Kverneland iXdrive S6

Sprayer | Self-propelled sprayer

Quality, productivity and performance!

The Kverneland iXdrive S6 series consists of the iXdrive HP (High Performance) as a basic model and the iXdrive HP ECODRIVE as the top model, including features like a Power Tech engine Stage V, iXflow-E individual nozzle control and iXclean Pro valve management. Kverneland offers a spray range which fits to both arable farmers and contractors.

The advantages of this Self-propelled sprayer

- EasySet control panel a convenient workspace

- iXspray for a user friendly operation

- Excellent driving comfort

- iXclean Pro fully automatic valve management system

- iXflow-E high pressure recirculation system

Description

The iXdrive S6 is available up to a 6150l nominal tank capacity in combination with two different boom types: the HSA aluminium spray boom (24-30m) and the HSS steel boom (24-40m). The Boom Guide system ensures a perfect spraying pattern for high precision spraying. Unique hydro pneumatic suspension on both axles provides operator comfort and boom stability in transport and field operation. The EasySet control panel offers a clean and convenient workspace with all required components directly at hand. The spraying technology is easy to operate from the cab with the Tellus 1200 terminal, Grip joystick and the innovative iXspray software with intuitive touch interface. Control your fleet, manage tasks remotely or analyse machine performance data with FarmCentre.

Highlights

- The EasySet control panel offers a clean and convenient workspace with all needed components directly at hand.

- iXspray means an intuitive user interface and user friendly operation which ensures that spraying is done in the most easiest and efficient way.

- Excellent driving comfort.

- iXclean Pro fully automatic valve management system from the premium cab.

- iXflow-E - high pressure recirculation system with individual electric nozzle control to increase crop quality and save costs.

- The parallelogram combines stability with balancing and limited vertical movements to minimise spray height deviations.

- FarmCentre is applicable for Kverneland ISOBUS machines – linking implements and terminals in one continuous flow of data and connectivity.

Features

Features

The DAT camera technology on the Kverneland sprayer range is a precision tool which supports farmers and contractors in patch spraying and with that a reduction of spray liquid.

The DAT Ecopatch recognises and categorises weeds in fields with wheat, cereals and oil seed rape. When weeds are recognised by the camera, a signal is sent to the Kverneland field sprayer and the appropriate nozzles are activated, up until a speed of 10 km/hr.

The system is built on pragmatism, relying on the agronomic principle of weeds growing in patches, which means a cost-effective solution.

Using the DAT Ecopatch on a Kverneland sprayer is easy. Just activate the system by clicking a button on the IsoMatch Tellus PRO or GO+ or any other AEF certified terminal and the combination is ready to go. Automatically, the weed will be recognised and the nozzles are turned on and off.

The data, such as as-applied data and weed heat maps will be directly available and can be used directly in combination with for example IsoMatch FarmCentre for further analysis.

With the DAT camera technology on a Kverneland sprayer savings on spray liquid up to 58%* can be reached. Additionally, the non-sprayed areas will preserve healthy crop from unnecessary treatment, which means less crop damage and another benefit is the increased capacity, as more hectares or fields can be covered with one tank of spray liquid.

Inquire today what the DAT system can do for you.

*2024 DAT trials in canola

HSS 24-27-28-30-32-33-34-36-38-39-40m Compact Side Folding Steel Booms

- The special HSS profile combines a minimum of weight with maximum strength and stability. The HSS boom range is designed for professional use. It's triangular construction provides perfect integration of the stainless steel spray lines, nozzles and nozzle holders and the optimal hose routing where all is well protected. The HSS boom range consists out of a range of two-part folding (24-30m) and three-part folding (32-40m) spray booms. HSS 32-40m 2nd generation boom is designed for higher capacity, higher working speed and higher demands.

