Be prepared for the coming season - by giving your Kverneland Disc Harrow a health check and ensure that you have sufficient stocks of essential wearing parts. Your local Kverneland dealer is standing by to assist you in any way needed to get safely through the season with minimal downtime.

MAINTENANCE TIPS & TRICKS

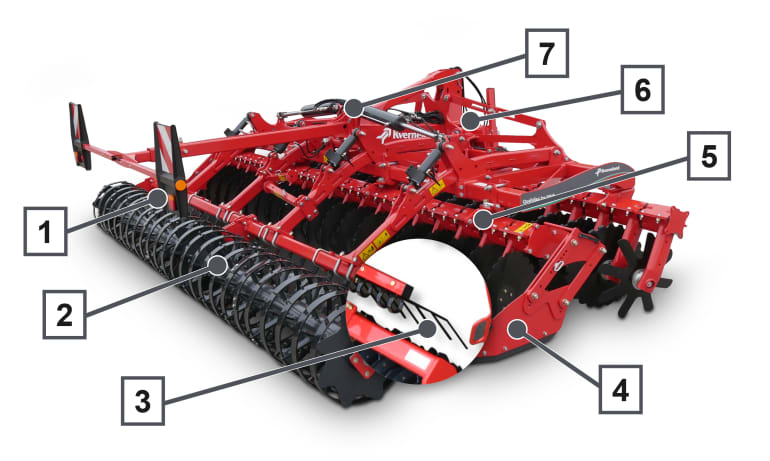

Overview

We have put together a checklist to go through to make sure your Kverneland Disc Harrow is ready for the upcoming season and will perform at maximum capacity.

Lights

Ensure that lighting is working correctly (rear and front if equipped).

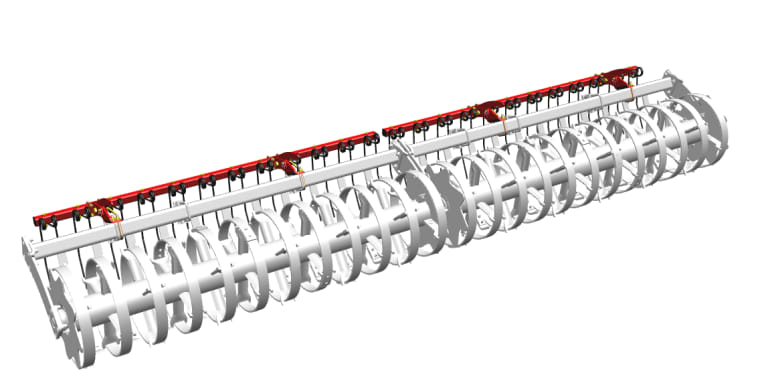

Roller

Inspect wearing parts and bearings on the roller.

Fingers

Check fingers at levelling and following harrows (length, not bent or broken).

Deflector

Ensure that deflectors work properly and replace wearing parts if necessary.

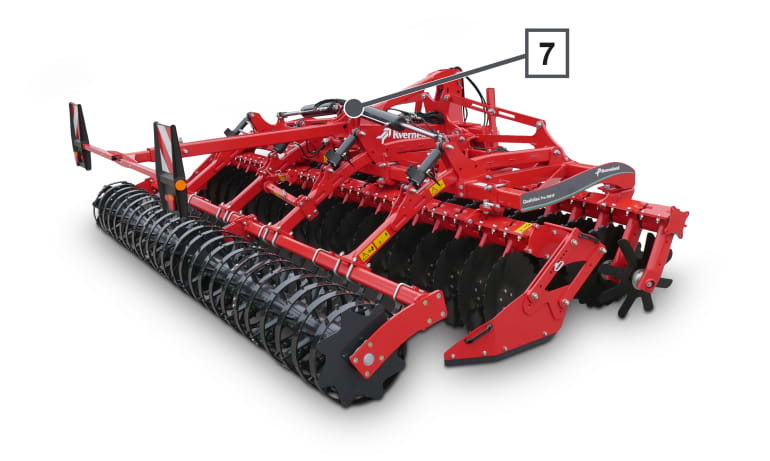

Lateral Adjustment

Check disc overlap to ensure a perfect cutting quality.

