Only Original Parts will keep your machine a Kverneland

XHD Hardface reinforced parts

XHD Carbide reinforced parts

The XHD Carbide parts are reinforced by embedding specially shaped Tungsten Carbide tiles on strategic places of the parts that are exposed to hard wearing. These parts can withstand the most demanding conditions.

Up for the task

Kverneland’s XHD Carbide power harrow parts are designed with the most extreme conditions in mind. Abrasive soils put significant stresses on earth wearing parts, resulting in fast wear and regular parts replacement. Thus increasing both costs and downtime. The Kverneland XHD Carbide range is the ideal solution that makes light of tough and demanding conditions. Each part is reinforced by embedding specially shaped Tungsten Carbide tiles on strategic places that are exposed to hard wearing. Especially suited to large farms and contractors, the new XHD range has a lifetime up to 10 times the life* of the standard parts, keeping costs and downtime to a minimum. A cost effective alternative to handle the toughest conditions.

*Based on average test conditions. Depending on soil type, moisture content, machine type, working speed, working depth, machine width and mounting position.

Tungsten Carbide

Tungsten Carbide is one of the hardest materials known to man. Combining carburised Tungsten Powder with soft Cobalt produces a long lasting, hard and durable material able to withstand extreme impacts.

A premium grade of Tungsten Carbide tiles are applied to Kverneland XHD parts to protect key areas against breakage and fast wearing.

The function of each XHD part is different and as such, each experiences different stress levels and impacts. To achieve an acceptable balance between long life verses cost, whilst retaining its high wear characteristics and resistance to impacts - each part has a unique balance between hardness and flexibility.

Heat treated Kverneland Steel

Many reinforced non genuine parts are not heat treated, but rely solely on the Tungsten Carbide protected areas. In Kverneland, we understand the importance of balancing the correct heat and hardness and apply the same tried and proved methods to all our XHD parts.

To allow a frictionless flow of soil, our unique heat treatment produces a harder and smoother surface that lasts longer than softer, untreated steel. The ideal combination of Tungsten Carbide tiles on heat-treated steel gives you the best weapon to face the most extreme soil conditions.