HSA 24-27-28-30m High Tech Side Folding Aluminium Booms

- The high tech HSA aluminium spray boom efficiently protects the nozzle holders within the bottom profile of the boom. This profile is designed for easy cleaning with no sharp angles or corners for residue and liquid to collect. The anodised surface protects against corrosion and scratches.

iXflow-E

- The HSS and HSA spray booms are equipped as standard with iXflow-E. iXflow-E is the high pressure recirculation system with electric nozzle control. There is a free circulation of chemicals with a return of spray liquid back to the tank when spraying stops. This means there is no sedimentation in the spray lines and no dead ends for spraying or cleaning. During spraying each section gets under pressure from both ends of the spray lines, so the operator can immediately start spraying without any pressure drop. It is easy for the operator to program the number and size of sections which fits the best to their requirements and field situations.

Boom Guide Pro

- This advanced system uses three ultrasonic sensors to control left- an right-hand boom sections independently for the ultimate guidance in the most challenging field conditions. It can deliver positive and negative lateral movement on each side of the boom to follow the contours in every situation!

Boom Guide ProActive

- The system proactively reacts on boom movement and controls both the central and independent slope correction, as well as boom lift functions to guide the boom over the crop canopy, soil surface or a combination of both modes.

Boom Guide 5 Sensor Extension

- The Boom Guide 5 sensor extension provides two additional ultrasonic sensors to ensure proper height measurements with booms reduced to 24 metres working width by folding the tip-ends.

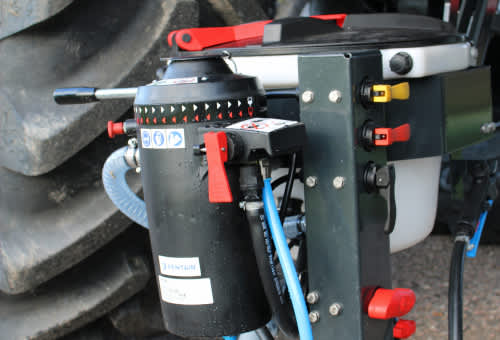

EasySet control panel.

- The EasySet control panel is located between the wheels, at the left hand side of the iXdrive. The panel is redesigned to create a clean and convenient workspace with easy access to all the connections and filters. The control panel is well protected with a bottom cover to keep your operational area free of dirt and chemicals. It is equiped with a Focus3 colour terminal for valve operation and an operating panel for engine and hydraulic functions. The chemical inductor has a new compact design and is hydraulically folding. Furthermore, can be equipped with a Closed Transfer System, which will be obligatory in Europe in short term.

iXclean Pro

- The iXdrive is equipped as standard with iXclean Pro our fully automatic electric valve management system. It means all functions can be controlled from the cab or the control panel. Switching between filling, agitation, spraying, diluting, priming, rinsing and tank cleaning is extremely easy: just push the button! iXclean Pro also offers a fully automatic multi-step rinsing and cleaning program again with the push of one button! It just takes a few minutes and residue levels are after automated cleaning below 1%.

Pump with unique service position

- The 520l/min piston-membrane pump of the iXdrive is positioned on the right side directly under the main tank resulting in the smallest hose lengths possible. Unique is the service position of the spray pump. The pump is mounted on a rail to be able to easily slid out or to take out completely for maintance purposes.

iXspray

- The innovative iXspray spray computer program is operated by the IsoMatch Tellus Pro ISOBUS terminal in combination with IsoMatch Grip joystick. iXspray guarantees an user friendly operation of the sprayer. iXspray is full of nice features to make the operators life easy, save time and avoid mistakes in a busy working season, for example pre-sets for spray jobs and boom configuration can be configured easily.

Wheel Axles

- The hydro pneumatic suspension on both axles provides operator comfort and boom stability both in transport and field operation. The 3D rear axle suspension allows axle movement, but limits the track influence on the spray boom. The strong chassis with an optimal gravity point brings a perfect 50%-50% weight balance in every situation, without any influence from tank filling or spray boom position. Manoeuvrability is guaranteed with 2-wheel, 4-wheel and crab steering modes as well as ErgoDrive headland control management as standard.

