Kverneland 6250 Plus

Kverneland 6250 Plus

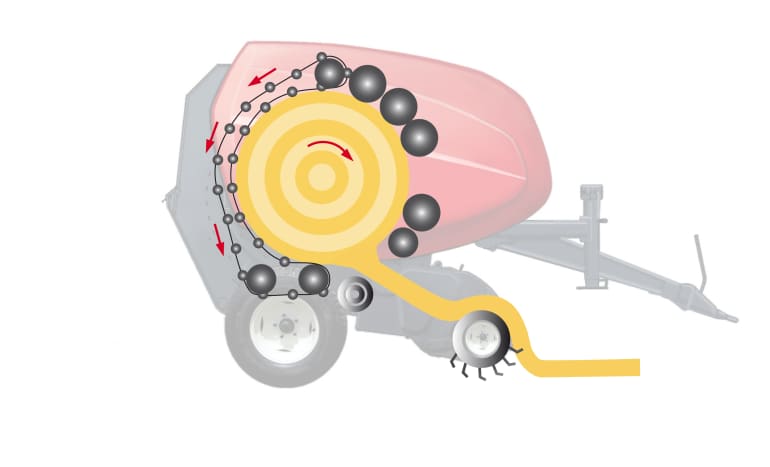

The combined bale chamber concept, with a roller at the front and chain and slat at the rear, is ideal for dense and well-shaped bales in all conditions.

Highlights

Low profile pick-up for fast & efficient throughput Easy and fast unblocking of crop blockage Patented PowerBind net system RotaMax bale chamber Intuitive control with the Focus 3 & ISOBUS terminalDescription

The Kverneland 6250 Plus series fixed chamber balers are designed for maximum flexibility in all crop conditions. Perfectly shaped bales, combined with long-lasting, reliable performance, ensure that the Kverneland 6250 Plus series will be a profitable investment. The Kverneland 6250 Plus has a bale chamber designed with five rollers in the front section of the bale chamber and chain and slats in the tailgate. This combined solution gives excellent crop handling in all conditions with consistent, high-density bales in both wet and dry material.

Highlights

2.0 or 2.20m working width low profile pick-up with small diameter reel for fast and efficient throughput

Feeder Fork, PowerFeed rotor intake or Supercut 14 knife pre-chopping device

Parallelogram Drop Floor system for easy and fast unblocking of crop blockage

Patented PowerBind system for fast and reliable net & twine binding

RotaMax bale chamber- roller front section with chain & slat tailgate for high bale density and good bale shape in all conditions

Simple and intuitive control with the Focus 3 terminal and optional Isobus configurations

Features

- The Kverneland 6250 offers a bale chamber designed with 6 rollers at the front and chain and slat at the rear part.

- The combined solution gives excellent crop handling in all conditions with consistent, high density bales in both wet and dry material.

- The chains and slat of the rear section give an early and 100% regular bale rotation and hence faster bale formation leading to denser core of the bale. Even in very dry crops.

- The heavy duty rollers of the front section ensure a well-shaped bale finish and very tight bales.

- The chains in the rear section results in less crop loss compared to a full-roller concept.

- The tail gate has a completely enclosed design to reduce crop loss to a minimum, especially when operating in silage.