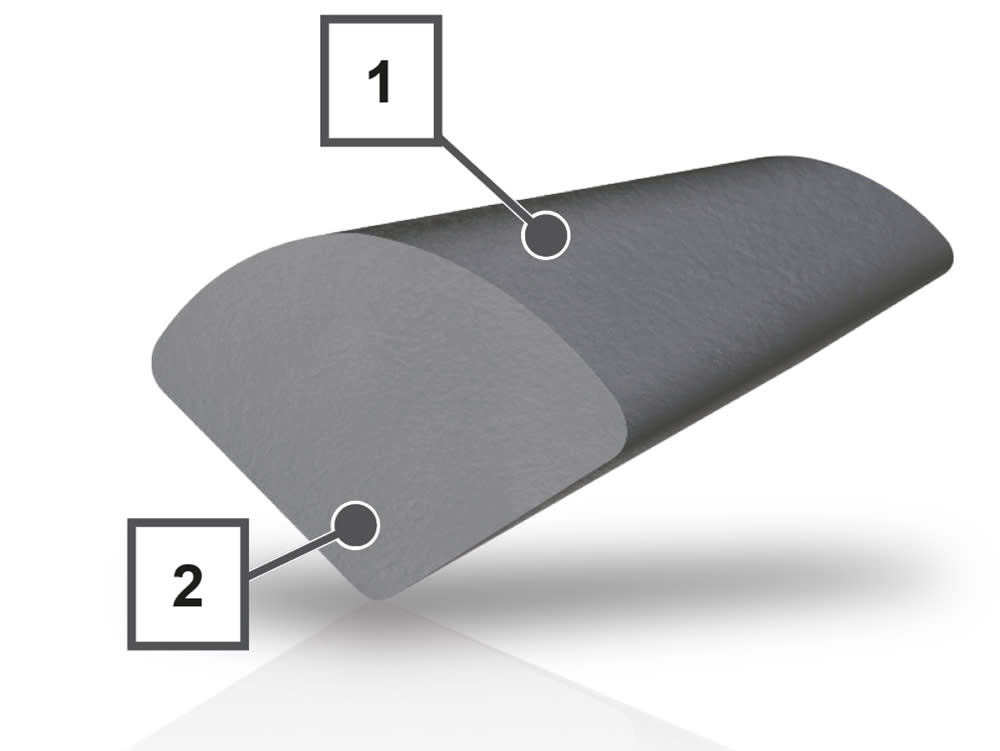

Rounded tiles make the difference

The traditional way of reinforcing power harrow tines is to apply a flat plate to the cutting edge. However, without any protection to the sides, the resistance against the soil significantly increases and the plates become highly vulnerable to heavy impacts.

Kverneland XHD Carbide tines are fitted with uniquely designed rounded tiles to even out the resistance on the tine and are specially countersunk to avoid damage or loss against hard impacts.

1. Rounded edge to even out the pressure.

2. Countersunk into the tine for added durability.

XHD CARBIDE POWER HARROW PARTS

XHD Carbide Tines

The Kverneland XHD tine is reinforced with four premium grade Tungsten Carbide rounded tiles. The specially designed tiles even out the pressure on the cutting edge of the tine to allow optimum penetration and minimal length wear, ensuring a consistent depth and a homogeneous seedbed structure.

The XHD tine is available in two versions; 15mm (H Series) and 18mm (S Series)

XHD CARBIDE POINT 15MM (H Series)

A156183986 - Left

A156184086 - Right

XHD CARBIDE POINT 18MM (S Series)

A156184186 - Left

A156184286 - Right

The balance between strength and cost

Kverneland’s XHD Hardface parts are designed with harsh soil conditions in mind. Abrasive soils put significant stresses on earth wearing parts, resulting in fast wear and regular parts replacement. Thus increasing both costs and downtime.

The XHD Hardface range offer parts with extended lifetime and a strong focus on economy. Reduced wear and longer service life is achieved by adding various wear resistant materials to strategic places of each part, giving the parts up to 4 times the life* of the standard parts. Our different hardfacing methods gives us the possibility to add flexibility to the reinforcement. Materials and processes used to reinforce the XHD Hardface parts are low cost compared to the XHD Carbide range, making it a strong and cost efficient weapon against abrasive soil conditions that causes higher wear.

*Depending on soil type, moisture content, machine type, working speed, working depth, machine width and mounting position.

Tungsten Carbide

Tungsten Carbide is one of the hardest materials known to man. Combining carburised Tungsten Powder with soft Cobalt produces a long lasting, hard and durable material able to withstand extreme impacts.

A premium grade of Tungsten Carbide coating and welding are applied to Kverneland XHD parts to protect key areas against breakage and fast wearing.

The function of each XHD part is different and as such, each experiences different stress levels and impacts. To achieve an acceptable balance between long life verses cost, whilst retaining its high wear characteristics and resistance to impacts - each part has a unique balance between hardness and flexibility.

Heat treated Kverneland Steel

Many reinforced non genuine parts are not heat treated, but rely solely on the Tungsten Carbide protected areas. In Kverneland, we understand the importance of balancing the correct heat and hardness and apply the same tried and proved methods to all our XHD parts.

To allow a frictionless flow of soil, our unique heat treatment produces a harder and smoother surface that lasts longer than softer, untreated steel. The ideal combination of Hardface reinforcement on heat-treated steel gives you the best weapon to face harsh soil conditions.