Adjustable Track Width

- For optimal protection of the crop the iXdrive S6 is available in three different ground clearances: 1.30m, 1.50m and 1.70m. The trackwidth for the 1.30m clearance frame is 1.80 - 2.25m. Both other clearances come with a track width of 2.25 - 2.95m both offering maximum stability and row spacing in different crops.

- Track width adjustment with hydraulic support is standard feature on the iXdrive. Optional is a hydraulic operation from the cab adding more comfort and flexibility.

The iXdrive S6 is equipped as standard with a HP (High Performance) drive line. The sophisticated hydraulic setup results in a more efficient use of the available power.

The standard HP model has a 250hp diesel engine and a hydraulic drive line set up for maximum and efficient use of the available power. The hydraulic system provides a step less speed variation reducing engine RPM when possible resulting in optimal efficiency and comfort. The engine is a John Deere 6 cylinder 250hp single turbo with European Stage V emission as standard. Optional available are a 250hp Tier 2 and 300hp Stage V engine.

Easy Operation

- The HP model is always operated by the manual joystick. This intuitive operation comforts the driver very quickly during field operation as well as during road transport. The brakes are activated by the brake pedal.

Continuous 4-wheel drive

- The iXdrive has a smart hydraulic layout which guarantees a permanent 4-wheel drive. The hydraulic drive line is fed by 2 hydraulic pumps: one for the front axle and one for the rear axle. The oil flow for one axle can not go to one wheel only, resulting in a permanent traction on all 4 wheels. This is always standard equipment and is always activated. Comfortable for the driver: he cannot forget to activate the 4-wheel drive and he will not get stuck accidentally.

Reliable wheel motors

- The HP wheel motors are optimised on all levels. Most important is the efficiency, where the motors can supply higher power especially at low speed, they still consume less power, which is even more reduced at higher speeds. This efficiency saves fuel and is in the meantime more efficient with the available power.

Integrated brakes

- The active brakes are integrated in the wheel motors. For the HP model only the front axle is equipped with active brakes.

The HP-ECODRIVE model is the top level offering automatic engine RPM which means maximal control.

The HP-ECODRIVE model is the top level drive line with standard 300hp stage V engine resulting in a super comfortable 1350 RPM engine at 40km/h road transport. With HP-ECODRIVE the engine RPM will automatically decrease when possible and increase when necessary. This obvious fuel savings result in maximum cost efficiency and comfort for the driver.

Easy Operation

- The HP-ECODRIVE model has a similar field operation as the HP model. During road transport the manual joystick only selects the driving direction. The driving pedal determines the speed and acceleration, whereas the brake pedal is operated when slowing down. The benefit is a very relaxed road transport operation, like a car with automatic gearbox or even better a continuously variable gear box.

Continuous 4-wheel drive

- The iXdrive has a smart hydraulic layout which guarantees a permanent 4-wheel drive. The hydraulic drive line is fed by 2 hydraulic pumps: one for the front axle and one for the rear axle. The oil flow for one axle can not go to one wheel only, resulting in a permanent traction on all 4 wheels. This is always standard equipment and is always activated. Comfortable for the driver: he cannot forget to activate the 4-wheel drive and he will not get stuck accidentally.

Reliable wheel motors

- The HP wheel motors are optimised on all levels. Most important is the efficiency, where the motors can supply higher power especially at low speed, they still consume less power, which is even more reduced at higher speeds. This efficiency saves fuel and is in the meantime more efficient with the available power. In combination with the HP-ECODRIVE technology the user experiences a step less speed variation providing power when it is needed and reducing engine RPM’s when possible.

Integrated brakes

- The active brakes are integrated in the wheel motors. The HP-ECODRIVE model has integrated brakes on all 4 wheels.

iXflex - hydraulic ground clearance adjustment

Minimise crop damage

Kverneland iXflex maximum flexibility in spraying. It is possible to spray with 1.40 metre ground clearance in low crops or on the road and switch to 1.85 metres clearance for spraying in high crops. Each wheel of the iXdrive S6 is individually suspended by an additional hydraulic cylinder within the dimensions of the lifting construction. This is on top of the well-known standard axle suspension on the sprayer.

