Kverneland Helios 2000

Weeder | Rotary hoe

Efficient weed control is a prerequisite for healthy plant growth as the basis for yield, profit and safe food production.

Rotary hoe for mechanical weed control in cereals and row crops

The advantages of this Rotary hoe

Strong in weed control with low impact on crops Perfect ground following and penetration High working quality and even depth control Stimulating physico-chemical reactions and soil life Protecting soil moistureDescription

The Kverneland rotary hoe, Helios, carries out selective mechanical weeding efficiently under any soil conditions, at lower and higher speeds (6 to 15km/h) with low impact on the growing crop.

The tandem star wheels made of cast-iron allow highly effective harrowing at a constant depth, even in hard and dry soil and mulch conditions. Each tandem row is individually mounted. The slender shape of the arm is fixed by conical pin, wear-resistant and ensuring smooth and stable operation. The special back of spoon design penetrates the soil, lifts the weeds whilst being gentle to the crop.

The following harrow equipped with curved tines will keep the weeds on the surface to dry out. The movement of soil onto the cultivated plants is avoided. By adjusting the speed, Helios works only as aggressively as needed.

Highlights

- Weeds taken onto the surface to dry out

- Adjustable and even working depth

- Adjustable to the level of emerging crops and sowing depth

- No blockages also in mulch conditions

- Precise speed management to work only as aggressively as needed

- Large capacity and high speed

- Cracking the upper topsoil, breaking the slaking crust

Features

Crop and soil benefit from 3 actions in one pass

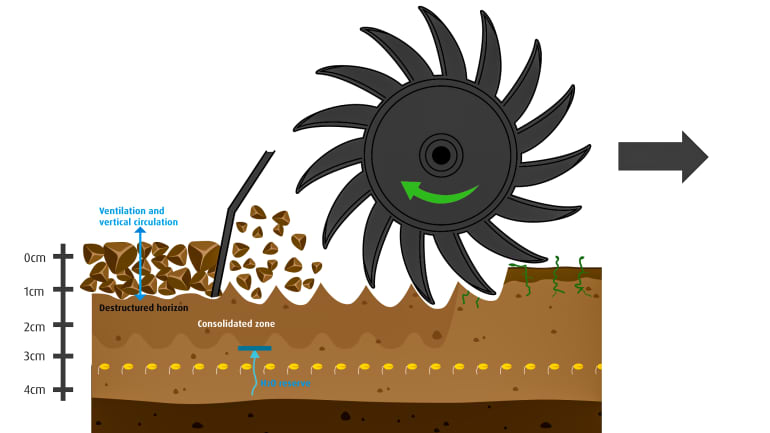

The unique design of the rotary-driven star-wheels and its application combines several beneficial impacts on the soil and crop: crust removal without projection, up-the-seed layer packing and upper layer structuring, weeds elimination by the combination star-wheels and following harrow.

1. Selective weed control

The back of spoon design, curved upwards, work without digging, by gravity. It’s operation does not require a high driving speed. Under any soil condition, even the most demanding ones (surface capping, clay, pebbly or residue-cluttered soils), it can be operated at 6 to 15 km/h, with low impact on the growing crop. Thanks to its 2.2 tons-weight (6m), the HELIOS rotary hoe rests well in the soil and fully respects the depth control above the seedbed. Thereby, it allows crossing the passes. The “wheels and comb harrow” combination enhances the weeding effectiveness about 40%.

2. Stimulating physicochemical reactions and soil life

By tackling the soil surface with the ”back of spoon” the wheels generate a cracking impact over 3cm either side, being a 6cmwide stripe tilled 3cm deep. This operation will prepare for the pass of the comb harrow’s teeth and help an accurate control of it’s work, preserving the seedbed. By disrupting the topsoil’s upper layer, the harrow restores the fluids, water, air, vertical flows and stimulates physico-chemical reactions and soil life.

3. Protecting soil moisture

By cutting the rising damp from the surface, the HELIOS rotary hoe reduces evaporation water losses. By blocking it under the packed layer, it saves water reserve in the seedbed layer. This bonus will also be profitable for the crop’s start and growth.

High quality with long lasting components

Double H-frame

The double H frame increases the penetration force by transferring the load to the ground-driven star wheels. Its sturdy concept provides safe transport on roads. The HELIOS is equipped with a standard Cat. II linkage.

Tandem star wheel bogie

Each star wheel with arm segment is protected by a spring or by hydraulics as an auto-reset system. The special shaped arm and the tandem bogie which is especially wear-resistant allows the lifting of the arm in case of obstacles. Due to the exclusively slim profile and curved shape, they carry out weed control with consolidation of the subsoil and aeration of the surface horizon. They pass cleanly in all conditions and even in mulch and stones. The angle of the stars always stay in the same position.

For each row, two star wheels are mounted individually as a bogie to perfectly follow the ground contour. The arm is fixed by the conical polymer ringed axle, no play or deformation of the axle possible, only a periodic tightening. It is wear-resistant and ensuring smooth and stable operation. The bearing has been designed for intensive use. Guides ensure perfect alignment of the stars in the driving direction, even with lateral stresses. At the same time, the short distance of the star wheels allow a combined work of both wheels and a stronger action onto the ground.

The Kverneland Helios offers extended options and benefits for cereals and row crops

The rotary driven star-wheel design of the rotary hoe, HELIOS, adapts to individual farming concepts and will be a good partner for a wide range of applications in spring and autumn. For successful weeding, the correct timing is of utmost importance and needs to be adapted to the soil conditions, the weed pressure and the machinery of the farm.