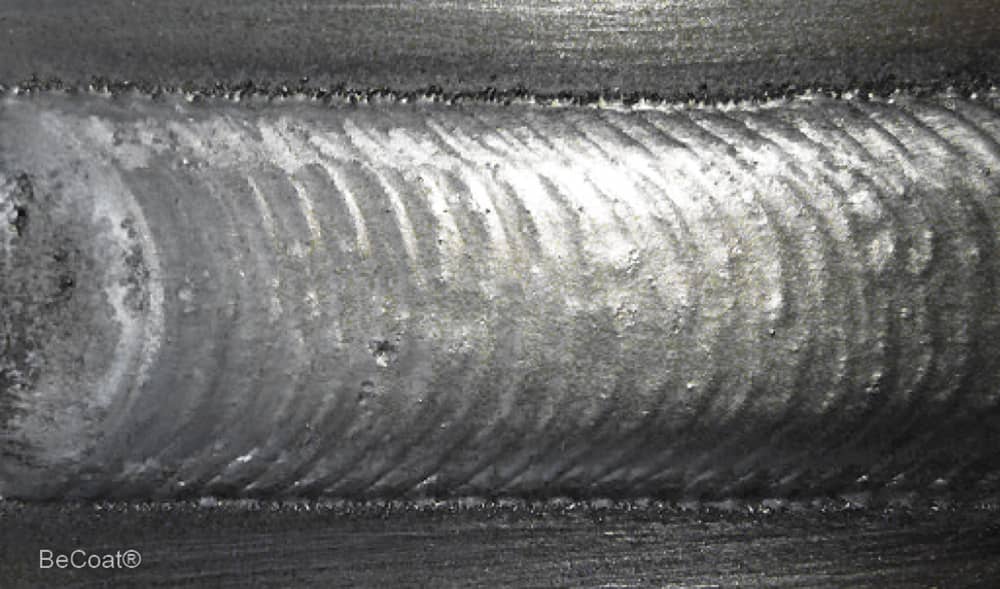

Carbide welding, the tougher hardfacing

The Kverneland XHD Hardface range utilize several methods of reinforcement depending on what is the most effective for each specific part. The toughest reinforcement used in the Hardface range is Carbide welding. This method is applied to parts that are exposed to higher wear and strains, typically parts that goes into the soil.

The steel part is reinforced by adding weld-cladding on areas exposed to higher wearing. A Carbide core welding wire is used to make a strong reinforcement that will add lifetime to the part.

Carbide coating for flexibility

In the Kverneland XHD Hardface range Carbide coating is used for parts that are exposed to medium wear and strains. Carbide coating is an effective yet inexpensive method to add lifetime and flexibility to wearing parts.