Safe on the road

Because of the lower centre of gravity the operator can drive safely, even in difficult circumstances, hilly field conditions or during high speed in transport on the road.

iXflex hydraulic ground clearance is also possible in combination with automatic track width adjustment.

Only spray when it is needed

Increase the environmental protection by only spray when it is needed with the new SpotSpray application within the iXspray software on the IsoMatch Tellus terminal in combination with the Kverneland sprayer !

Optimal Crop Protection

The SpotSpray application is based on a predefined prescription map with zero application rates. These prescription maps can be made in a similar way as the Variable Rate Application (VRA) prescription maps, in combination the SpotSpray application the sprayer shuts on and off. This is done based on the predefined sections in the control terminal and can even be done with normal section valves on the sprayer. Only designated spots are sprayed, which is particularly helpful when targeting weed spots, thistles, wet areas, non-germinated areas and areas with soil problems.

Another benefit is that based on the area of the spots in the VRA map, it is easy to see exactly how much spray liquid is required in the sprayer. Capacity is also increased as more hectares or fields can be covered with one tank of spray liquid.

With a relatively small investment in the SpotSpray license on the IsoMatch Tellus terminal, the return on investment is high, due to saving time and money. With this, spot spraying becomes accessible for all famers and contractors.

With SpotSpray costs can be saved by reducing the spray liquid to be used and preserve healthy crop from unnecessary treatment. This also means less crop damage.

The complete Kverneland HSS steel spray boom range comes as standard with 50cm nozzle spacing. Additional nozzle holders can be added to the boom now to create 25cm nozzle distance. The 25cm nozzles distance is required by legislation and confirmed as a low drift technology in a limited number of countries.

Improved crop coverage and reduced drift reduction

The 25 cm nozzle distance will improve the crop coverage and drift reduction, as it is possible to spray closer to the target area at 30cm spray height, by keeping an accurate distribution of spray liquid at the correct level with the correct droplet size.

Increase spray window

Easy switching from 50 to 25cm nozzle distance means more flexibility during spraying and it creates more time to spray in optimal conditions. In addition, the weather has less of an effect. It is easy to change from 50 to 25 cm nozzle distance or the other way around. The 25cm nozzle distance is an optional add on, on top of the standard 50cm nozzle distance for all spray line systems (central sections, iXflow-Air and iXflow-E). Even it is possible as retrofit.

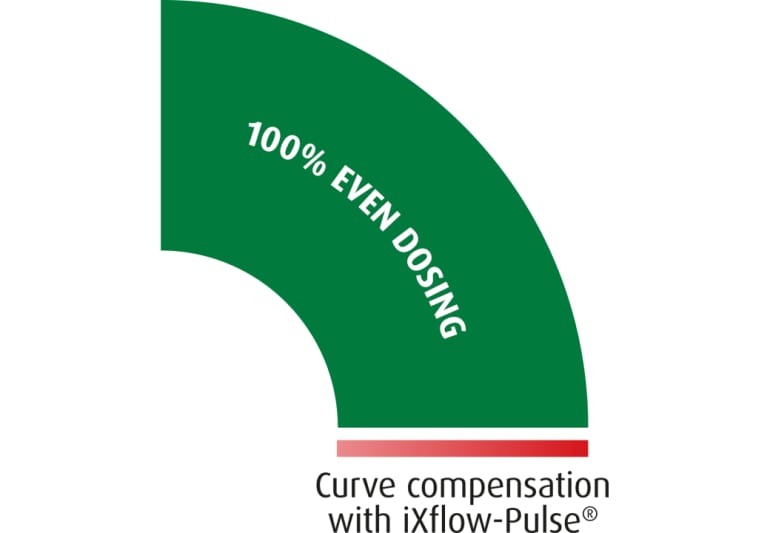

iXflow-Pulse - Pulse Width Modulation system - creates the most effective agronomical spraying due to an optimal balance between droplet size, crop coverage and water use, also under changing conditions of speed or application rate.