For all field conditions

... whatever the soil’s textures if stony or mulch condition

... in draught or after rain falls

... as aggressive as needed at lower but also higher speeds (6 to 15km/h)

... 3 to 6.4m working width with constant working depth

Weeding in wide range of crop establishment

... before emergence on bare ground as blind weeding,

... to 4 leaves-stage maize, cereals, beans etc.

... to 6-leaves stage sunflowers, Faba beans

Stimulating physico-chemical reactions and soil life

... supporting soil aeration and mineralisation

... protecting soil moisture

... loosening and crumbling again after rain falls and sun

... consolidation of the subsoil

... destroying of eggs and larvae e.g. of slugs as pest control

The cast-iron steel, ground-driven star wheels excel by the special back-of spoon design. Curved upwards, they work without digging by gravity. They lift the weeds particularly well whilst being gentle to the crop with no splashes or projections.

The special back of spoon design allows efficient penetration even in difficult soils without any blockages. For extremely crusted soil, there is the option of reversing the stars in the opposite direction.

In addition to the weed control, by tackling and disrupting the soil surface, the star wheels crack the upper topsoil. The stars and bearings are maintenance-free. The special shape of the stars makes them self-sharpening for intensive use.

The HELIOS can be equipped either with spring or hydraulic “Soft control” overload protection to ensure a constant working depth over the entire width.

With the hydraulic “soft control” system, the star wheel elements are provided with the same oil pressure for an even depth control over the entire working width independent of the surface. The Hydraulic linkage is positioned between the cylinders of each star wheel. Each element maintains the same ground pressure. Additional pressure can be applied on the star wheels.

With the mechanical version each arm is independent equipped with an infinitely adjustable mechanical spring system. The ground pressure setting (penetration force) is adjustable by tightening a nut on each element.

In addition to the two standard gauge wheels positioned in front of the middle frame bar, two optional gauge wheels can be fitted at the outer extensions. This will optimize the following of ground contour and ensure stability and a constant depth control, especially with larger working widths.

Depth setting is done mechanically via a scale for precise depth adjustment.

Parking legs

Original parking legs are delivered as standard for storage of the machine. The parking legs allow an easy and safe coupling and uncoupling to the tractor.

In order to ensure perfect levelling and to create an even weatherproof surface, Kverneland offers a single row following finger harrow in the final working zone. The rear-harrow operates over the entire working width of the HELIOS. The following harrow finishes the job and preserves the seedbed. It restores the fluids, water, air and stimulates physico-chemical reactions and soil life.

The following harrow supports the weed control as it uncovers and pulls out the uprooted weeds of the soil, leaving them on the surface to dry out in the sun. As the weeds are lighter than the soil particles thrown up, they fall more slowly and lie on top surface after passing over. They dry out quickly - regrowth is practically impossible. This is particularly important with rhizome and other weeds that could start growing again.

Moreover, the following harrow completes the cracking of the surface by the star wheels. By disrupting the topsoil’s upper layer the harrow restores the vertical flows, stimulates physico-chemical reactions and soil life.

The fingers bent at the end allow a progressive soil flow without the need of higher power requirement. The fingers are overload protected to avoid damage in stony or other difficult conditions. Individual springs ensure the releasing of the tines and keep levelling quality even in stony conditions.

The intensity of the harrow can be adjusted via two parameter for a perfect result:

- The angle of aggressiveness in three positions: smooth, medium and strong.

- The weight on the harrow, by a compressing spring for variable additional weight or a floating position.

Technical specifications

Technical specifications

Download brochure| Model | Helios 2030 | |

|---|---|---|

| Frame | mounted rigid | |

| Working width (m) | 3.06 | |

| Transport width (m) | 3.08 | |

| Linkage | CAT. II | |

| Gauge wheels | Standard: 2 / Option: 2 additional | |

| Gauge wheel - Size | 18.5x8.50-8 | |

| No. of star wheels | 34 | |

| Ø star wheel (mm) | 530 | |

| Star wheel width (mm) | 22 | |

| Star wheel weight (kg) | 10.9 | |

| No. of tines per star | 16 | |

| Star spacing (cm) | 9 | |

| Star wheel pressure adjustment | Mechnical or hydraulic. “Soft-Control” | |

| Following Harrow | Option | |

| Following Harrow tine length (mm) | 410 x 7 | |

| Following Harrow - Pressure adjustment | By compressing spring | |

| Following Harrow - Aggressiveness adjustment | By multi-position system | |

| Max. weight with following harrow (kg) | 1150 | |

| Min. Power requirement (hp) | 80 | |

| Max. Power requirement (hp) | 200 |

Technical specifications

Technical specifications

Download brochureModel |

Helios 2030 |

Helios 2048 F |

Helios 2060 F |

Helios 2064 F |

Frame |

mounted rigid |

mounted fold (3 frame sections) |

mounted fold (3 frame sections) |

mounted fold (3 frame sections) |

Working width (m) |

3.06 |

4.80 |

6.12 |

6.40 |

Transport width (m) |

3.08 |

|||

Linkage |

Cat. II |

|||

Gauge wheels 18.5 x 8.50-8 |

Standard: 2 / Option: 2 additional |

|||

No. of star wheels* |

34 |

52 |

68 |

72 |

Optional following harrow tine length (mm) |

410 x 7 |

410 x 7 |

410 x 7 |

410 x 7 |

Max. weight with following harrow (kg) |

1,150 |

1,800 |

2,200 |

2,300 |

Min./max. power requirement (hp) |

80/200 |

100/220 |

120/240 |

130/250 |

*Star wheels: Ø530mm, 22mm wide, 10.9kg, 16 tines per star, spacing 9cm, pressure adjustment mechanically of by hydraulics "soft-control"