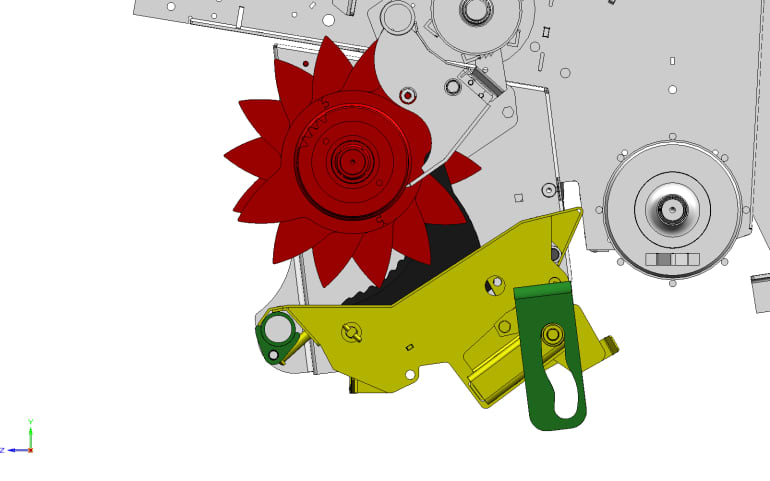

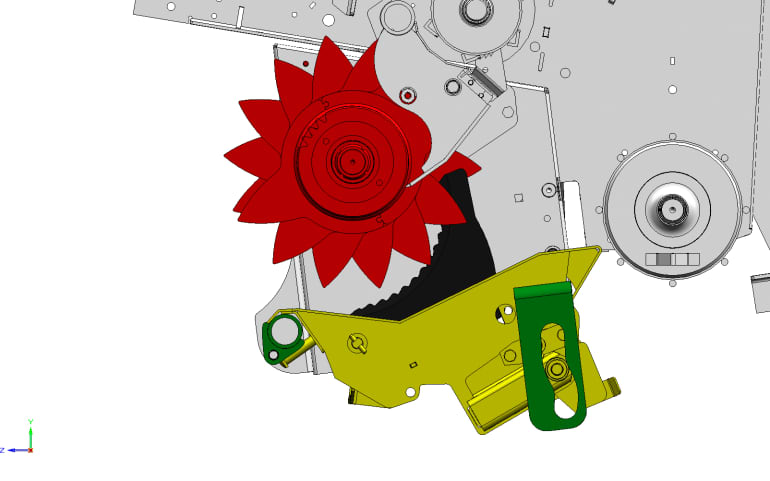

Parallelogram Drop Floor system for easy unblocking

- Parallelogram Drop Floor enables the operator to clear blockages easily from the tractor cab without any crop loss.

- Drop the floor to free the rotor of blockage, engage the PTO to feed the blockage through and close the floor to continue baling

SuperCut-14

- The SuperCut-14 knife chopping system provides a fast and efficient flow into the baler. With a chopping length of 70 mm it is the ideal solution for producing tight bales with superb silage quality.

- Each individual knife is spring protected against foreign obstacles. The knife will immediately return to the working position once the obstacle has passed.

SuperCut-25

- The SuperCut-25 pre-chopping system offers the ultimate solution for short chop baling with a chop length of 40mm. The short and precise chop provides dense and airtight bales for the best possible silage quality.

- The operator can choose to engage 25, 13, 12,6 or 0 knives, giving maximum flexibility in operation.

- The SuperCut- 25 knives are fitted with dual action protection against foreign objects. Each knife is individually spring protected and can move in two directions

SuperFeed Rotor Intake for Ultimate Capacity

Truly impressive intake capacity can be achieved with the SuperFeed rotor intake system - handling all crop types with ease, whatever the conditions.

Single or Dual Fork Feeder

- The fork feeder versions are fitted with a cost-efficient fork feeder intake system. This system provides a direct feed into the bale chamber, and the wide opening allows almost unrestricted intake capacity for a fast and efficient bale start.

- In addition, the fork feeder gives less vibration and reduces power consumption.

- The fork feeder is provided with a crop press above the pick-up that ensures a regular crop flow even from large bulky swaths.

- Dual fork feeder with double feed tines ensures even higher capacity, while still safeguarding fragile crop types.

TIM (Tractor Implement Management)

TIM is a cross-product and cross-manufacturer ISOBUS solution for the agricultural machinery industry whereby the implement is able to control certain tractor functions. It enables two-way communication between tractors and implements, allowing both machines to work in perfect harmony. As well as increasing efficiency, the possibility of human error due to fatigue is also greatly reduced.

TIM technology has the advantage of significantly increasing driver comfort by automatically performing many of the repetitive actions of the baling process. The cost aspect is another factor to bear in mind. Highly efficient use of TIM-equipped baler results in lower costs for parts that wear out.

- TIM system as optional equipment

- TIM takes most of the work off the operator's hands when baling

- Significant increase in comfort for the operator, as endless work steps are saved

- Reduced operator fatigue and faster completion of work while maintaining high bale quality

- High user-friendliness of the TIM system, which even regularly changing operators can quickly master

Focus 3 Control

Kverneland Group Mechatronics has recently launched a new operator terminal, the Focus 3. This terminal is developed for specific implement types and will only be delivered as package for those implements, together with the electronics for balers. The terminal Focus 3 is positioned in the market as an economy solution.

- Focus 3 terminal is easy to learn and very intuitive, with control terminal with focus on functionality and operating simplicity.

