Be prepared for the coming season - by giving your Kverneland baler a health check and ensure that you have sufficient stocks of essential wearing parts. Your local Kverneland dealer is standing by to assist you in any way needed to get safely through the season with minimal downtime.

MAINTENANCE TIPS & TRICKS

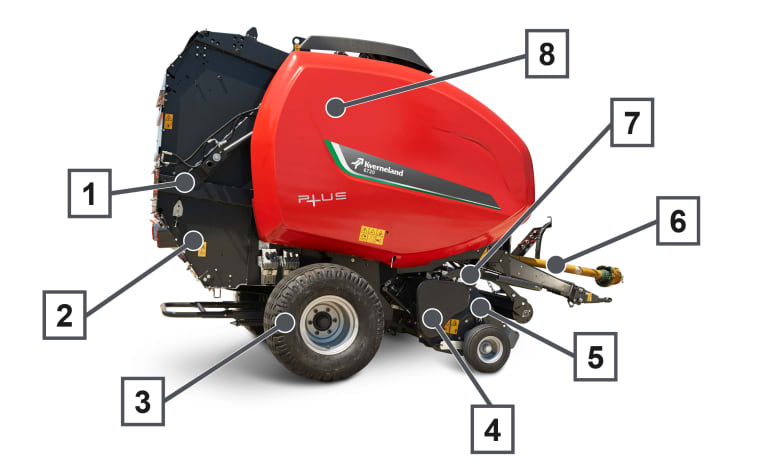

Overview

We have put together a checklist to go through to make sure your Kverneland Baler is ready for the upcoming season and will perform at maximum capacity.

Belts

Inspect the belts for potential frays that need to be repaired.

Perfectly working belts are essential to produce good bales. You should always make sure that your belts are not frayed, that they have the

correct tension and are tracking well under operation.

Original Kverneland belts areproduced under strict standards an will always ensure that your baler works as intended.

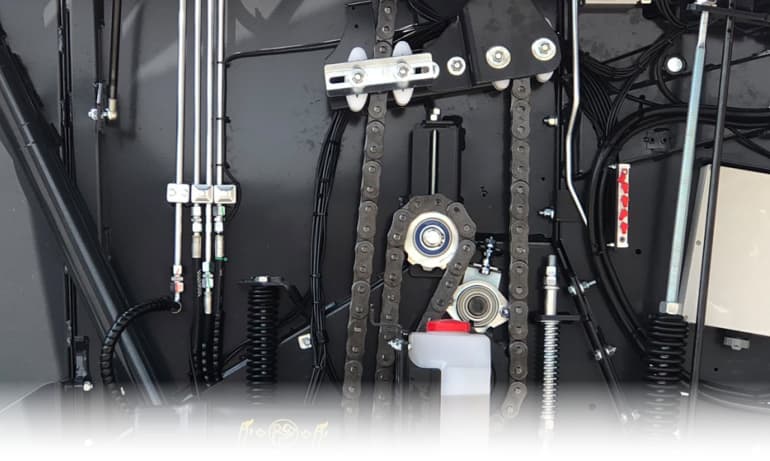

Transmission Chains

Adjust all transmission chains. Check for wearing and oiling points.

Over time chains will expand in lenght and need to be replaced. A worn or damaged chain will quickly start wearing down cogs, pins and sprockets.

A fresh and well operating chain will secure your Kverneland baler and ensure safe and efficient operation.

Tires

Check tire pressure and tightness of the wheel studs.

Chain Tension

Check and adjust the chain tension of the pick up unit.

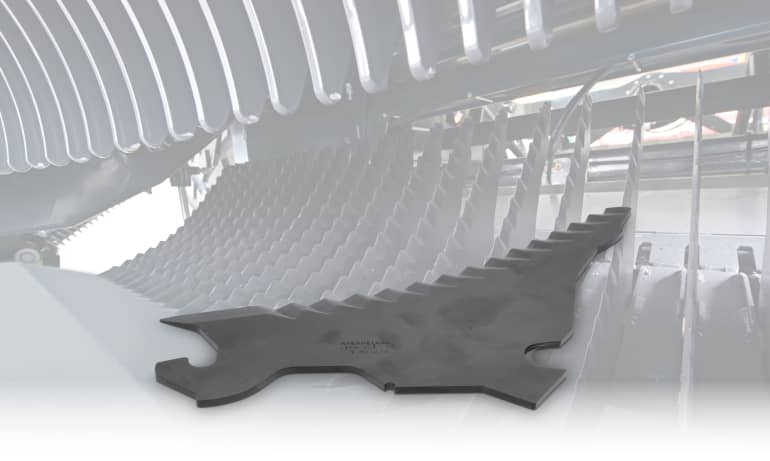

Tines

Check tines and protections from pickup. Replace if worn or damaged.