Easy to adjust

As the disc is wearing down and the disc diameter is reduced, Qualidisc Pro can be adjusted to compensate and maintain optimal cutting quality. Lateral adjusters are located at the bar over the discs. Measure the disc diameter and adjust according to numbers indicated on the sticker.

See the operation manual for detailed instructions.

1. Find the correct setting on the sticker.

2. Adjust with adjustment bolts.

3. Notches indicate the different settings.

Discs & hubs

Check discs for wear and ensure that they turn correctly.

Maintenance-free bearings

Make sure to refit with Original Kverneland disc hubs to maintain an optimal working machine. The hubs are fitted with high quality maintenance-free double ball bearings, exclusively developed for extreme soil conditions and designed to withstand heavy loads.

Bearings are well protected against dust and water to minimize wear.

Hydraulics

Check hydraulic systems (depth, folding, lifting).

ORIGINAL PARTS - USEFUL INFORMATION

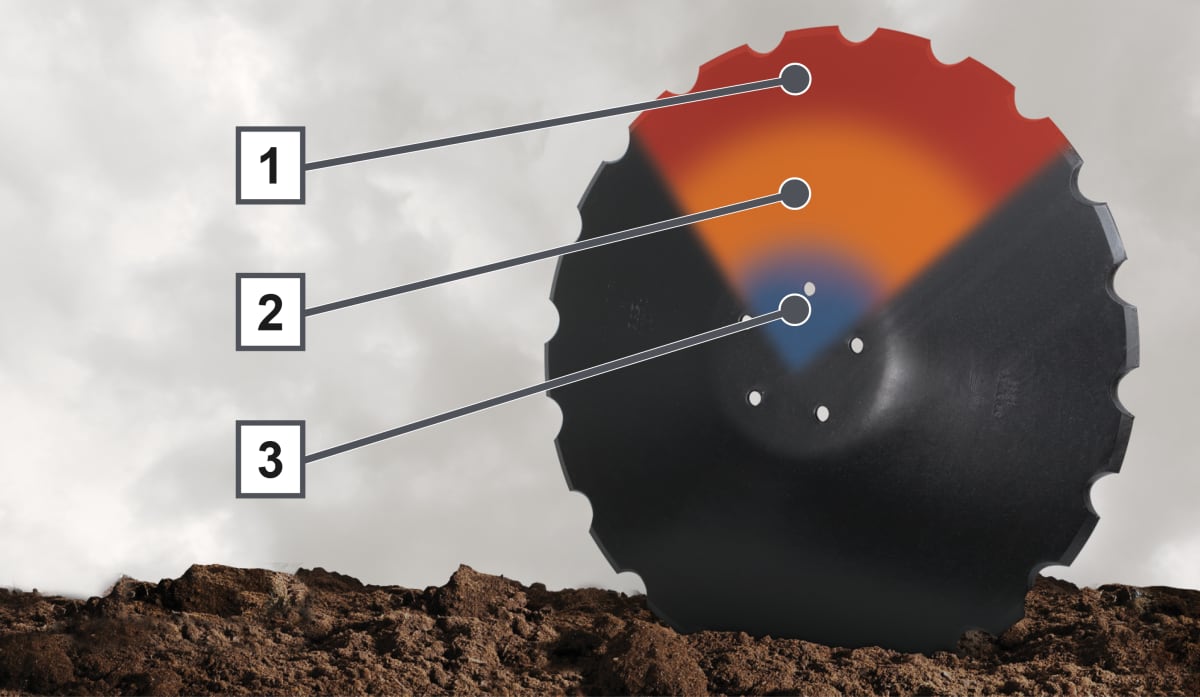

HEAT TREATED FOR COST EFFICIENCY

1. Diamond hard zone to protect against wear.

2. Mix between flexible and hard zone.

3. Flexible zone to protect bolt holes.

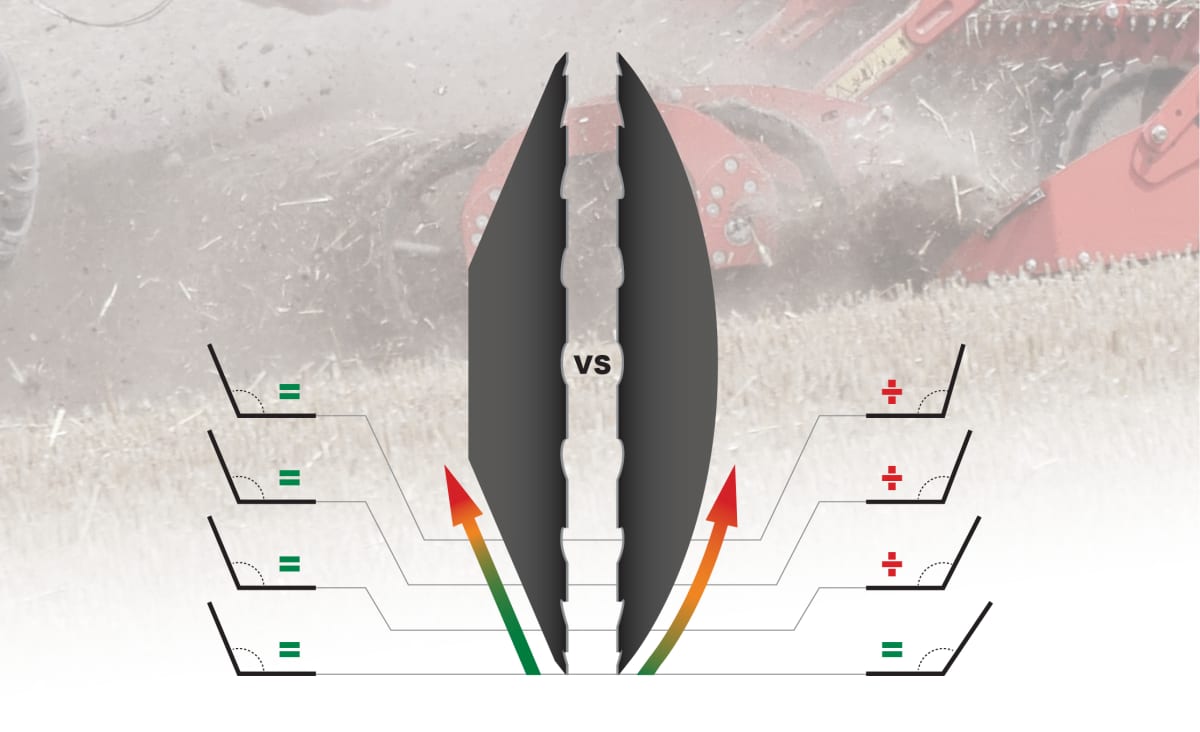

THE ADVATAGES OF CONICAL DISCS

KVERNELAND CONICAL DISC

The conical disc will ensure a constant cutting angle

throughout the lifetime of the disc.

CONVENTIONAL ROUND DISC

Round discs will have an altering cutting angle as the disc wears down.

STAR DISCS

STAR DISC - RIGHT

Diameter 600 mm

A135819997

STAR DISC - LEFT

Diameter 600 mm

A135820097

NOTCHED DISCS

CONICAL DISC

Diameter 600 mm

Thickness 6 mm

A135419697

CONICAL DISC - BIG SCALLOPS

Diameter 600 mm

Thickness 6 mm

A135450297