Kverneland 860

Bale Chopper | Bale chopper / feeder

Finish the job faster

Trailed bale chopper/feeder with 3.0m3-6.0m3 loading capacity

The advantages of this Bale chopper / feeder

- 3.0m3 chamber

- Blowing distance up to 20m

- Wide flywheel housing for increased capacity

- Hydraulic comb to control flow towards flywheel (863 Pro only)

- Belt clutch anti-blockage solution (863 Pro & 866 Pro only)

- Two speed gearbox for reduced flywheel speed

Description

A key aim of the Kverneland 860 Pro series is to provide more capacity by shredding the material faster. Flywheel housing and blowing paddles have increased in dimensions to increase performance. This means more material is fed faster into the flywheel, finishing the bale at an impressive pace. Kverneland 863 Pro and 866 Pro comes with a new designed belt clutch solution to disengage the shredder rotor. The shredder rotor can be hydraulically disengaged from the tractor cab. The comb is used to control the flow of material into the flywheel, especially when feeding loose material. The top guards reduces spillage and guides material towards the shredder.

Highlights

- 3.0-6.0m³ chamber

- Blowing distance up to 20m

- Hydraulic comb and top guard (863 Pro only)

- Belt clutch solution to disengage shredder rotor (863 Pro & 866 Pro only)

- Optimised drum, flywheel and chamber design for maximum capacity and throughput

- Unique drum-knife configuration to handle a wide variety of materials

- Two speed gearbox for reduced flywheel speed when discharging feed materials

Features

Features

- The swivelling chute operates in 4 stages to optimize the blowing distance for bedding

- Blowing distance up to 20m.

- Designed with a turning radius of 260° which enables easy access to even difficult reachable spaces.

- The 3-stage movement enhance the feeding perfomance without blockage even on long fibrous material.

- To provide the correct flywheel speed for bedding and feeding Kverneland 863 and 864 is fitted with a two speed gearbox.

- At lower speeds the flywheel ensures a metered flow of silage or hay for feeding.

- At high speed a powerful blow for the most efficient distribution during bedding is ensured.

- The gearbox speed is adjusted via the handle on the front of the machine.

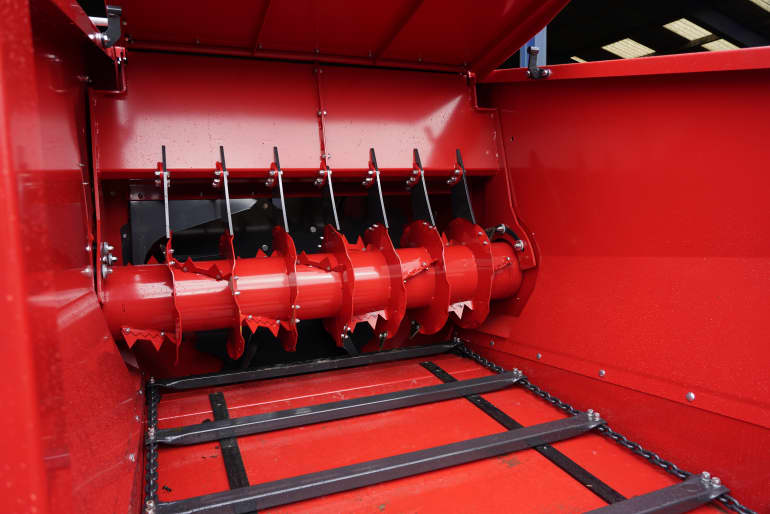

- The Kverneland 863 - 864 features a unique drum – knife configuration.

- Knives are mounted on angled rings so that they pass a fixed ‘comb’ on alternative sides.

- This ensures that materials are cut and fed into the flywheel chamber evenly, reducing the risk of blockage, offering even discharge & leaving the drum and comb clean.

- The drum is fitted with 14 blades as standard, but will accept a further 28 blades according to material type – simply bolt them on in a matter of minutes.

- A patented system - the knives pass the fixed comb on alternative sides for a more even cut.

- The hydraulically operated rear door fitted provides a self loading facility for easy loading of square and round bales.

- Tailgate and floor chain can be operated via the remote control on the side of the machine.

- The rear door also offers the ability to carry a second round bale for increased capacity.

- A bale kit can be fitted to the end of the tailgate to ensure that the bales stay in position during operation.

- The size of the bale chamber makes it very easy to load the material with a loader - and two round bales can be loaded at the same time - saving time.

Besides the features shared with the standard 863, 863 Pro also includes hydraulic activation of shredder rotor, hydraulic comb and top guard, all adding to easier control and more productivity.

- With the hydraulic belt clutch solution the shredder rotor can be run independently from the flywheel and can be disengaged when starting up the flywheel. This allows the flywheel to go to full speed before the shredder rotor is activated and starts feeding material into the flywheel housing.

- The operator will enjoy the new hydraulic comb that is controlled from the tractor cab. It is an efficient tool to control the flow of material into the flywheel, to avoid blocking flywheel and chute. Especially when feeding loosing material like clamp silage it proves to be a valuable feature.

- The top guard reduces spillage and ensures material stays inside the bale chamber. It efficiently guides material towards the shredders.

Technical specifications

Technical specifications

Download brochure| Model | 863 | 863 Pro | 866 Pro | |

|---|---|---|---|---|

| Chute | 4-stage Sw. Chute | 4-stage Sw. Chute | 4-stage Sw. Chute | |

| Cubic volume (m3) | 3.00 | 3.00 | 6.00 | |

| Blowing distance* (m) | up to 20 | up to 20 | up to 20 | |

| Chassis | Trailed | Trailed | Trailed | |

| Metering system | Single Drum | Single Drum | Two-Drum Design | |

| PTO power req. min (kW/hp) | 51/70 | 51/70 | 55/75 |

* Depending on material and barn-specific conditions |

Technical specifications

Technical specifications

Download brochureModel |

Cubic Volume |

Load Capacity |

Hydr. Belt Clutch & Comb |

Power Req, Min. |

863 |

3.00m3 |

1500kg |

No |

51/70kW/hp |

863 Pro |

3.00m3 |

1500kg |

Yes |

51/70kW/hp |

* Depending on material and barn-specific conditions |