To avoid any leftovers in the field, our tines are high performing and long lasting in the toughest conditions.

PTO shaft

Check PTO shaft and guards for wear and correct operation. Lubricate PTO shaft.

Cutting knives

Check cutting knives. Replace if worn or if thread is considerably reduced.

Well operating knives ensure a smooth crop cut. Original knives are made of high quality steel to stay sharp.

Oil levels

Check oil level on the centralised lubrication system tank.

ORIGINAL PARTS - USEFUL INFORMATION

Flares

Flares are essential for perfect pick-up performance. Original flares prevents product residue from clogging inside the pickup.

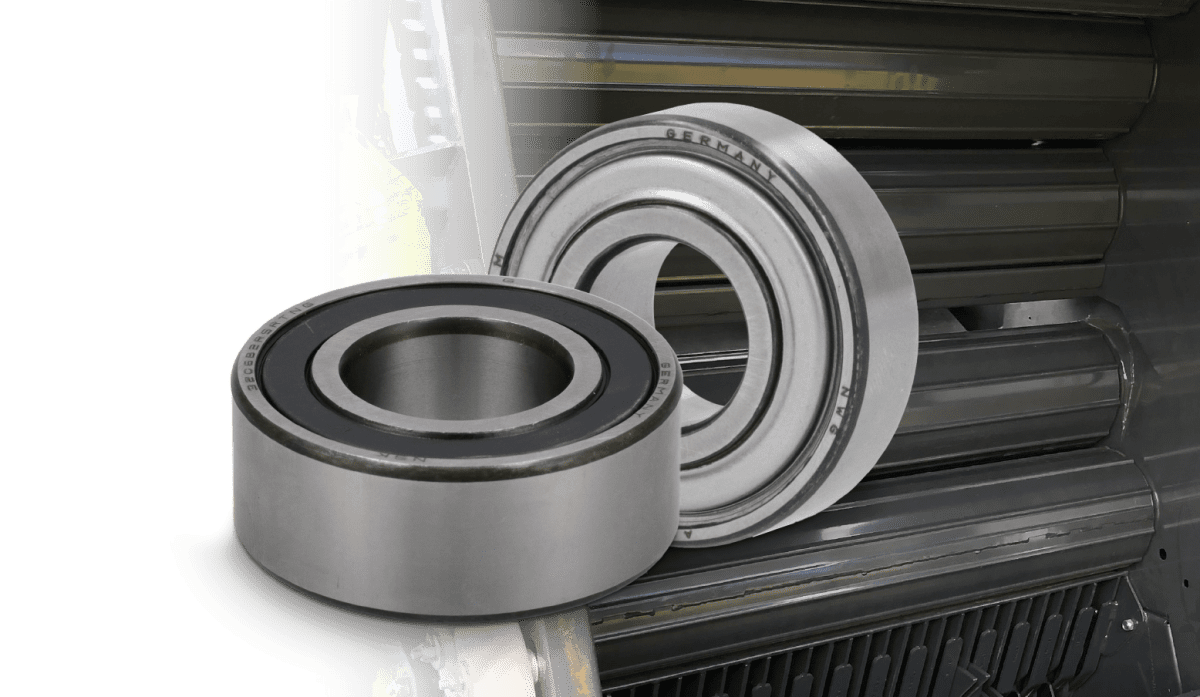

BEARINGS & ROLLERS

It’s important to periodically grease the bearings inside the chamber. This will prevent breakage and overheating during baling.

Check the roller axles for play, which is an indication of broken bearings that needs replacement. Original Kverneland bearings are carefully selected to operate optimally under load with maximal lifetime.