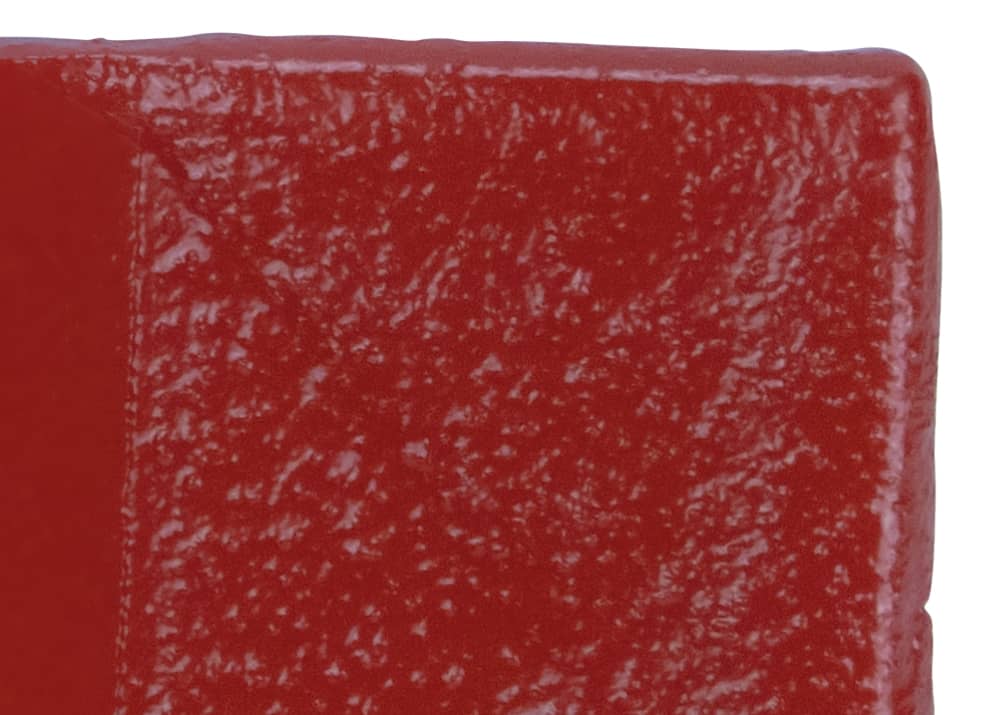

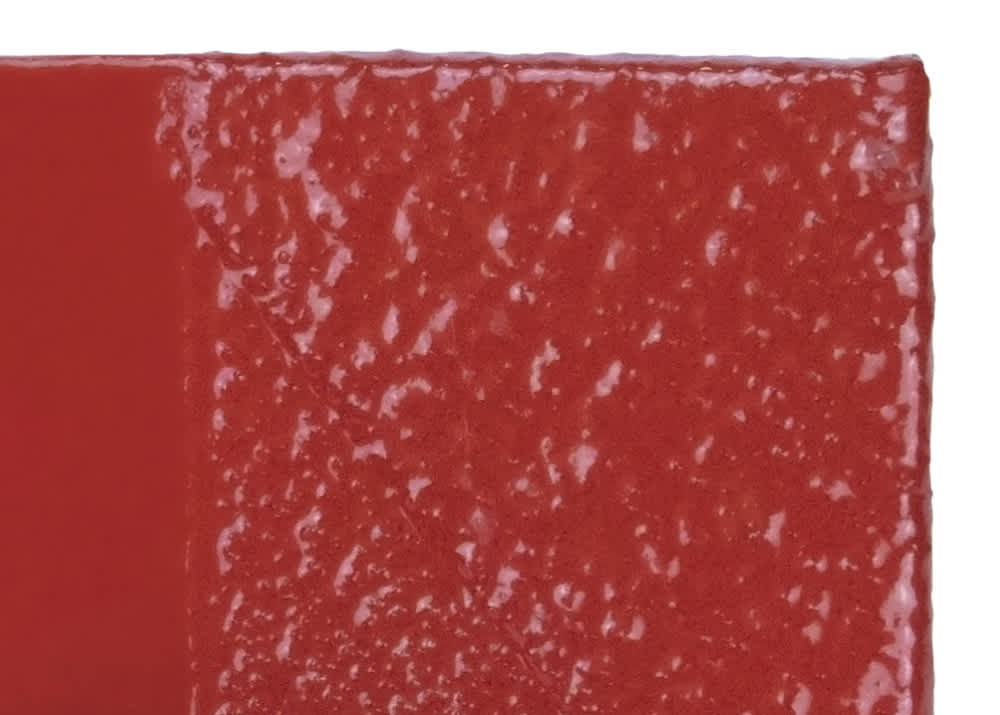

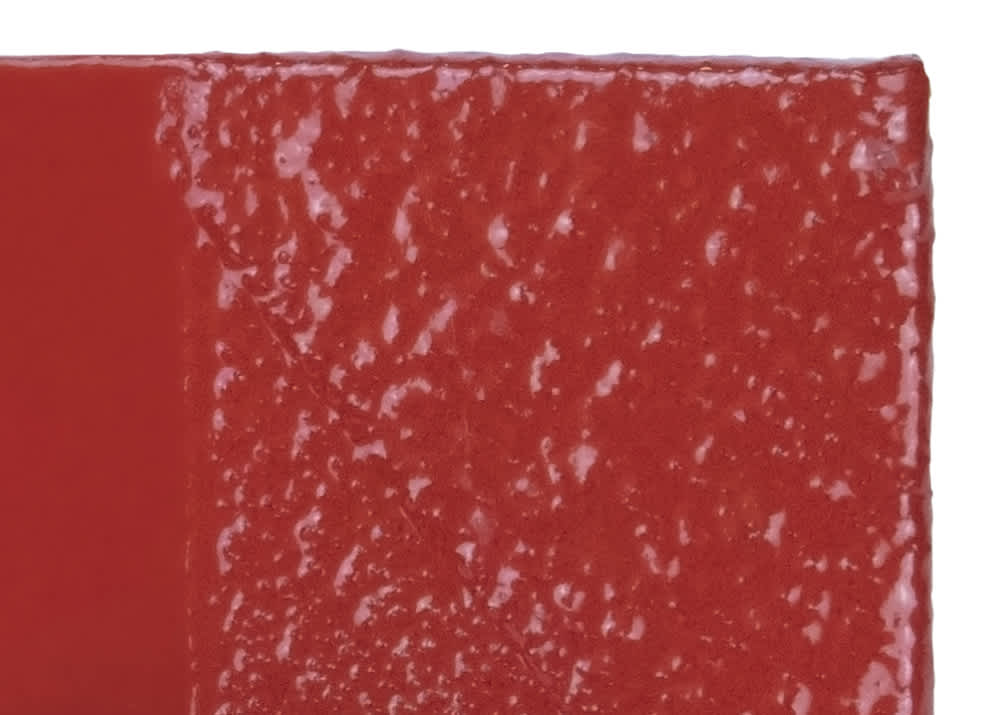

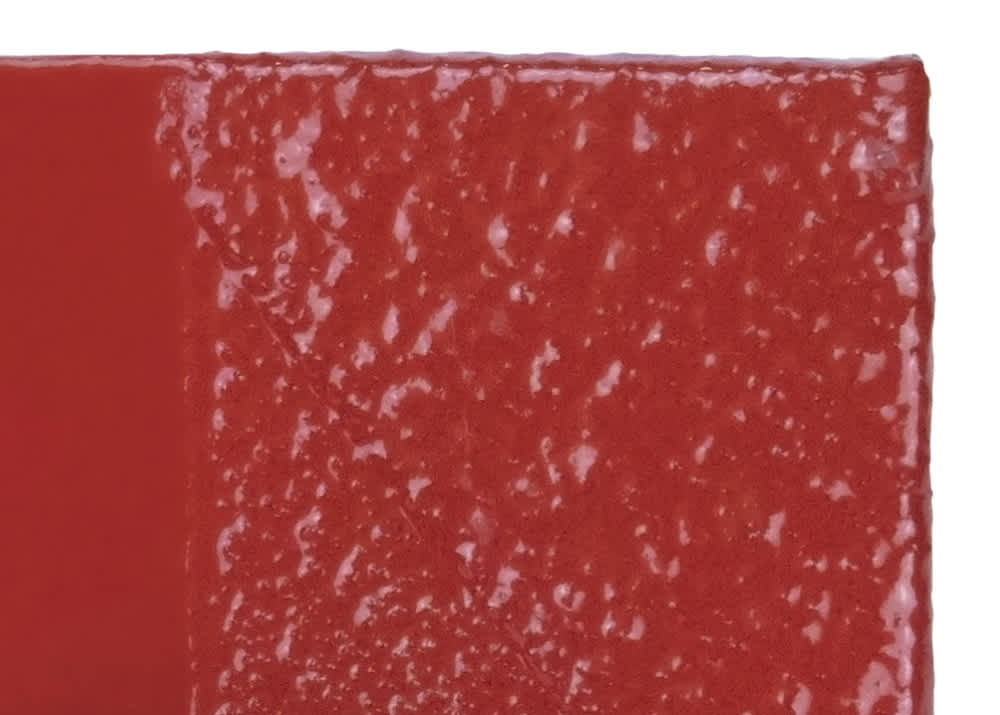

A special paste consisting of small flat carbide plates is heated to become liquid. The XHD parts are then dipped into the liquid to reinforce strategic areas of each part that are exposed to high wear and stress. Parts are coated with several layers of Carbide coating until desired reinforcement is achieved. This creates a hard and flexible surface that will increase lifetime and add flexibility to avoid breakages.