- Focus 3 terminal is a universal control terminal which can also be used with other implements from the Kverneland Group.

- Focus 3 terminal gives you full control of all functions from the tractor cab. They are shown on a large, clear digital display.

- Focus 3 terminal monitors and controls all necessary functions with all relevant parameters are visible at a glance. The control box is also driving the binding automatically without any intervention from the operator.

Easy Loading

- The very low loading height and the very easy threading of the system mean minimum downtime and maximum time baling. Storage for three rolls of net means you don’t have to worry about running out of net when the pressure is really on during long working days.

Twine Tying

- Automatic twine tying with the fast acting double tube system means simultaneous binding of both edges of the bale, keeping binding time to a minimum. Over crossing of twines in the centre of the bale provides no loose ends at the end of the binding cycle.

- The system is fully user programmable to make sure you make the best looking bales in all crop conditions.

PowerBind Net Wrap

- The Fix chamber baler is equipped with the patented new PowerBind net wrap system. PowerBind provides positive and reliable injection of net in all crop conditions, while also eliminating potentially troublesome feed rollers. Additionally the PowerBind provides one of the fastest net wrap actions available. This means minimum downtime and maximum time baling

- Net is fed right to the outside of the bale, with a specially widened entry channel, which also allows extra wide net types to be utilized if required.

- The simple net wrap system allows the net to extend past the edge of the bale. The 1.30m net is wider than the baling chamber, so that the net can be pulled over the edge of the 1.20m bale. The result is consistent perfectly shaped and tightly secured bales

Precision Farming

When deciding what equipment to purchase, it is not always easy to find the optimal solution in the broad market offering of today. Technology is developing fast and tractors and implements are more and more equipped with high tech electronics. We understand this complexity and are committed to provide you with easy farming solutions. Therefore these cost-efficient ISOBUS Universal Terminals, IsoMatch Tellus PRO and IsoMatch Tellus GO+ are made for easy machine control and efficient farming.

With its advanced hardware and software features, the IsoMatch Tellus PRO provides the optimal precision farming solution for an all-in-one control system inside your tractor cab.

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything a farmer needs to get the maximum out of his machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives the farmer the opportunity to view and control two machines and processes simultaneously.

Work easy. Be in control.

IsoMatch Tellus GO+ is especially developed for controlling the machine in a simple way. The farmer is in full control of the machine in exactly the way he wants. Easy set up the machine with the soft keys via the 7-inch touch screen. And, optimal control while driving, just use the hard keys and rotary switch. Controlling the implement has never been so easy.

This can be you your first step into Precision Farming

IsoMatch Tellus GO+ makes it easy to control any ISOBUS machine from your tractor cab. IsoMatch GEOCONTROL enables you to achieve higher yields, lower costs and do your work with less hassle. This licence key is divided in two parts, Section Control and Variable Rate Control, which are available from the IsoMatch Shop. Now you can buy the specific functionality that you need.

The IsoMatch Eye is the camera option in the IsoMatch product range.

IsoMatch Eye is a camera that has been developed for use with our sophisticated IsoMatch Tellus GO+ and IsoMatch Tellus PRO dual screen terminal. The IsoMatch Eye is switchable from rear view to standard view.

It gives you full control and overview of entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety e.g. when reversing the machine or manoeuvring around obstructions.

SMART

Changeable from rear view to standard view

EFFICIENT

Full control and overview of entire machine operation

EASY

Night vision by integrated LED’s

Technical specifications

Technical specifications

Download brochure| 6250 Plus F | 6250 Plus R | 6250 Plus SC14 | ||

|---|---|---|---|---|

| Bale chamber: | Rollers & chain | Rollers & chain | Rollers & chain | |

| Bale size (m): | 1.20 x 1.25 | 1.20 x 1.25 | 1.20 x 1.25 | |

| Intake: | Feeder Fork | PowerFeed rotor | SuperCut-14 | |

| Binding: | Net, Net & Twine | Net, Net & Twine | Net, Net & Twine |

Technical specifications

Technical specifications

Download brochureBale Diameter |

Intake System |

Binding |

|

6250 Plus F |

1.20 x 1.25m |

Feeder Fork |

Net, Net & Twine |

6250 Plus R |

1.20 x 1.25m |

PowerFeed |

Net, Net & Twine |

6250 Plus SuperCut 14 |

1.20 x 1.25m |

SuperCut 14 |

Net, Net & Twine |