Kverneland 6500F

Baler | Fixed Chamber round baler

High-Performance Fixed Chamber Balers

PowerMax full roller fixed bale chamber with a bale diameter of 1.25m

The advantages of this Fixed Chamber round baler

- 2.3m extra wide pick-up for increased intake speeds

- ChopFeed -15 knife pre-chopping system and PowerFeed rotor

- PowerMax bale chamber with 18 ribbed profile rollers

- Patented PowerBind net system

- Intuitive control with the Focus 3 & ISOBUS terminal

Description

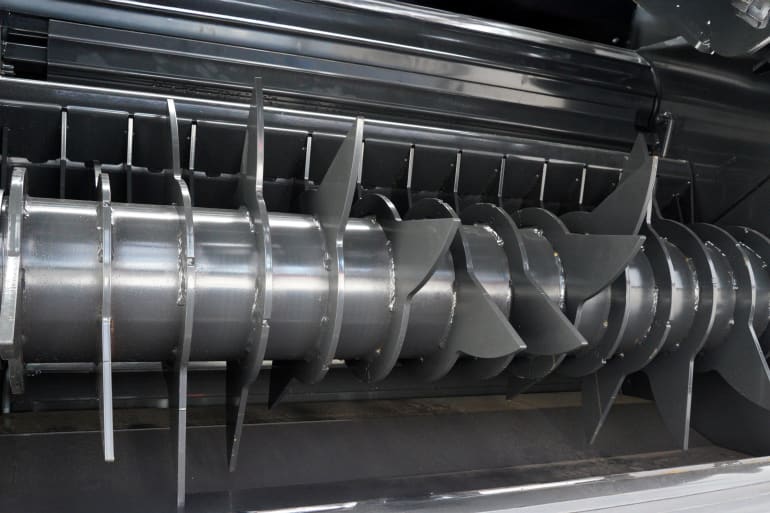

Kverneland 6500F is the specialist baler for heavy silage conditions. The bale chamber is formed by 18 ribbed profile rollers, which ensure maximum bale density and superb bale rotation in all conditions. At the same time, the power requirement is kept to a minimum for more efficient operation.

Highlights

2.3m extra-wide low profile pick-up with roller crop press provides clean raking performance and increased intake speeds

ChopFeed15 knife pre-chopping system and the PowerFeed rotor provides superb intake performance in all crops

Parallelogram Drop Floor system with the optimised profile for smoother crop flow & increased clearance

Patented PowerBind net system for fast and reliable net binding

PowerMax bale chamber with 18 ribbed profile rollers designed for wet silage and providing high-density well-shaped bales

Simple and intuitive control with the Focus 3 terminal and optional Isobus configurations

Features

Features

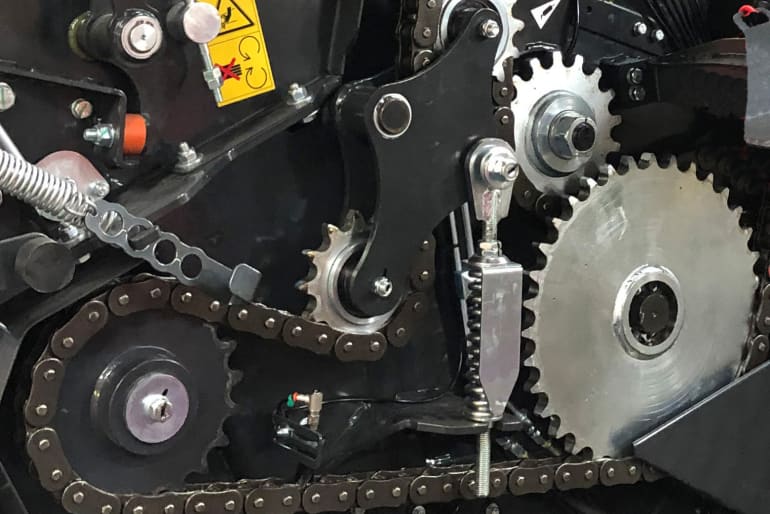

- The one piece integrated input gearbox ensures long life time and requires minimal horsepower.

- Our intake rotor and all bale chamber drives are equipped with heavy-duty 1¼” pitch chains, ensuring durability and high performance.

- Extended service life thanks to the 50mm diameter bearings at both ends on the baler chamber rollers.

The 2.3m pick-up is packed with advanced upgrades for superior crop handling and durability:

- Five-Tine Bar System – Features 32 tines per bar for optimal crop gathering and efficiency.

- Reinforced Stability – Each tine bar is supported by four ball bearings for smoother operation and extended lifespan.

- Precision Cam Tracks – Twin easy-access cam tracks at both ends ensure seamless performance and maintenance.

- High-Capacity Roller Crop Press – Large diameter design enhances intake speeds for improved efficiency.

- Compact Inboard Driveline – Reduces transport width, offering better maneuverability and ease of transport.

ChopFeed 15 Chopping system

The ChopFeed 15 knife pre-chopping system enhances operational efficiency and ensures smoother crop flow into the baler. Its specially profiled knives are designed to deliver a consistent chop length with minimal power usage. With a chop length of 70mm, it is the perfect solution for creating tight, dense bales. These bales improve fermentation, offer easier feeding out, and minimize wastage.