XHD HARDFACE POWER HARROW PARTS

XHD Hardface tines

The Kverneland XHD Hardface tine is reinforced with Carbide welding. The tine is specially designed for the added Carbide welding to bond properly to the part and generate added strength to the cutting edge of the tine. This will allow optimum penetration and minimal length wear throughout the lifetime of the part. The XHD tine is available in two versions; 15mm (H Series) and 18mm (S Series)

XHD HARDFACE TINE 15MM (H Series)

MA46010151S - Left

MA46010150S - Right

XHD HARDFACE TINE 18MM (S Series)

MA44010151S - Left

MA44010150S - Right

XHD Hardface tines

The Kverneland XHD Hardface tine is reinforced with Carbide welding. The tine is specially designed for the added Carbide welding to bond properly to the part and generate added strength to the cutting edge of the tine. This will allow optimum penetration and minimal length wear throughout the lifetime of the part.

The XHD tine is available in 12mm (M Series)

XHD HARDFACE TINE 12MM (M Series)

MAE020146S - Left

MAE010146S - Right

XHD scraper Flexline roller

T1he Kverneland XHD Hardface adjustable Scraper is reinforced on the cutting edge with several layers of Carbide coating. This coating will extend the lifetime of the scraper and ensure to keep the machine blockage free during operation.

XHD HARDFACE SCRAPER

A137097894

XHD scraper Actiline

The Kverneland XHD Hardface adjustable and reversible Scraper is reinforced with several layers of Carbide coating on both cutting edges. The coating thoughtfully placed with different thicknesses, based on how we know the scraper is wearing down over time. Carbide coating will extend the lifetime of the scraper and ensure to keep the machine blockage free during operation.

XHD HARDFACE RING ROLLER SCRAPER

A156174594

XHD scraper for packer roller

The Kverneland XHD Hardface adjustable and reversible Scraper is reinforced with several layers of Carbide coating on both cutting edges. The coating thoughtfully placed with different thicknesses, based on how we know the scraper is wearing down over time. Carbide coating will extend the lifetime of the scraper and ensure to keep the machine blockage free during operation.

XHD HARDFACE SCRAPER - Ø500, 575

RF23749

XHD scraper Actiline (2022)

The Kverneland XHD Hardface adjustable and reversible Scraper is reinforced with several layers of Carbide coating on both cutting edges. The coating thoughtfully placed with different thicknesses, based on how we know the scraper is wearing down over time. Carbide coating will extend the lifetime of the scraper and ensure to keep the machine blockage free during operation.

XHD HARDAFACE SCRAPER - 65MM

A156311794

XHD scraper for packer roller

The Kverneland XHD Hardface adjustable and reversible Scraper is reinforced with several layers of Carbide coating on both cutting edges. The coating thoughtfully placed with different thicknesses, based on how we know the scraper is wearing down over time. Carbide coating will extend the lifetime of the scraper and ensure to keep the machine blockage free during operation.

XHD HARDFACE SCRAPER - 90MM

A156311094

Original Parts when you need them!

DISTRIBUTION CENTRE METZ - SERVICE 24/7

Time is money, and we know the importance of receiving the right parts at the right time! Your Kverneland dealer is supported by a massive distribution network to supply you with exactly what you need, when you need it.

Our main distribution centre Metz warehouse is located in Thionville, France. A strategic location for distributing parts to all corners of the world. With over 70.000 parts in stock and 24/7 service, we are ready to supply you with parts – at any time!