Optimal droplet size for maximum efficiency

iXflow-Pulse is creating a flexible and fast adjustable opening and closing time of the nozzles. When driving faster the opening time will become longer. When driving slower the opening time gets shorter, but by using the iXflow-Pulse the right droplet size will be kept.

Stable spraying pressure

Precision spraying is all about the right spraying pressure in combination with the nozzle to get the right droplet size. iXflow-Pulse (Pulse Width Modulation) takes care of a stable spraying pressure over a wide speed range during variation in application rate. For example, during speed variation at start/stop on headlands, slowing down during turning or when driving and spraying up or down the hill. Another benefit is that the pressure and flow can be adjusted separately as well as during operation. One nozzle can be used for a wider range of applications, which means less changes of nozzles required, saving time and increasing efficiency. There is also the ability to use lower pressure with the same nozzle in challenging or windy conditions. iXflow-Pulse improves the coverage of the spray target in combination with a minimalisation of drift and evaporation.

iXcurve - even dosing in curves

When spraying in different field conditions, for example driving in curves or passing obstacles, the left and right boom has a different speed and this can cause overdosing or under dosing. With the feature called iXcurve, which is included in the iXflow-Pulse system, the modulating spray pulses by adapting the opening and closing time to compensate the speed difference, resulting in an evenly covered crop or surface with the right amount of spray liquid.

Precision Farming

Precision Farming

When deciding what equipment to purchase, it is not always easy to find the optimal solution in the broad market offering of today. Technology is developing fast and tractors and implements are more and more equipped with high tech electronics. We understand this complexity and are committed to provide you with easy farming solutions. Therefore these cost-efficient ISOBUS Universal Terminals, IsoMatch Tellus PRO and IsoMatch Tellus GO+ are made for easy machine control and efficient farming.

With its advanced hardware and software features, the IsoMatch Tellus PRO provides the optimal precision farming solution for an all-in-one control system inside your tractor cab.

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything a farmer needs to get the maximum out of his machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives the farmer the opportunity to view and control two machines and processes simultaneously.

With manual guidance you are perfectly on track.

The IsoMatch InLine is a light bar which allows easy manual guidance. It is the perfect assistant to get you as close as possible to your desired A-B line. Mounted in the line of sight, you can easily see the distance from the A-B line and to which direction you should steer for the ideal position. The display of the IsoMatch InLine also displays the status of the machine sections, which adds more comfort of use. The LEDs can be dimmed for night operation.

SMART

Distance to A-B line with LED indication and a numeric display

EFFICIENT

Manual guidance in combination with IsoMatch GEOCONTROL

EASY

Displays status of machine sections

The essential accessory for IsoMatch GEOCONTROL.

The IsoMatch Global 3 is the GPS antenna, with DGPS accuracy, in the IsoMatch product range. It enables satellite navigation for site-specific section control, variable rate application, manual guidance and field registration.

SMART

Allows manual guidance, automatic section control and variable rate in combination with IsoMatch GEOCONTROL

EFFICIENT

DGPS accuracy without additional subscription fees

EASY

Easy to fit with mounting brackets included

Made for smart, efficient and easy farming

IsoMatch GEOCONTROL is an advanced software application within the IsoMatch Tellus PRO and IsoMatch Tellus GO+ that helps you to control all ISOBUS compatible Kverneland Group machines such as sprayers, spreaders and seeders! Combined with a GPS receiver it fulfils the future needs in terms of easy, smart and efficient farming!

The IsoMatch Grip is an ISOBUS auxiliary device developed for great operator comfort and efficient machine control. Its ergonomic shape and the complete freedom of assigning and controlling a total of 44 implement functions from one device are unique in the market today. From your fingertips you have endless possibilities to operate all machine functions as desired. And assignments are saved per machine making it even more applicable to your needs.