Individual Knife Protection

Each knife in the ChopFeed 15 is individually spring-protected against foreign objects, providing superior protection compared to systems that only shield the entire knife bank. This innovative design ensures greater durability and reliability.

PowerFeed Rotor Intake

The PowerFeed Rotor Intake system is designed to deliver impressive intake capacity, effortlessly handling all crop types, no matter the conditions. Its large intake rotor diameter ensures the system can manage even the toughest harvest conditions with ease.

The ChopFeed 15 and PowerFeed intakes system feature the highly efficient Vicon Parallelogram drop floor system, designed for quicker and easier blockage clearance. Unlike traditional systems that only lower the rear edge, this innovative design also lowers the front section of the floor, where blockages are more likely to occur, ensuring faster, more effective clearing.

The Kverneland 6500F is the ideal baler for heavy silage conditions, built to handle tough tasks with ease. Its PowerMax bale chamber features 18 heavy-duty rollers arranged in a perfect circle, ensuring maximum bale rotation capability in all conditions. This design guarantees the production of well-shaped, dense bales, consistently achieving high density in both wet and dry materials. Two rollers in the lower section of the main bale chamber help distribute the load, reducing stress and extending the baler's lifetime

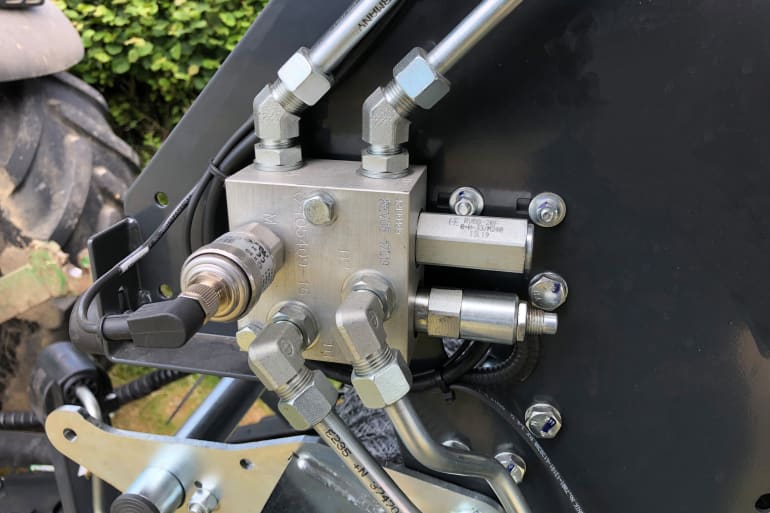

Adaptable Bale Density

For ultimate flexibility, the bale density is hydraulically controlled and electronically monitored, allowing for precise adjustments from the comfort of the tractor cab. This feature lets you tailor the bale density to suit the prevailing crop conditions for optimal results.

Kverneland 6500F eatures the patented front-mounted PowerBind net system, eliminating the need for troublesome feed rollers. With its market-leading cycle time, PowerBind ensures faster, more efficient baling, making your operation smoother and more reliable.

The PowerBind net system continuously retains the net in the injection arm. As the bale nears completion (90%), the arm moves forward, preparing for net injection. Once the bale is fully formed, the net is fed directly onto the bale at a flat angle, keeping the net tight and ensuring precise, reliable application every time. With PowerBind, you can confidently achieve professional results, unaffected by wind or crop build-up.

Low Net Loading Height

PowerBind features an exceptionally low net loading height, providing maximum convenience and efficiency. Replacing an empty roll is quick and easy—simply swing out the shaft and slide on a new roll.

TIM (Tractor Implement Management)

TIM is an ISOBUS solution that enables cross-product and cross-manufacturer communication between tractors and implements. This system allows for seamless two-way communication, ensuring both machines work in perfect harmony. By automating many repetitive tasks, TIM not only boosts efficiency but also reduces the risk of human error caused by fatigue. This technology enhances driver comfort by taking over numerous manual actions during the baling process.

Cost Efficiency

Another important factor to consider is cost. Utilizing a TIM-equipped baler efficiently can significantly reduce expenses related to wear and tear on parts.

TIM system as optional equipment

TIM simplifies the baling process by taking the majority of the workload off the operator's hands. This results in a significant increase in operator comfort, as it eliminates many repetitive tasks. With reduced fatigue, work can be completed faster while maintaining consistently high bale quality. The TIM system is highly user-friendly, allowing even operators who change frequently to quickly master its functions and seamlessly integrate it into their workflow.

Focus 3 Control

The Focus 3 is built for effortless operation, with all essential functions easily controlled from the terminal. These include:

- Bale density adjustment

- Net quantity adjustment

- Tying information during the binding cycle

- Manual or automatic binding selection

- Five daily bale counters and a total bale counter

- Selection of knives, drop floor, or pickup raise/lower function

With these user-friendly controls, the Focus 3 optimizes your baling process, ensuring greater efficiency and precision at every step.

The automatic greasing reduces the daily maintenance and increases the reliability through continuous greasing.

