Prepare your Kverneland Flail Chopper for peak performance with a quick pre-season check. Ensure it’s ready to operate at full capacity for a smooth and efficient season ahead!

MAINTENANCE TIPS & TRICKS

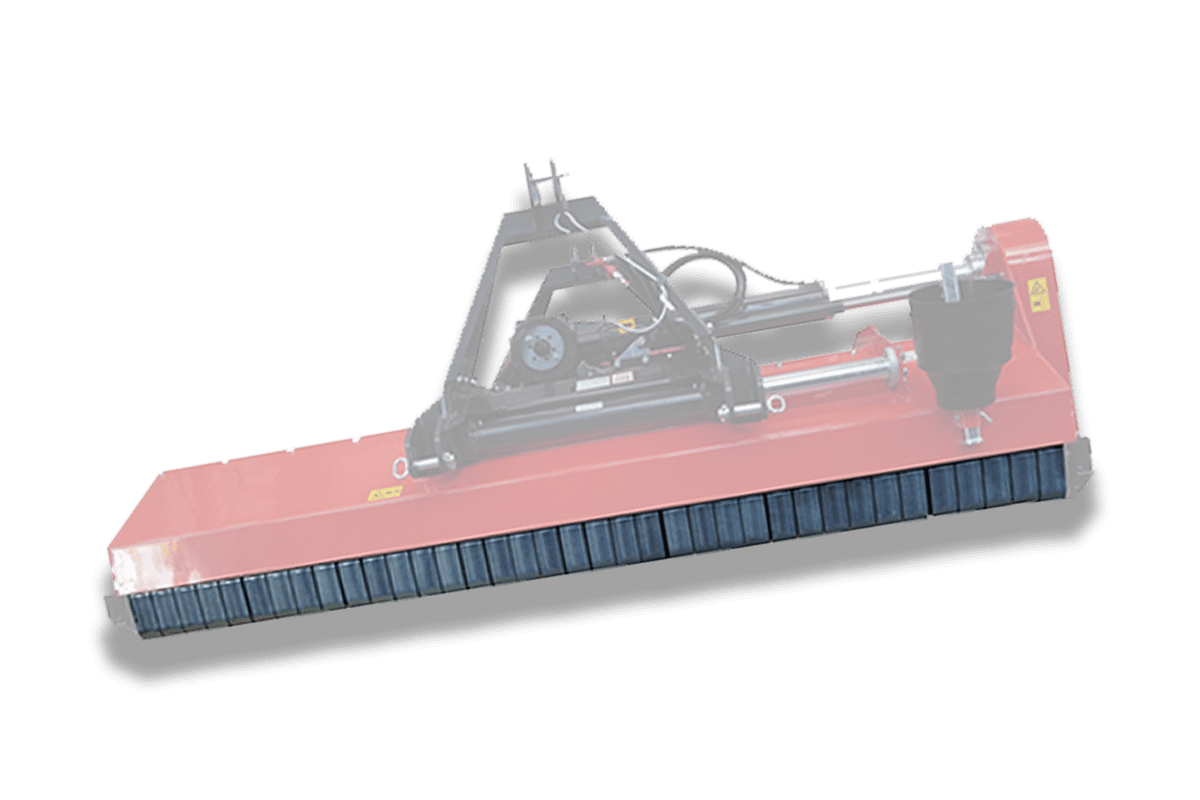

Overview

We have put together a checklist to go through to make sure your Kverneland Flail Choppers is ready for the upcoming season and will perform at maximum capacity.

Belts and Pulleys

Your Flail chopper is driven by five VX type V-belts running on invertible pulleys which allows adaptation for 540 or 1000rpm drive. Replace them in case they present frays or they are consumed

Oil level

Check oil level on gearbox.

Fastening screws

Regularly check the fastening screws for the main components. Do not hesitate to replace the back deflector in case of evident damages.

PTO drive

Inspect PTO drive shaft and its protections between tractor and machine.

Replace them if damaged.

Bearings

Periodically check bearings on rollers to detect ay warning signs before eventual field stops.

Rotor blades

Check rotor blades or hammers for damages or wornout which directly impact chopping performances and rotor balancing (vibrations).

Greaser pin

Grease all the components fitted with greaser pin.

ORIGINAL PARTS - USEFUL INFORMATION

PERFECT WORKING HEIGHT

Correct adjustment and setting of either the ground following wheels or full width roller according conditions (chopped material and type of ground) would maximize the chopping effect as well as preserve the key elements of your flail chopper from premature wear of damages.

BOLTED DOUBLE SKIN & COUNTER KNIFE

Under constant stress and after several hectares and working hours, both items suffer and need to be replaced to maintain the full chopping efficiency. Check their status and get in contact with your local dealer in case of doubt or to have him ordering the right part!

STONE GUARD FLAP

MAY040035.61 - MAY010028Y

Safety being one of the core values for Kverneland, a missing flap or a damage that compromise its functionality, must be replaced to avoid risk of injury by projections.

SKIDS

MAY0400011.86 - MAY0400012.86

To correctly follow the soil profile, to keep high machine performance, prevent wear and inefficient power consumption, it is important to carry correct skids adjustments or replace the wearing element in case they present tear.

Universal blades & Paddle

MA7800080 - MA6400077

MAY020012 - A137177700

MAY030023 - A137177600

MAY010016 - MAY010020

MA6200080

Cup & Rock Blade

MA6200077

MA5200078

MA6200078

Hammers

MAY010019 - MA6303076

MAY020011 - MAY020011

MAY030002