Whether you are a farmer or contractor with a fleet, IsoMatch FarmCentre gives you a complete overview of your business. You can track the movement of your fleet in real time or verify later where your machines have been operating. Keeping track of multiple machines spread over vast areas has never been so easy! Additionally, all alerts and notifications are sent directly to the IsoMatch FarmCentre web application, and the history of alerts is saved. Allowing dealer to access your account for remote support will decrease the risk of downtime and increase your productivity.

With IsoMatch FarmCentre, machine performance parameters can be tracked and analysed for optimal performance. Actual information about quantity of pressed bales, fertiliser consumption and more is shown in the application. All this you can check remotely from a computer or even a tablet or smartphone.

Connect to a local wireless network on your IsoMatch Tellus.

IsoMatch Wireless (USB-stick) is complementary to the IsoMatch Tellus and makes it easy to connect to a local wireless network, such as your phone’s hot-spot, home network etc.

No additional costs of an internet service provider. When connected via the IsoMatch Wireless you can browse the internet, view the weather, Gmail, Google, etc.

The IsoMatch Eye is the camera option in the IsoMatch product range.

IsoMatch Eye is a camera that has been developed for use with our sophisticated IsoMatch Tellus GO+ and IsoMatch Tellus PRO dual screen terminal. The IsoMatch Eye is switchable from rear view to standard view.

It gives you full control and overview of entire machine operation during day and night, because of its night vision by integrated LED’s. This increases the safety e.g. when reversing the machine or manoeuvring around obstructions.

SMART

Changeable from rear view to standard view

EFFICIENT

Full control and overview of entire machine operation

EASY

Night vision by integrated LED’s

Technical specifications

Technical specifications

Download brochure| iXdrive S642 | iXdrive S652 | iXdrive S661 | ||

|---|---|---|---|---|

| Nominal tank volume (l) | 4250 | 5200 | 6150 | |

| Maximum tank volume (l) | 4500 | 5500 | 6500 | |

| Chemical inductor (l) | 30 | 30 | 30 | |

| Clean water tank (l) | 520 | 520 | 520 | |

| Hand wash tank (l) | 15 | 15 | 15 | |

| Spray boom (m) | HSA 24-30/HSS 27-40/30-24/36-24 | HSA 24-30/HSS 27-40/30-24/36-24 | HSA 24-30/HSS 27-40/30-24/36-24 | |

| Pumps (l/min) | 520 | 520 | 520 | |

| iXclean | iXclean Pro | iXclean Pro | iXclean Pro | |

| Controls for ISOBUS Electronics | Tellus 700/Tellus 1200 | Tellus 700/Tellus 1200 | Tellus 700/Tellus 1200 | |

| Ground clearance (m) | 1.30/1.50/1.70 | 1.30/1.50/1.70 | 1.30/1.50 | |

| Track width - hydraulic adjustable (m) | 1.30 = 1.80-2.25/1.50-1.70 = 2.25-2.95 | 1.30 = 1.80-2.25/1.50-1.70 = 2.25-2.95 | 1.30 = 1.80-2.25/1.50= 2.25-2.95m |

Technical specifications

Technical specifications

Download brochureiXdrive S6 |

|||

Nominal tank capacity (l) |

4.250 |

5.200 |

6.150 |

Maximum tank capacity (l) |

4.500 |

5.500 |

6.500 |

Clean water tank (l) |

520 |

||

Ground clearance (m) |

1.30 / 1.50 / 1.70 |

1.30 / 1.50 |

|

Track width (m) |

1.80 - 2.25 / 2.25 - 2.95 |

||

Spray booms (m) |

HSA 24-30 (2 part folding) / HSS 24-30 (2 part folding) / HSS 32-40 (3 part folding) |

||

Diesel engine |

John Deere PowerTech 250 HP Stage V optional 300 HP Stage V or 250HP Stage II |

||

iXclean Pro, iXflow-E |

Standard |

||