Kverneland Sync for Balers – Real-Time Performance, Anytime

Always Connected – Smarter Baling Made Simple

With Kverneland Sync, your baler is continuously connected to IsoMatch FarmCentre, providing real-time access to critical machine parameters and performance indicators. This seamless connectivity keeps you and your team up to date on essential baler metrics, ensuring smooth, uninterrupted operations.

Remote Service – Minimize Downtime with Kverneland ServiceCentre

Kverneland ServiceCentre integration allows technicians to remotely diagnose and address any issues with your baler, minimizing downtime and ensuring you're always ready for the next job.

Additionally, Kverneland Sync enables geofencing to help protect your baler against theft, and an accumulator lets you locate your machine even when it’s not connected to a tractor.

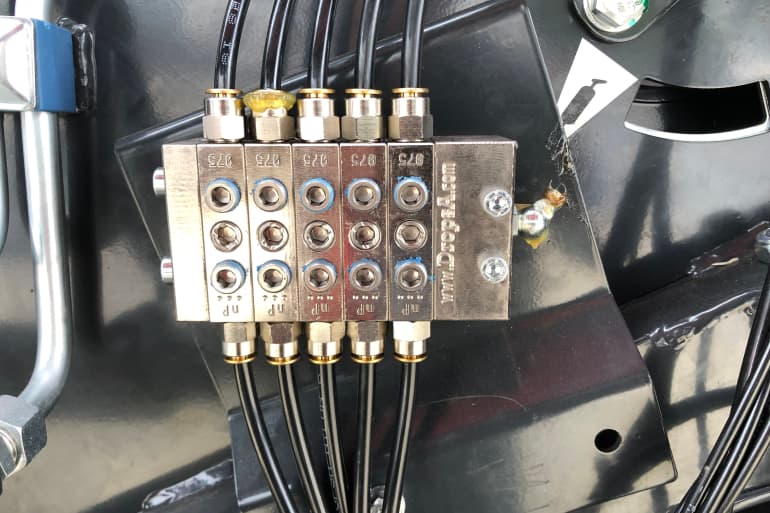

- Bearings are simply greased from four centralised grease banks. Sequential distribution ensures an equal quantity of grease is supplied to each bearing.

- Keeping chains correctly lubricated is crucial for an extended lifetime. 6500F is equipped with an automatic system supplying oil to each individual chain.

Precision Farming

Precision Farming

When deciding what equipment to purchase, it is not always easy to find the optimal solution in the broad market offering of today. Technology is developing fast and tractors and implements are more and more equipped with high tech electronics. We understand this complexity and are committed to provide you with easy farming solutions. Therefore these cost-efficient ISOBUS Universal Terminals, IsoMatch Tellus PRO and IsoMatch Tellus GO+ are made for easy machine control and efficient farming.

With its advanced hardware and software features, the IsoMatch Tellus PRO provides the optimal precision farming solution for an all-in-one control system inside your tractor cab.

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything a farmer needs to get the maximum out of his machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives the farmer the opportunity to view and control two machines and processes simultaneously.

Work easy. Be in control.

IsoMatch Tellus GO+ is especially developed for controlling the machine in a simple way. The farmer is in full control of the machine in exactly the way he wants. Easy set up the machine with the soft keys via the 7-inch touch screen. And, optimal control while driving, just use the hard keys and rotary switch. Controlling the implement has never been so easy.

This can be you your first step into Precision Farming

IsoMatch Tellus GO+ makes it easy to control any ISOBUS machine from your tractor cab. IsoMatch GEOCONTROL enables you to achieve higher yields, lower costs and do your work with less hassle. This licence key is divided in two parts, Section Control and Variable Rate Control, which are available from the IsoMatch Shop. Now you can buy the specific functionality that you need.

The IsoMatch Eye is the camera option in the IsoMatch product range.

IsoMatch Eye is a camera that has been developed for use with our sophisticated IsoMatch Tellus GO+ and IsoMatch Tellus PRO dual screen terminal. The IsoMatch Eye is switchable from rear view to standard view.

It gives you full control and overview of entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety e.g. when reversing the machine or manoeuvring around obstructions.

SMART

Changeable from rear view to standard view

EFFICIENT

Full control and overview of entire machine operation

EASY

Night vision by integrated LED’s

Technical specifications

Technical specifications

Download brochure| 6500F PF | 6500F CF15 | ||

|---|---|---|---|

| Bale chamber: | Full Roller | Full Roller | |

| Bale size (m): | 1.23 x 1.25 | 1.23 x 1.25 | |

| Intake: | PowerFeed rotor | ChopFeed 15 | |

| Binding: | Net | Net |

All variable chamber balers and the heavy duty fixed chamber baler are Tractor Implement Management (TIM) compatible.

Technical specifications

Technical specifications

Download brochureModel |

Bale Diameter |

Intake System |

Binding |

6500F CF15 |

1.23 x 1.22m |

ChopFeed-15 |

Net |

6500F PF |

1.23 x 1.22m |

PowerFeed |

Net |

All variable chamber balers and the heavy duty fixed chamber baler are Tractor Implement Management (TIM) compatible.