |

| Number of rotors | 10 | |

| Number of tines/rotor | 6 | |

| Transport width (m/ft) | 2.94 / (9’8”) | |

| Transport length (m/ft) | 2.16 / (7'7") | |

| Storage height (m/ft) | 3.80 / (12’6”) | |

| Capacity theor. (ha/h) | 9.0 |

Technical specifications

Technical specifications

Download brochureWorking Width |

Rotors/Tines |

Weight |

|

8590 C |

9.00m |

8/6 |

1700kg |

85112 C NEW |

11.20m |

10/6 |

2225kg |