Exacta Spreaders

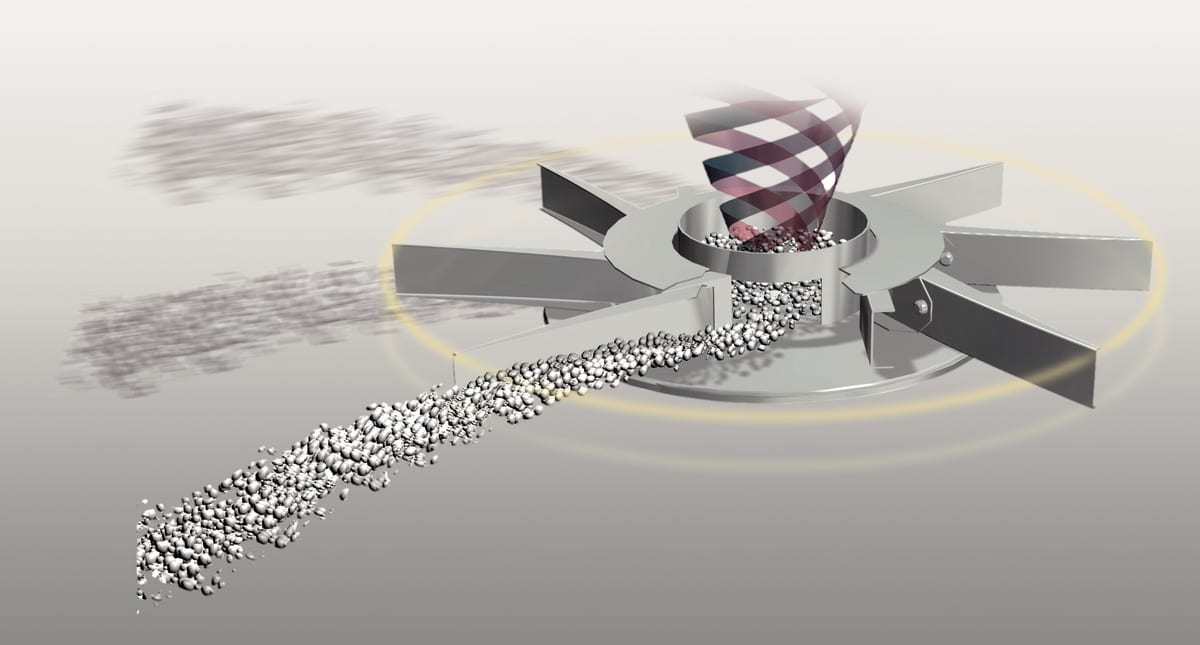

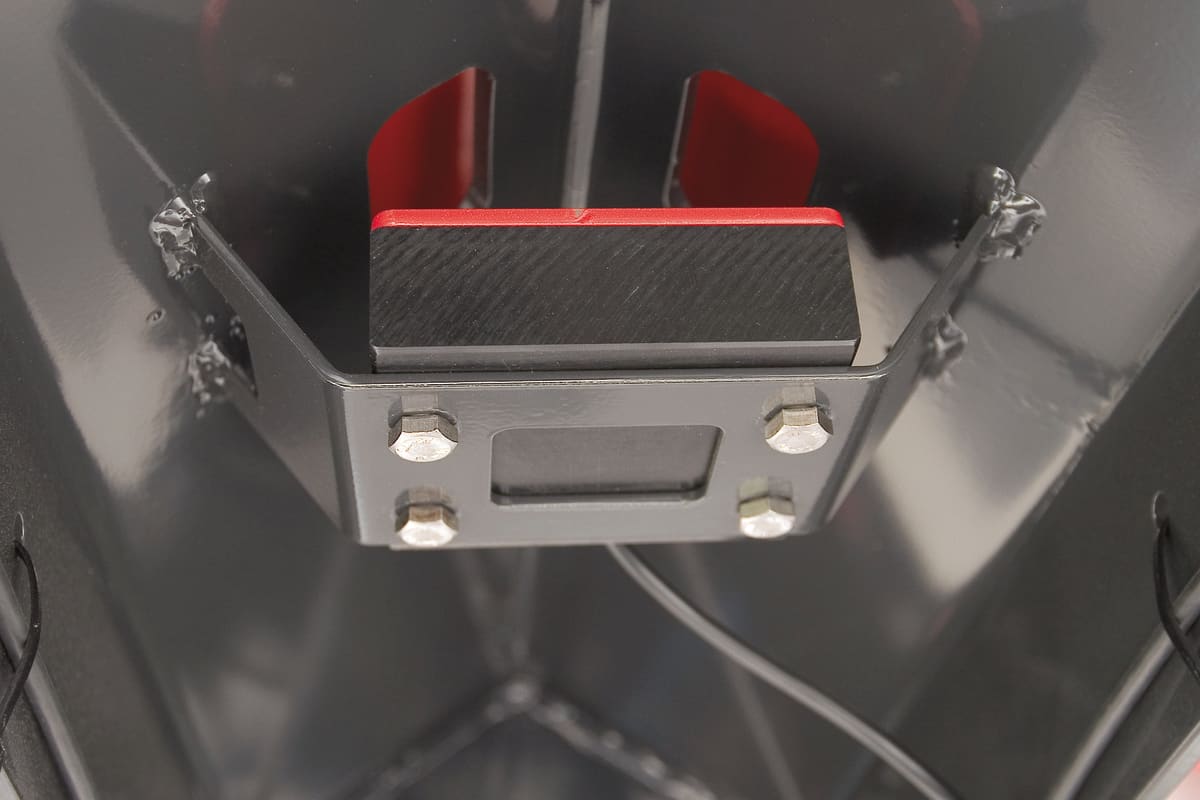

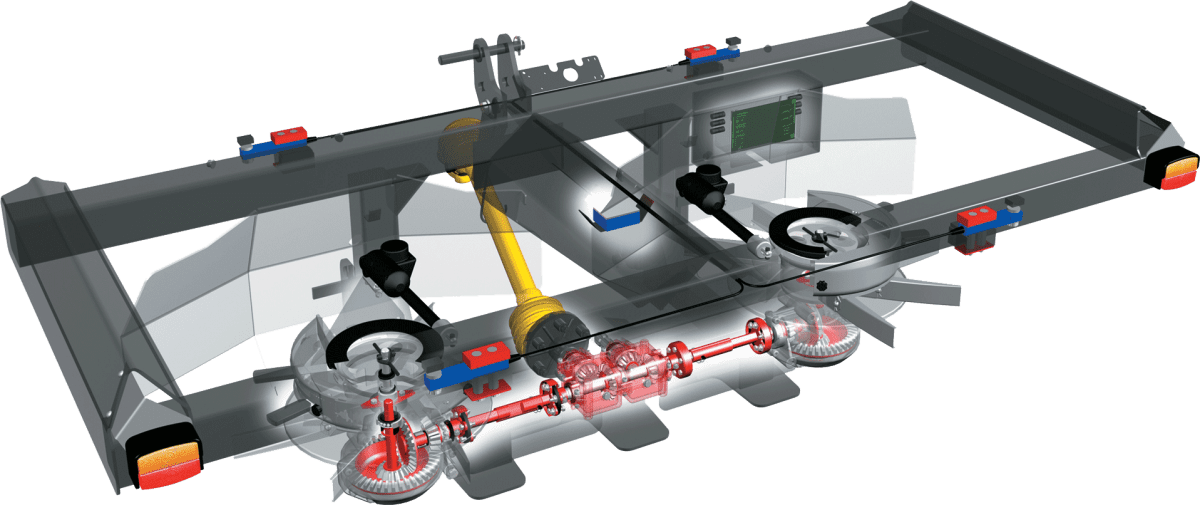

The Kverneland disc spreader creates the most precise spreading pattern. As you are able to quickly and easily optimise the spreading pattern to the actual properties of the used batch of fertiliser instead of generic fertiliser properties, the spreading pattern is much more precise than with other disc spreaders.